Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Veneer Puller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

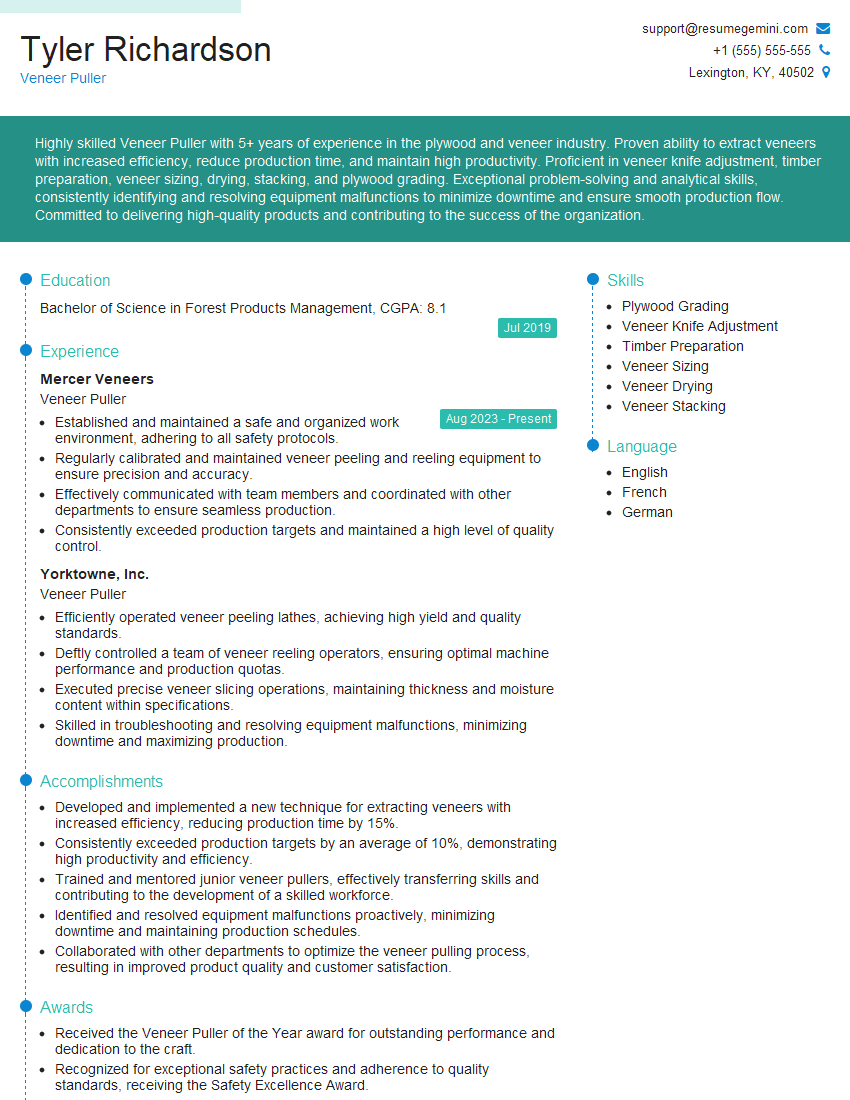

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Puller

1. What are the different types of veneer pulling machines available in the market?

- Roller Veneer Peelers

- Stay Log Veneer Peelers

- Slicer Veneer Machines

- Lathe Veneer Machines

- Drum Veneer Peelers

2. How do you determine the correct veneer thickness for a specific application?

Factors to Consider:

- End use of the veneer

- Wood species and its properties

- Grain pattern and orientation

- Thickness requirements for gluing and finishing

3. Describe the process of conditioning veneer before peeling.

- Steaming or boiling the logs to soften the wood

- Soaking the logs in water to increase moisture content

- Heating the logs in a kiln to remove excess moisture

- Clipping the ends of the logs to ensure a clean cut

4. What are the common defects that can occur during veneer peeling?

- Tearing or splitting

- Checking or cracking

- Wavy or uneven surface

- Knots or inclusions

- Pitch pockets or resin streaks

5. How do you maintain and troubleshoot veneer pulling machines?

Maintenance:

