Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Veneer Stock Layer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

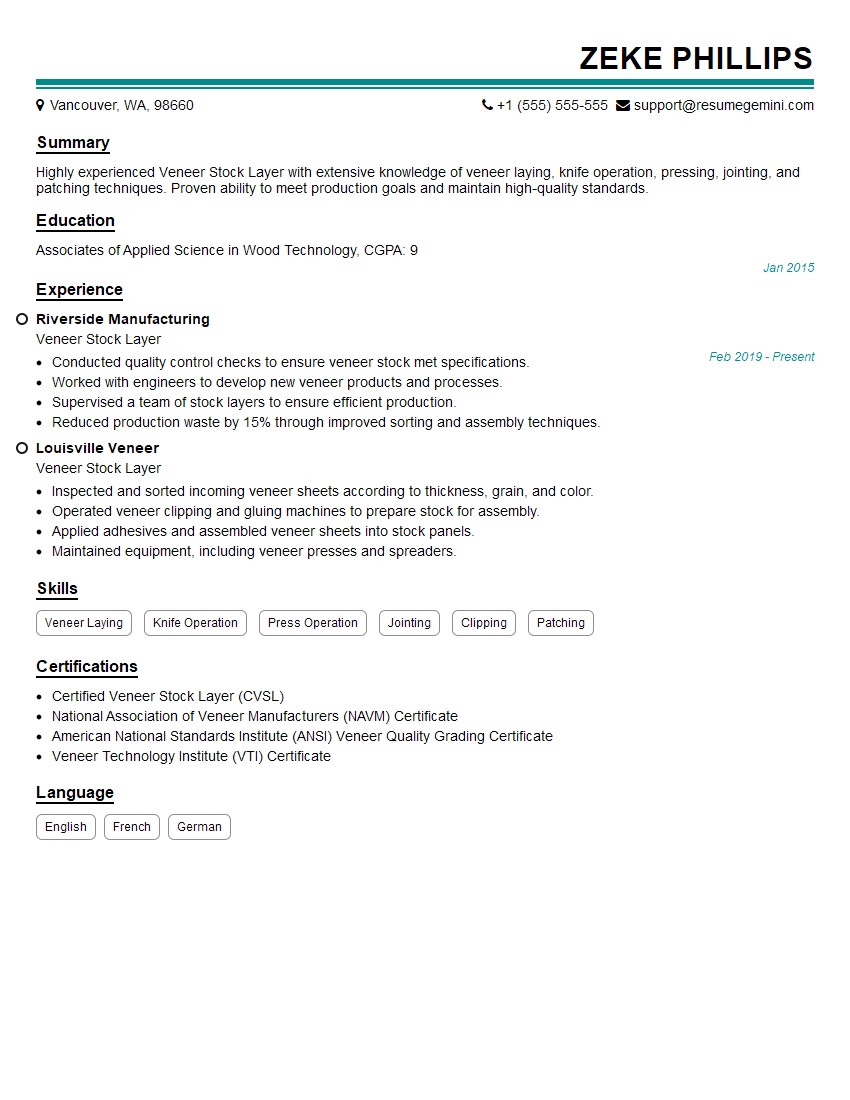

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Stock Layer

1. What are the different types of veneer stock layers?

Veneer stock layers can be classified based on the following types:

- Core Veneer: This is the thickest layer of veneer and forms the substrate of the plywood. It provides strength and stability to the panel.

- Crossband Veneer: This is a thin layer of veneer that is placed perpendicular to the core veneer. It helps to balance the stresses within the plywood and prevent warping.

- Face Veneer: This is the visible layer of veneer that determines the appearance of the plywood. It is typically made from high-quality wood species with attractive grain patterns.

2. What are the key qualities of a good veneer stock layer?

- Technical Knowledge: A good veneer stock layer must have a thorough understanding of veneer production processes, material properties, and industry standards.

- Attention to Detail: Veneer stock layers must be meticulous and pay close attention to detail to ensure that each layer is properly positioned and aligned.

- Problem-Solving Skills: Veneer stock layers may encounter unexpected challenges during the production process. They must be able to quickly identify and solve problems to maintain production efficiency.

- Communication Skills: Effective communication is essential for coordinating with other team members and ensuring that instructions are clearly understood.

- Physical Endurance: Veneer stock layers may need to lift heavy materials and work in physically demanding environments.

3. Describe the process of preparing veneer stock for layup.

- Material Selection: The veneer stock layer carefully selects veneer sheets based on species, thickness, and grain orientation to meet the desired specifications.

