Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Veneer Measurer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

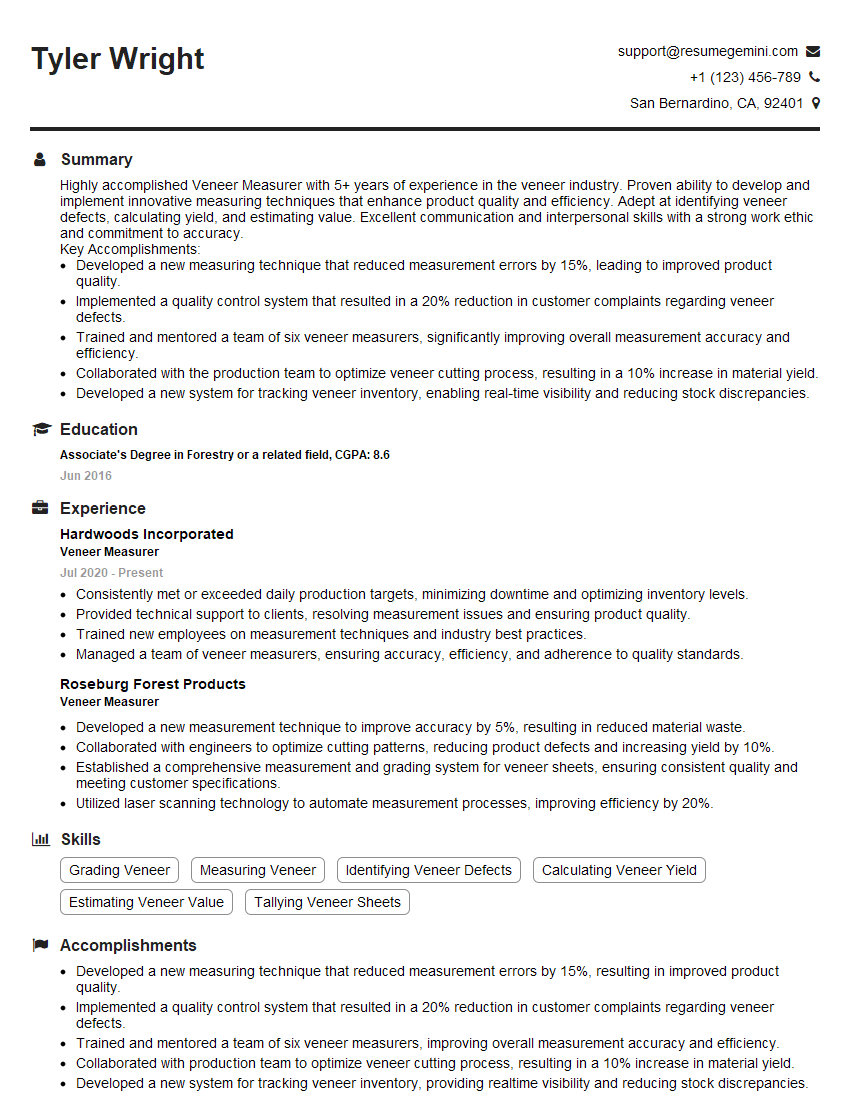

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Measurer

1. What tools do you typically use for veneer measurement?

- Digital caliper

- Veneer measuring tape

- Surface gauge

- Micrometer

2. What are the key factors you consider when measuring veneer thickness?

Moisture Content

- Variations in thickness due to swelling or shrinking of the veneer

- Need to take moisture content into account when determining the final thickness

Grain Direction

- Measuring thickness perpendicular to the grain for accurate results

- Avoid measuring thickness parallel to the grain, as it can provide distorted readings

Surface Roughness

- Taking multiple measurements to account for surface variations

- Using appropriate measuring tools and techniques to obtain accurate thickness readings

3. How do you determine the grain direction of a veneer sheet?

- Visually inspecting the veneer’s surface to identify the parallel lines created by the wood fibers

- Running a finger or a sharp object along the surface to feel the direction of the grain

- Using a magnifying glass to examine the veneer’s cellular structure and determine the grain direction

4. What are the different types of defects that you typically encounter in veneer sheets and how do you measure them?

- Cracks: Using a caliper to measure the length and width of the crack

- Knots: Measuring the diameter of the knot and its depth using a micrometer or surface gauge

- Splits: Measuring the length and depth of the split using a veneer measuring tape or caliper

