Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Veneer Sawyer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

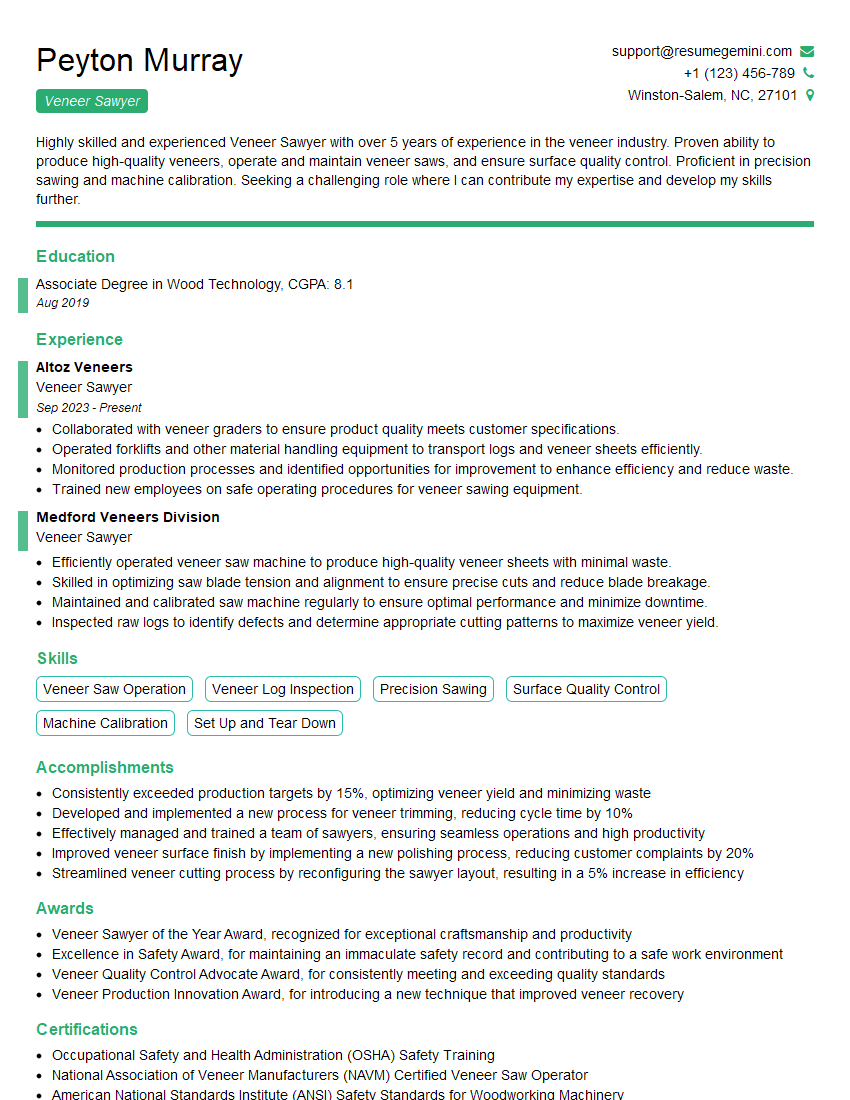

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Sawyer

1. How do you ensure the quality of veneers produced?

To ensure the quality of veneers produced, I follow a meticulous process that involves:

- Log Selection: I carefully select logs based on their size, grain pattern, and absence of defects.

- Debarking and Cutting: I expertly remove the bark and cut the logs into sheets of the desired thickness using specialized cutting equipment.

- Peeling: I operate a lathe to peel off veneer sheets consistently, ensuring uniform thickness and surface quality.

- Clipping and Drying: I clip the sheets to remove any imperfections and then dry them under controlled temperature and humidity to prevent warping.

- Grading and Sorting: I meticulously grade and sort the veneers based on their quality, color, and other characteristics.

2. What types of veneer cutting machines are you familiar with?

- Rotary Veneer Lathe: I am highly proficient in operating a rotary lathe to peel thin, continuous veneer sheets from cylindrical logs.