- Regular cleaning and lubrication

- Blade sharpening and replacement

- Checking and adjusting machine settings

Troubleshooting:

- Identifying and resolving electrical issues

- Diagnosing and repairing mechanical failures

- Calibrating and adjusting sensors

6. What are the safety precautions to be taken while operating veneer peeling machines?

- Wear appropriate personal protective equipment

- Follow proper machine operation procedures

- Keep the work area clean and organized

- Be aware of potential hazards and risks

- Receive proper training and certification

7. How do you handle and store veneer after peeling?

Handling:

- Use proper lifting techniques

- Protect the veneer from damage

- Store veneer in a flat and stable position

Storage:

- Control temperature and humidity

- Stack veneer properly to prevent warping

- Protect veneer from sunlight and moisture

8. What are the different grades of veneer available?

- Architectural Grade Veneer

- Cabinet Grade Veneer

- Commercial Grade Veneer

- Specialty Grade Veneer

9. What is the difference between rotary cut and sliced veneer?

- Rotary Cut Veneer: Produced by peeling logs on a lathe

- Sliced Veneer: Produced by slicing logs on a slicing machine

Comparison:

- Grain Pattern

- Consistency

- Thickness

- Price

10. How do you calculate the yield of veneer from a log?

- Consider log diameter and length

- Factor in veneer thickness and recovery rate

- Use mathematical formulas or industry-standard tables

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Veneer Puller is responsible for operating machines that peel thin layers of wood, known as veneers, from logs. Here are their key responsibilities:

1. Veneer Cutting

Veneer Pullers operate automated or semi-automated machines to cut thin slices of veneer from logs. They ensure proper alignment, adjust machine settings, and monitor the cutting process.

- Operate peeling and slicing machines

- Adjust machine settings for thickness and quality

2. Veneer Inspection

Veneer Pullers inspect the produced veneers for defects such as knots, cracks, and discolorations. They grade veneers based on quality and make necessary adjustments to the cutting process.

- Identify and mark defects on veneers

- Determine the grade and quality of veneers

3. Maintenance and Calibration

Veneer Pullers perform regular maintenance on cutting machines to ensure optimal performance. They lubricate parts, change blades, and make necessary adjustments.

- Lubricate, adjust, and maintain machines

- Calibrate equipment for precise cutting

4. Material Handling

Veneer Pullers handle large logs and bundles of veneer during the cutting and inspection process. They use forklifts, cranes, and other equipment to move materials safely.

- Load and unload logs and veneer bundles

- Operate forklifts and other equipment

Interview Tips

Preparing for a Veneer Puller interview requires an understanding of the job’s requirements and the industry. Here are some tips to help you ace the interview:

1. Research the Veneer Industry

Familiarize yourself with the veneer manufacturing process, including different cutting techniques, types of veneer, and industry standards. This knowledge will demonstrate your interest and understanding of the field.

- Research the equipment and technology used in veneer peeling

- Understand the various uses and applications of veneers

2. Highlight Relevant Experience

Emphasize any previous experience operating machinery, handling logs, or working in a manufacturing environment. If you have experience in woodworking or carpentry, it can also be beneficial.

- Discuss your expertise in operating cutting machines

- Mention your ability to identify and grade different types of wood

3. Practice Problem-Solving

Veneer Pullers may encounter issues during the cutting process. Prepare for hypothetical scenarios by thinking through potential problems and developing solutions. This demonstrates your analytical skills and ability to adapt.

- Prepare for questions about how to handle common machine malfunctions

- Discuss your decision-making process when dealing with defective veneers

4. Show Enthusiasm for the Industry

Veneer manufacturing is a specialized field. Express your interest in the industry and your desire to learn more. Highlight your passion for working with wood and contributing to the production of high-quality veneers.

- Research the history and significance of veneer in the furniture industry

- Discuss your interest in sustainable forestry practices

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Veneer Puller role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.