Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Veneer Splicer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Veneer Splicer so you can tailor your answers to impress potential employers.

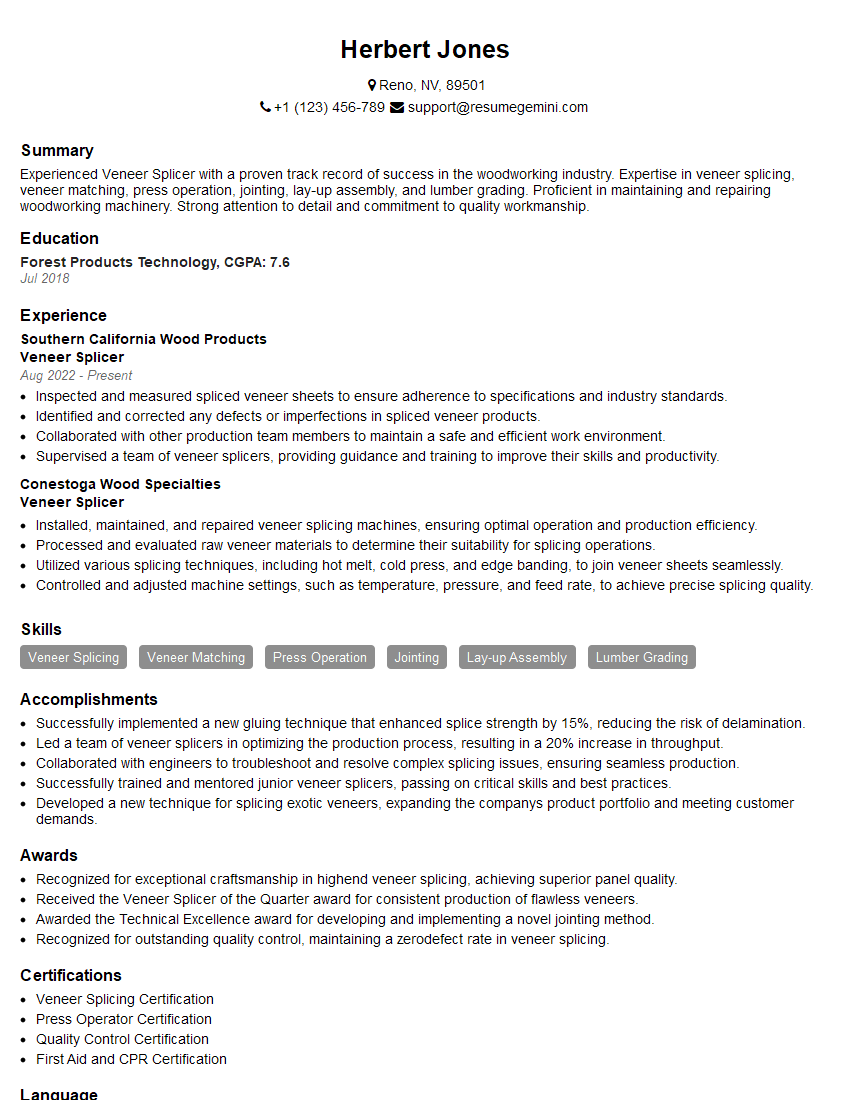

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Splicer

1. Describe the process of preparing veneer for splicing?

- Inspect the veneer for defects and cut away any damaged sections.

- Edge-joint the veneer pieces together to create a continuous sheet.

- Apply glue to the edges of the veneer and press them together to form a bond.

- Trim the excess glue and sand the spliced area to create a smooth surface.

2. What are the different types of veneer splicers?

- Butt splicers: These splicers join the edges of two pieces of veneer together without overlapping them.

- Edge-to-edge splicers: These splicers join the edges of two pieces of veneer together by overlapping them.

- V-splicers: These splicers join the edges of two pieces of veneer together by creating a V-shaped groove in one piece and a corresponding ridge in the other piece.

3. What are the factors that affect the strength of a veneer splice?

- The type of glue used: The strength of the glue will determine the strength of the splice.

- The thickness of the veneer: The thicker the veneer, the stronger the splice will be.

- The grain direction of the veneer: The splice will be stronger if the grain of the veneer is running perpendicular to the splice line.

- The temperature and humidity: The temperature and humidity will affect the curing time of the glue and the strength of the splice.

