Are you gearing up for a career in Veneer Slicing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Veneer Slicing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

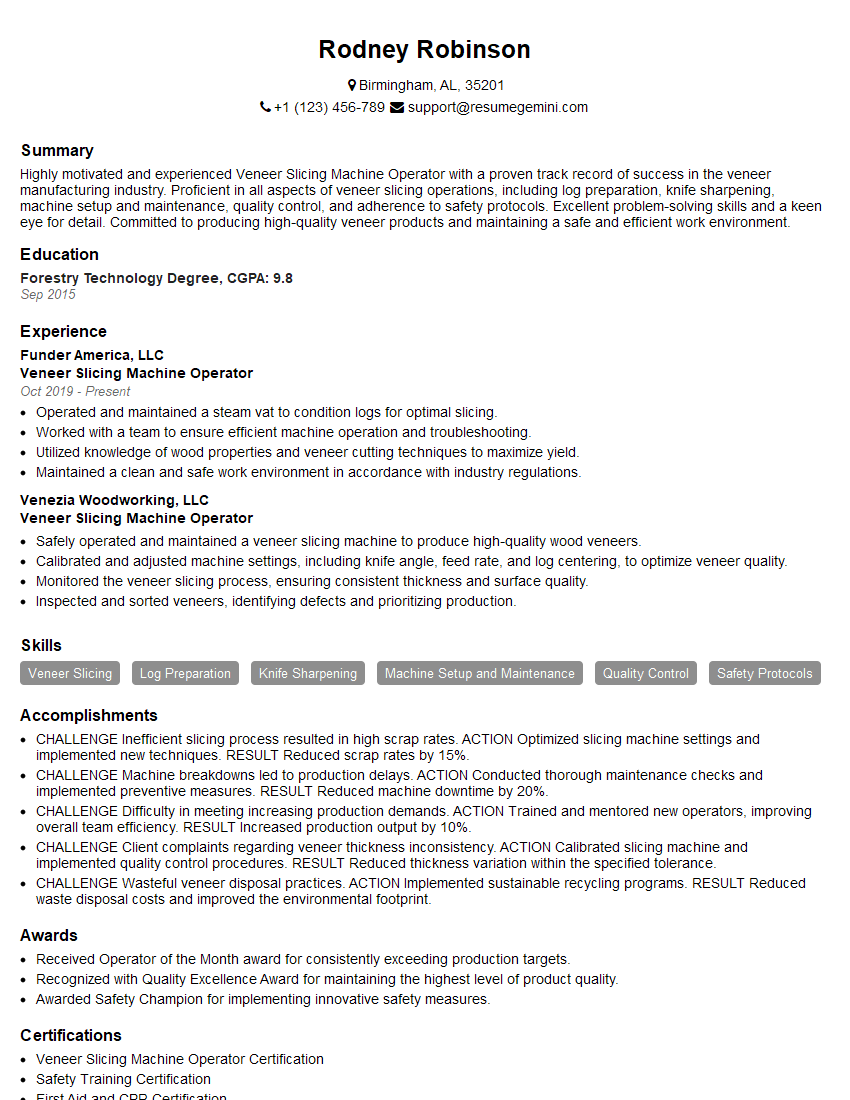

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Slicing Machine Operator

1. Describe the process of operating a veneer slicing machine.

The process of operating a veneer slicing machine involves several steps:

- Preparing the raw material: The wood log is first debarked and cut into suitable lengths. It is then soaked in water to soften it.

- Mounting the log: The log is mounted on a lathe and rotated against a sharp blade.

- Slicing the veneer: The blade slices a thin layer of wood off the log, creating a continuous sheet of veneer.

- Drying the veneer: The wet veneer is dried using a heated press or kiln to remove excess moisture.

- Grading and sorting: The dried veneer is graded according to its quality and appearance, and sorted into bundles.

2. What are the different types of veneer slicing machines?

Rotary Slicing Machines

- Used for slicing large logs into thin, continuous sheets of veneer.

- Blade is mounted on a rotating head and moves against the log.

Slicing Veneer Machines

- Used for slicing smaller logs or flitches.

- Blade is fixed and the log is moved against it.

Half-Round Slicing Machines

- Used for slicing logs that are not perfectly round.

- Blade follows the contour of the log, producing veneer with varying thicknesses.

3. How do you maintain a veneer slicing machine?

Maintaining a veneer slicing machine involves regular inspection, cleaning, and lubrication:

- Inspecting the blade: Regularly check the blade for sharpness and wear. Dull blades can produce uneven or torn veneer.

- Cleaning the machine: Remove wood chips and sawdust from the machine to prevent jamming and wear. Lubricating the machine: Apply lubricant to moving parts to reduce friction and ensure smooth operation.

- Checking the hydraulic system: Ensure that the hydraulic system is functioning properly and there are no leaks.

- Calibrating the machine: Regularly calibrate the machine to maintain accurate veneer thickness and width.

4. How do you troubleshoot common problems with a veneer slicing machine?

Common problems with veneer slicing machines and their troubleshooting steps:

- Uneven veneer thickness: Check the blade sharpness, machine calibration, and log preparation.

