Are you gearing up for a career in Veneer Press Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Veneer Press Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

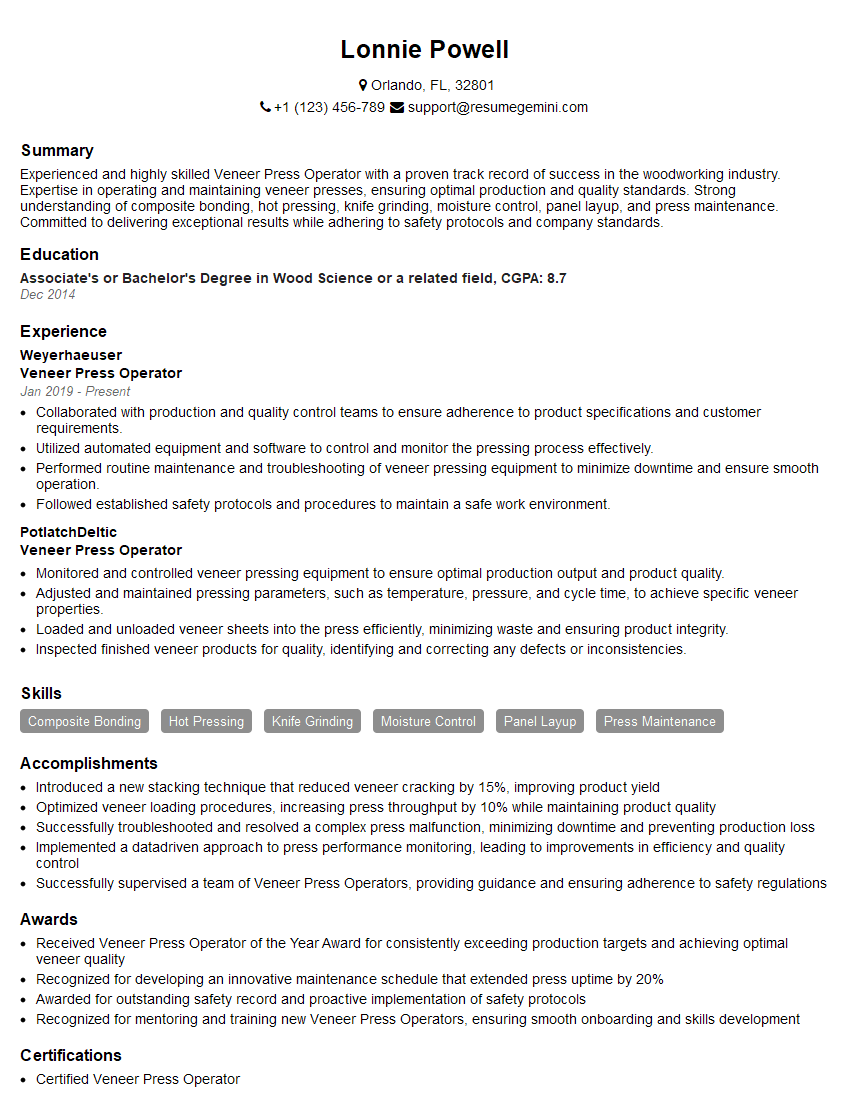

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Press Operator

1. Describe the process of preparing and loading face and back veneers onto the press?

The process of preparing and loading face and back veneers onto the press involves several key steps:

- Selecting and inspecting veneers: Veneers are carefully chosen based on the desired grain, color, and thickness. They are inspected for any defects or imperfections.

- Applying adhesive: A thin layer of adhesive is applied to the veneer’s surface, ensuring even coverage.

- Loading face and back veneers: The prepared veneers are loaded onto the press, with the face veneer placed on top and the back veneer on the bottom.

- Aligning and registering veneers: The veneers are precisely aligned and registered to achieve the desired pattern and grain matching.

- Applying pressure and heat: Pressure and heat are applied to the veneers, causing the adhesive to bond them together.

2. How do you determine the appropriate press settings for various veneer combinations?

Factors to Consider

- Wood species: Different wood species have varying density and hardness, which affects the required pressure and temperature.

- Veneer thickness: Thicker veneers require higher pressure to ensure proper bonding.

- Adhesive type: The type of adhesive used dictates the required temperature.

Setting Determination

- Pressure: Use manufacturer’s recommendations or conduct trial runs to determine optimal pressure for each combination.

- Temperature: Refer to adhesive specifications for the appropriate temperature range.

- Press time: Adjust the press time based on the veneer thickness and desired bond strength.

3. Explain the importance of moisture content control in veneer pressing.

Moisture content control is crucial in veneer pressing for several reasons:

- Adhesive bond strength: Excessive moisture can weaken the adhesive bond between veneers.

- Veneer warping: Uneven moisture distribution can cause veneers to warp or buckle during or after pressing.

- Dimensional stability: Controlling moisture content helps maintain the veneer’s dimensional stability, preventing shrinkage or expansion.

- Press efficiency: Moist veneers require longer press times to achieve proper bonding.

4. Describe the quality control measures you implement to ensure the production of high-quality veneered panels.

- Raw material inspection: Inspecting veneers for defects, grain matching, and moisture content.

- Adhesive quality control: Ensuring proper adhesive application and bond strength.

- Press parameter monitoring: Recording and analyzing press settings to ensure consistency.

- Panel inspection: Visually inspecting panels for surface defects, grain matching, and overall quality.

- Destructive testing: Conducting destructive tests, such as shear strength tests, to verify the panel’s integrity.