4. What are the common problems that can occur during veneer splicing?

- Gaps between the veneer pieces: This can be caused by improper preparation of the veneer, inadequate glue application, or insufficient pressure during clamping.

- Warping of the veneer: This can be caused by uneven moisture distribution in the veneer, improper clamping, or excessive heat during curing.

- Cracking of the veneer: This can be caused by excessive pressure during clamping, improper curing, or the use of brittle veneer.

5. What are the safety precautions that should be taken when working with veneer splicers?

- Wear appropriate protective gear: This includes safety glasses, gloves, and a dust mask.

- Keep the work area clean and free of debris: This will help to prevent accidents and ensure the proper functioning of the splicer.

- Follow the manufacturer’s instructions for operating the splicer: This will help to prevent accidents and ensure the proper functioning of the splicer.

6. What is the difference between a cold press and a hot press?

- Cold press: A cold press is a type of press that uses pressure to bond veneer without the use of heat.

- Hot press: A hot press is a type of press that uses heat and pressure to bond veneer.

7. What are the advantages and disadvantages of using a cold press?

Advantages

- Cold presses are less expensive than hot presses.

- Cold presses are easier to operate than hot presses.

- Cold presses can be used to bond a wider variety of materials than hot presses.

Disadvantages

- Cold presses require longer pressing times than hot presses.

- Cold presses can produce weaker bonds than hot presses.

8. What are the advantages and disadvantages of using a hot press?

Advantages

- Hot presses can produce stronger bonds than cold presses.

- Hot presses have shorter pressing times than cold presses.

Disadvantages

- Hot presses are more expensive than cold presses.

- Hot presses can be more difficult to operate than cold presses.

- Hot presses can only be used to bond materials that can withstand high temperatures.

9. What are the different types of glue that can be used for veneer splicing?

- Polyvinyl acetate (PVA) glue: This is a water-based glue that is commonly used for veneer splicing.

- Urea-formaldehyde (UF) glue: This is a water-based glue that is also commonly used for veneer splicing.

- Epoxy glue: This is a two-part glue that is very strong and durable.

10. What are the factors that should be considered when choosing a glue for veneer splicing?

- The type of veneer: The type of veneer will determine the strength and durability of the glue bond.

- The application: The application will determine the type of glue that is best suited for the job.

- The cost: The cost of the glue will also be a factor in the decision-making process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Splicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Splicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Veneer splicers play a crucial role in the production of high-quality veneer products by joining individual sheets of wood veneer together to form larger, continuous surfaces. Their responsibilities include:

1. Joining Veneer Sheets

Splicers are responsible for efficiently joining individual veneer sheets together, ensuring proper alignment and a seamless bond. They operate specialized splicing machines that apply heat, pressure, and glue to form a strong and durable joint.

2. Matching Color and Grain Patterns

Matching the color and grain patterns of adjacent veneer sheets is essential for creating visually appealing products. Splicers must possess a keen eye for detail and precision to ensure that the final veneer surface has a consistent and aesthetically pleasing appearance.

3. Ensuring Joint Strength and Quality

The strength and quality of the spliced joints are paramount to the overall integrity of the veneer product. Splicers must carefully monitor the bonding process and adjust machine settings as needed to ensure optimal joint strength and durability.

4. Operating and Maintaining Equipment

Splicers operate sophisticated veneer splicing machines that require regular maintenance and calibration. They must be proficient in troubleshooting and resolving any equipment malfunctions to maintain a smooth and efficient production process.

Interview Tips

Preparing thoroughly for an interview is essential to showcase your skills and make a positive impression. Here are some key tips to help you ace your interview for a veneer splicer position:

1. Research the Company and Role

Before the interview, take the time to research the company’s history, products, and industry reputation. Familiarize yourself with the specific responsibilities of the veneer splicer role and the company’s expectations. This knowledge will demonstrate your interest and preparation.

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview. Quantify your accomplishments whenever possible, using specific examples to demonstrate your proficiency in veneer splicing techniques, quality control measures, and equipment operation.

3. Practice Your Answers to Common Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your strengths and qualifications. Practice your responses aloud to ensure clarity and confidence during the interview.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive punctually for your interview. Maintain good posture, make eye contact, and be respectful to the interviewer.

5. Ask Informed Questions

At the end of the interview, ask informed questions to demonstrate your interest in the position and the company. This shows that you’re engaged and eager to learn more about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Veneer Splicer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!