- Torn or chipped veneer: Check the blade sharpness, log preparation, and machine settings.

- Jamming: Remove wood chips and sawdust from the machine, check for any obstructions, and ensure proper lubrication.

- Hydraulic system failure: Check for leaks, inspect the hydraulic fluid level and pressure, and contact a technician if necessary.

5. What are the safety precautions to be followed when operating a veneer slicing machine?

Safety precautions for operating a veneer slicing machine include:

- Wear appropriate PPE: Wear safety glasses, gloves, and ear protection.

- Keep the work area clean: Remove loose materials and sawdust to prevent tripping or slipping.

- Be aware of moving parts: Keep hands away from rotating blades and moving machinery.

- Use proper lifting techniques: Avoid lifting heavy logs or veneer bundles manually. Use mechanical aids or assistance.

- Follow manufacturer’s instructions: Read and understand the operating manual for the specific machine being used.

6. How do you determine the optimal cutting angle for veneer slicing?

Determining the optimal cutting angle for veneer slicing depends on several factors:

- Wood species: Different wood species have different grain structures and require specific cutting angles.

- Veneer thickness: Thinner veneers require a smaller cutting angle to prevent tearing.

- Desired veneer quality: A smaller cutting angle produces a smoother veneer surface, while a larger angle may result in a rougher surface.

- Machine capabilities: The machine’s maximum cutting angle and the available blade options should be considered.

7. How do you handle defects in the veneer produced?

Defects in veneer can include knots, splits, and discoloration.

- Knots: Small knots can be trimmed or patched, while larger knots may require the veneer to be discarded.

- Splits: Minor splits can be repaired using adhesives, while severe splits may require the veneer to be rejected.

- Discoloration: Discolored areas can be bleached or stained to improve the appearance, or the affected parts can be cut away.

8. What are the different methods of drying veneer?

Natural Air Drying

- Veneer is stacked in layers and allowed to air dry gradually.

- Slow but sustainable method.

Kiln Drying

- Veneer is placed in a kiln and subjected to controlled temperature and humidity.

- Faster and more efficient method.

Vacuum Drying

- Veneer is placed in a vacuum chamber and heated while vacuum pressure removes moisture.

- Very fast but also expensive method.

9. How do you grade veneer?

Veneer is graded based on its appearance, quality, and suitability for different applications:

- Appearance grade: Assesses the presence of defects, such as knots, splits, and discolorations.

- Quality grade: Indicates the overall strength, durability, and stability of the veneer.

- Application grade: Specifies the intended use of the veneer, such as for furniture, flooring, or musical instruments.

10. What are the recent advancements in veneer slicing technology?

Recent advancements in veneer slicing technology include:

- Computerized Numerical Control (CNC) slicing: Allows for precise cutting and automation of the slicing process.

- Laser cutting: Uses a laser beam to slice veneer, resulting in smoother and more accurate cuts.

- 3D veneer slicing: Enables the production of veneer with varying thicknesses and textures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Slicing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Slicing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Veneer Slicing Machine Operators are responsible for operating and maintaining veneer slicing machines, which cut thin sheets of wood from logs. Their key responsibilities include:

1. Machine Operation

• Set up and operate veneer slicing machines according to specifications.

• Monitor machine operation and make adjustments as needed.

• Maintain and troubleshoot machines to ensure optimal performance.

2. Log Handling

• Inspect logs for quality and select appropriate logs for slicing.

• Load and unload logs onto the slicing machine.

• Remove sliced veneers from the machine and stack them for further processing.

3. Product Inspection and Quality Control

• Inspect sliced veneers for defects and ensure they meet quality standards.

• Sort and grade veneers based on thickness and quality.

• Keep records of production and quality control data.

4. Safety and Maintenance

• Wear appropriate safety gear and follow safety procedures.

• Perform routine maintenance and cleaning of machines and equipment.

• Report any safety hazards or maintenance issues to supervisors.

Interview Tips

To ace an interview for the position of Veneer Slicing Machine Operator, candidates should prepare thoroughly by following these tips:

1. Research the Company and the Role

• Gather information about the company’s history, products, and industry standing.

• Study the job description to understand the specific responsibilities and Anforderungen.

2. Practice Answering Common Interview Questions

• Prepare answers to questions about your experience in veneer slicing, machine operation, and quality control.

• Consider using the STAR method (Situation, Task, Action, Result) to provide detailed and specific examples of your skills.

3. Highlight Relevant Experience and Skills

• Emphasize your experience in operating veneer slicing machines or related equipment.

• Showcase your knowledge of machine maintenance, troubleshooting, and quality control procedures.

4. Demonstrate Safety Awareness

• Discuss your understanding of safety protocols in the workplace and your commitment to following them.

• Share examples of how you have ensured safety while operating machines or handling materials.

5. Prepare Questions for the Interviewers

• Asking thoughtful questions shows your interest in the role and the company.

• Consider questions about the company’s production processes, quality standards, and growth prospects.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Veneer Slicing Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Veneer Slicing Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.