5. How do you troubleshoot common problems that occur during veneer pressing, such as blisters, voids, and delamination?

Blisters

- Causes: Excess moisture trapped in the veneers.

- Solutions: Control moisture content, increase press temperature, or extend press time.

Voids

- Causes: Incomplete adhesive coverage, improper press pressure.

- Solutions: Inspect adhesive application, adjust press pressure settings.

Delamination

- Causes: Poor adhesive bond, high moisture content.

- Solutions: Use high-quality adhesive, control moisture content, increase press time or temperature.

6. How do you maintain and calibrate the veneer press to ensure optimal performance?

- Regular cleaning and maintenance: Cleaning the press platens, heating elements, and hydraulic components.

- Calibration: Using precision gauges or calibrated tools to ensure accurate pressure readings and temperature control.

- Preventive maintenance: Performing scheduled inspections and replacements of critical components to prevent breakdowns.

7. What safety measures do you follow when operating the veneer press?

- Proper clothing and PPE: Wearing flame-resistant clothing, safety glasses, and appropriate hand protection.

- Machine guarding: Ensuring all moving parts are properly guarded.

- Electrical safety: Verifying proper grounding and using lock-out/tag-out procedures.

- Emergency procedures: Being familiar with emergency stop buttons and evacuation protocols.

8. Describe your experience in optimizing press efficiency and reducing production costs.

Here are some strategies I have implemented to optimize press efficiency and reduce production costs:

- Maximizing press utilization: Scheduling production runs to minimize press downtime and maximize throughput.

- Reducing setup time: Using quick-release mechanisms, pre-loading veneers, and optimizing tool changes.

- Batching similar orders: Grouping orders with similar veneers and press settings to reduce changeover time.

- Implementing lean manufacturing principles: Eliminating waste and streamlining processes to improve efficiency.

9. How do you stay up-to-date on the latest advancements in veneer pressing technology?

- Attending trade shows and industry events: Exhibitors showcase new technologies and innovations.

- Reading industry publications and articles: Staying informed about technical advancements and best practices.

- Networking with industry professionals: Exchanging knowledge and learning about cutting-edge techniques.

- Training and workshops: Participating in technical training programs to enhance skills and stay updated.

10. What are your career aspirations and how do you see this role contributing to your professional growth?

My career aspiration is to become a highly skilled and experienced Veneer Press Operator. I believe this role can significantly contribute to my professional growth:

- Develop specialized skills: Operating and maintaining a veneer press requires specific technical skills that I am eager to master.

- Enhance my understanding of wood technology: This role involves working with different wood species and understanding their properties, which will broaden my knowledge.

- Gain valuable industry experience: Working in a production environment will provide me with practical experience and exposure to the industry.

- Advance my career: By excelling in this role, I can demonstrate my capabilities and progress to more senior positions in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Veneer Press Operators play a vital role in the manufacturing process, producing high-quality veneer sheets essential for various industries.

1. Press Operation

Veneer Press Operators are responsible for efficiently operating and maintaining veneer presses to produce veneer sheets with the desired specifications.

- Setting up and operating veneer presses according to established procedures and quality standards.

- Monitoring and adjusting press parameters such as temperature, pressure, and cycle times to ensure the production of high-quality veneer sheets.

2. Veneer Handling and Inspection

Veneer Press Operators handle and inspect veneer sheets throughout the production process to ensure their quality and integrity.

- Handling veneer sheets with care, minimizing damage or defects during loading, unloading, and storage.

- Inspecting veneer sheets for quality, identifying any defects or imperfections, and taking corrective actions as necessary.

3. Equipment Maintenance and Troubleshooting

Veneer Press Operators are responsible for maintaining and troubleshooting veneer presses to ensure their optimal performance and prevent costly downtime.

- Performing daily and routine maintenance tasks on veneer presses, including cleaning, lubrication, and visual inspections.

- Identifying and troubleshooting equipment problems, diagnosing the root cause, and taking appropriate corrective actions.

4. Production Monitoring and Adjustment

Veneer Press Operators monitor production processes and make adjustments as needed to optimize output and meet production targets.

- Monitoring production rates and quality, identifying any deviations from established standards, and taking corrective actions.

- Adjusting veneer press parameters and operating conditions to optimize production efficiency and minimize waste.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your Veneer Press Operator interview:

1. Research the Company and Position

It’s essential to research the company you’re applying to and the specific Veneer Press Operator position. This will help you understand the company’s values, culture, and the requirements of the role.

- Visit the company website to learn about their history, mission, and products.

- Read industry news and articles to stay updated on the latest trends and developments.

2. Practice Answering Common Interview Questions

Many common interview questions can be anticipated. Practicing your answers will help you appear confident and prepared during the interview itself.

- Tell me about your experience operating veneer presses.

- How do you ensure the production of high-quality veneer sheets?

- Describe a time when you had to troubleshoot a problem with a veneer press.

3. Highlight Your Skills and Experience

When answering interview questions, focus on highlighting your skills and experience that are relevant to the Veneer Press Operator position. Use specific examples to demonstrate your abilities.

- Example: “In my previous role, I was responsible for operating and maintaining a variety of veneer presses, including hydraulic and electric models. I consistently met or exceeded production targets while maintaining high-quality standards.”

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This will show the interviewer that you respect their time and are serious about the position.

5. Be Enthusiastic and Ask Questions

Showcase your enthusiasm for the position and the company. Ask thoughtful questions about the role, the company culture, and the industry.

- Example: “I’m particularly interested in your company’s commitment to sustainability. Can you tell me more about your initiatives in this area?”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Veneer Press Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.