- Holes: Measuring the diameter and depth of the hole using a caliper or micrometer

5. How do you calculate the square footage of a veneer sheet?

- Measuring the length and width of the veneer sheet using a veneer measuring tape

- Multiplying the length and width to calculate the area in square feet

- For irregular shapes, dividing the area into smaller regular shapes and calculating the area of each shape

6. What are the industry standards for veneer measurements and grading?

- American National Standards Institute (ANSI) standards

- International Organization for Standardization (ISO) standards

- Grading based on factors such as thickness, color, grain, and defects

7. How do you handle veneer sheets to minimize damage during measurement?

- Wearing gloves to prevent fingerprints and oils from transferring to the veneer

- Using clean and dry measuring tools to avoid scratching or damaging the veneer

- Handling the veneer carefully to prevent bending or tearing

- Storing the veneer in a controlled environment to prevent warping or moisture damage

8. What software or tools do you use to record and manage veneer measurement data?

- Specialized veneer measurement software

- Spreadsheets or databases for recording data

- Barcode scanners for tracking and identifying veneer sheets

9. How do you stay up-to-date with the latest techniques and developments in veneer measurement?

- Attending industry conferences and workshops

- Reading trade publications and research papers

- Seeking training from equipment manufacturers and industry experts

10. What is your understanding of the role of a veneer measurer in quality control and inventory management?

- Ensuring that veneer meets customer specifications and industry standards

- Providing accurate data for inventory management and production planning

- Identifying and documenting defects to facilitate repairs or replacements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Measurer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Measurer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Veneer Measurer is the backbone of any veneer manufacturing or trading company, responsible for the accurate measurement and grading of veneer sheets.

1. Measurement and Verification

Veneer Measurers are responsible for the precise measurement of veneer sheets using specialized tools and equipment.

- Employing measuring tapes, calipers, and digital scanners to determine the length, width, and thickness of veneer sheets

- Verifying the accuracy of measurements to ensure compliance with industry standards and customer specifications

2. Grading and Evaluation

Evaluates the quality of veneer sheets based on various factors, determining their grade and value.

- Inspecting veneer sheets for defects, such as knots, splits, discoloration, and imperfections

- Applying established grading rules and criteria to assign a grade to each sheet, which determines its market value

3. Record-Keeping and Documentation

Meticulously maintaining accurate records of measurements, grading results, and other relevant data is crucial.

- Documenting all measurement and grading information to facilitate inventory management, pricing, and customer invoicing

- Maintaining a comprehensive database of veneer inventory, including details on quantity, grade, and availability

4. Quality Control

Veneer Measurers contribute to the overall quality control process within the company.

- Monitoring incoming veneer sheets for compliance with specifications and rejecting any substandard materials

- Providing feedback to suppliers and production teams to improve the quality of veneer sheets

Interview Tips

Interview preparation is essential for any job seeker. Here are some key tips to help you ace your Veneer Measurer interview:

1. Research the Company and the Industry

Research the veneer manufacturing or trading company you are interviewing with, and the veneer industry as a whole. This will show the interviewer that you are genuinely interested in the position and the company’s business.

- Visit the company’s website to learn about their products, services, and values

- Read industry publications and articles to stay up-to-date on market trends and technologies

2. Practice your Measurement Techniques

Interviewers may ask you to demonstrate your measurement techniques during the interview. Practice using measuring tapes, calipers, and digital scanners beforehand to ensure you are comfortable and accurate.

- Set up a practice area with various veneer samples to measure

- Time yourself to improve your efficiency and accuracy

3. Familiarize Yourself with Grading Standards

Veneer Measurers should have a thorough understanding of the grading rules and criteria used in the industry. Study the different grades of veneer and the factors that determine each grade.

- Obtain copies of industry grading standards, such as the American National Standards Institute (ANSI) or the Hardwood Veneer Association (HVA) standards

- Practice grading veneer samples using these standards

4. Highlight Your Experience and Skills

In the interview, emphasize your experience and skills in veneer measurement, grading, and record-keeping. Quantify your accomplishments and provide specific examples of your work.

- Discuss your experience using measuring tools and equipment

- Provide examples of how you have successfully graded and evaluated veneer sheets

5. Ask Informed Questions

Asking well-thought-out questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions that demonstrate your knowledge of the industry and your interest in the company.

- Ask about the company’s veneer sourcing and production processes

- Inquire about opportunities for professional development and advancement within the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Veneer Measurer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.