- Slicer: I have experience using a slicer to produce veneers from flat-sawn lumber, achieving accurate thickness and grain matching.

- Guillotine Clipper: I am skilled in using a guillotine clipper to cut veneers to the desired dimensions and remove defects.

3. How do you prevent and correct common veneer defects?

I take proactive measures to prevent common veneer defects by:

- Selecting high-quality logs: Minimizing defects at the source.

- Proper cutting techniques: Using sharp blades and ensuring proper cutting angles.

- Careful drying: Controlling temperature and humidity to prevent warping and splitting.

To correct defects, I utilize various techniques such as:

- Veneer Patching: Inserting small pieces of veneer to repair holes or imperfections.

- Edge Gluing: Joining veneer strips to create wider sheets or correct edge defects.

- Crack and Split Repair: Using specialized adhesives and clamps to mend cracks and splits.

4. What safety precautions do you observe when working with veneer machinery?

- Proper PPE: Always wearing safety glasses, earplugs, and gloves.

- Regular Inspections: Checking equipment daily for wear and tear or potential hazards.

- Guarding: Ensuring all moving parts are properly guarded to prevent accidents.

- Awareness of Surroundings: Maintaining a clear work area and being mindful of others nearby.

- Emergency Procedures: Knowing the emergency stop procedures and evacuation routes.

5. How do you optimize the yield and quality of veneers?

I optimize veneer yield and quality through several techniques:

- Log Selection and Preparation: Selecting logs with minimal defects and properly preparing them for cutting.

- Efficient Cutting Techniques: Utilizing sharp blades and employing proper cutting angles to minimize waste.

- Optimizing Cutting Patterns: Arranging logs on the lathe to maximize veneer recovery and minimize cross-grain.

- Proper Drying: Controlling temperature and humidity during drying to prevent warping and splitting, which can reduce yield.

- Defect Control: Identifying and addressing defects promptly to prevent them from affecting larger pieces of veneer.

6. What are the different types of veneer and their applications?

There are various types of veneers with unique characteristics and applications:

- Wood Veneer: Real wood veneer cut from different tree species, offering a natural and unique aesthetic.

- Decorative Veneer: Veneer with decorative patterns or colors applied to the surface, used for furniture and interior designs.

- Architectural Veneer: Durable veneer used in exterior applications such as cladding and facades.

- Reconstructed Veneer: Veneer made by bonding thin layers of wood, providing consistent quality and reduced cost.

- Flexible Veneer: Veneer that can be bent or curved, suitable for complex surfaces or furniture.

7. How do you ensure the proper bonding of veneer to substrates?

Ensuring proper bonding of veneer to substrates is crucial for the durability and quality of the finished product:

- Surface Preparation: Preparing the substrate by sanding or cleaning to remove any contaminants or unevenness.

- Adhesive Selection: Choosing the appropriate adhesive based on the type of veneer and substrate.

- Application Technique: Evenly applying the adhesive to both surfaces and ensuring proper coverage.

- Pressure Application: Applying sufficient pressure during bonding to ensure complete adhesion.

- Curing Time: Allowing ample time for the adhesive to cure and reach full strength.

8. What are the common maintenance tasks for veneer machinery?

Regular maintenance is essential to ensure the longevity and efficiency of veneer machinery:

- Blade Sharpening: Sharpening cutting blades regularly to maintain optimal performance.

- Lubrication: Lubricating moving parts to reduce friction and wear.

- Cleaning: Removing sawdust and debris from machinery to prevent malfunctions.

- Electrical Inspections: Checking electrical connections and components for safety and performance.

- Tension Adjustments: Adjusting tension settings to ensure proper veneer cutting and peeling.

9. What knowledge do you have of sustainable veneer production practices?

I am aware of the importance of sustainable veneer production practices:

- Responsible Log Sourcing: Ensuring logs are harvested from well-managed forests with reforestation practices.

- Minimizing Waste: Utilizing efficient cutting techniques and optimizing veneer yield to reduce waste.

- Veneer Recycling: Exploring methods to recycle veneer scraps and minimize environmental impact.

- Emissions Control: Implementing measures to reduce emissions and protect the environment.

10. How do you stay updated on the latest advancements in veneer production technology?

- Industry Publications and Journals: Reading industry publications and journals to keep abreast of new techniques and technologies.

- Trade Shows and Conferences: Attending trade shows and conferences to witness firsthand the latest developments.

- Online Resources: Utilizing online resources such as industry forums and webinars to gather information and connect with peers.

- Collaboration with Peers: Exchanging knowledge and experiences with other veneer professionals to stay informed about best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Sawyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Sawyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Veneer Sawyers are responsible for operating saws to cut logs into thin sheets of veneer, which are used to make plywood, furniture, and other wood products. Their primary duties include:

1. Operating Veneer Saws

Veneer Sawyers set up and operate veneer saws, which are highly specialized machines that use sharp blades to slice logs into thin sheets. They must be able to adjust the saw settings to achieve the desired thickness and quality of veneer.

- Calibrating and maintaining veneer saws to ensure optimal performance.

- Inspecting logs for defects and selecting suitable logs for veneering.

2. Ensuring Veneer Quality

Veneer Sawyers monitor the veneer cutting process to ensure that the sheets meet the required specifications. They inspect the veneer for defects such as cracks, splits, or uneven thickness. They also make adjustments to the saw settings as needed to maintain the desired quality.

- Grading and sorting veneer based on quality and thickness.

- Identifying and removing defective pieces from the veneer sheets.

3. Maintaining Equipment

Veneer Sawyers are responsible for maintaining their saws and other equipment in good working condition. They perform regular inspections, clean and lubricate the machinery, and make minor repairs. They may also assist with major repairs or overhauls.

- Conducting regular maintenance and cleaning of veneer saws and related equipment.

- Troubleshooting and resolving minor equipment malfunctions.

4. Safety Compliance

Veneer Sawyers must adhere to strict safety regulations to prevent accidents. They wear protective gear, follow established safety procedures, and maintain a clean and organized work area. They also participate in safety training programs to stay up-to-date on best practices.

- Observing all safety protocols and procedures while operating veneer saws.

- Wearing appropriate personal protective equipment (PPE) such as safety glasses, earplugs, and gloves.

Interview Tips

To ace an interview for a Veneer Sawyer position, candidates should prepare thoroughly and demonstrate their skills and knowledge. Here are some tips to help candidates stand out during the interview:

1. Research the Company and Position

Before the interview, candidates should research the company they are applying to and the specific Veneer Sawyer position. This shows the interviewer that you are genuinely interested in the opportunity and have taken the time to understand the company’s values and goals.

- Visit the company’s website to learn about their products, services, and history.

- Read industry publications and articles to stay informed about the latest trends and technologies in the veneering industry.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the job requirements. Focus on your ability to operate veneer saws, maintain equipment, ensure veneer quality, and adhere to safety regulations.

- Quantify your accomplishments whenever possible using specific metrics and examples.

- Explain how your previous experience has prepared you for the challenges of the Veneer Sawyer role.

3. Demonstrate Safety Consciousness

Safety is paramount in the veneering industry. During the interview, emphasize your commitment to safety and demonstrate your knowledge of safety procedures and regulations. Explain how you prioritize safety in your work and take proactive measures to prevent accidents.

- Share examples of how you have followed safety regulations and prevented accidents in previous roles.

- Discuss your understanding of the Occupational Safety and Health Administration (OSHA) regulations and how you apply them in your work.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your interest in the company, the industry, or the specific role. This is also an opportunity to clarify any details and show that you are eager to learn and contribute.

- Ask about the company’s commitment to sustainability and environmental practices.

- Inquire about opportunities for professional development and training within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Veneer Sawyer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.