- Moisture Content Adjustment: The veneer sheets are conditioned to achieve the appropriate moisture content, typically between 6% and 8%, to ensure proper adhesion during layup.

- Sorting and Grading: The veneer sheets are sorted and graded based on quality and appearance to ensure that only the best pieces are used.

- Clipping and Trimming: The veneer sheets are clipped and trimmed to the correct size and shape to minimize waste and ensure a perfect fit during layup.

4. What are the different methods of veneer layup?

- Manual Layup: This method involves manually positioning and gluing each veneer sheet onto the core layer, requiring precision and skill.

- Mechanical Layup: This method uses a machine to automatically position and glue the veneer sheets, increasing efficiency and consistency.

- Vacuum Layup: This method uses a vacuum to remove air from between the veneer layers, creating a strong bond and preventing delamination.

5. How do you maintain the quality of veneer stock during layup?

- Proper Adhesion: Ensuring that the adhesive is evenly applied and that the veneer sheets are pressed with sufficient pressure to create a strong bond.

- Grain Matching: Matching the grain patterns of adjacent veneer sheets to enhance the aesthetic appearance and structural integrity of the plywood.

- Minimizing Waste: Optimizing the cutting and layup process to minimize waste and maximize material utilization.

- Quality Control: Regularly inspecting the veneer stock and layup process to identify and address any potential issues promptly.

6. What are the common defects that can occur during veneer stock layup?

- Delamination: The separation of veneer layers due to insufficient adhesive or improper bonding conditions.

- Voids: Air pockets trapped between veneer layers, weakening the bond and compromising the structural integrity.

- Grain Mismatch: Poor grain matching can lead to unsightly appearance and reduced strength.

- Edge Gaps: Gaps between veneer sheets at the edges, creating weak points and potential entry points for moisture.

7. How do you handle veneer stock with different species and thicknesses?

- Species Compatibility: Understanding the compatibility of different wood species and selecting adhesives that ensure proper bonding.

- Thickness Variation: Adjusting pressing and layup techniques to accommodate variations in veneer thickness, ensuring uniform bonding and structural integrity.

- Grain Orientation: Taking into account the grain orientation of each veneer sheet to optimize strength and aesthetic appeal.

- Moisture Adjustment: Adjusting the moisture content of different veneer species to achieve optimal bonding conditions and prevent warping.

8. What is the importance of veneer stock selection in producing high-quality plywood?

- Structural Stability: Choosing veneer stock with the appropriate strength and durability ensures the overall structural integrity of the plywood.

- Aesthetics: Veneer stock selection influences the appearance and grain patterns of the plywood, enhancing its visual appeal.

- Moisture Resistance: Selecting veneer stock with good moisture resistance properties helps prevent warping and delamination in humid environments.

- Cost Optimization: Careful veneer stock selection can optimize material utilization and reduce production costs without compromising quality.

9. Describe your experience in working with specialized veneer stock, such as figured or exotic veneers.

- Material Handling: Expertise in handling delicate and valuable figured or exotic veneers to prevent damage or defects.

- Grain Matching: Skilled in matching complex grain patterns to achieve visually stunning results.

- Adhesive Selection: Knowledge of specialized adhesives suitable for bonding exotic veneers and ensuring longevity.

- Finishing Techniques: Familiar with specialized finishing techniques to enhance the beauty and durability of exotic veneers.

10. How do you stay updated with the latest advancements in veneer stock layup technology and techniques?

- Industry Publications: Regularly reading trade magazines and journals to stay informed about new technologies and best practices.

- Conferences and Workshops: Attending industry conferences and workshops to learn about innovative techniques and advancements.

- Vendor Collaboration: Working closely with veneer suppliers and equipment manufacturers to gain insights into the latest developments.

- Continuous Learning: Demonstrating a commitment to continuous learning and professional development to stay ahead of the curve.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Stock Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Stock Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Veneer Stock Layers are responsible for handling and layering veneer for manufacturing wood-based products. Their primary duties include:

1. Veneer Handling and Preparation

• Unloading and handling incoming veneer rolls and sheets

• Inspecting veneer for defects and sorting it accordingly

• Preparing veneer by cutting, clipping, and splicing as required

2. Veneer Layering

• Laying up veneer sheets according to specified patterns and designs

• Using adhesives and other materials to bond veneer layers together

• Ensuring proper bonding by applying pressure and heat

3. Quality Control

• Inspecting finished veneers for quality and adherence to specifications

• Identifying and correcting defects in the layering process

• Maintaining records of veneer usage and quality control checks

4. Machine Operation and Maintenance

• Operating veneer saws, clippers, and other equipment for cutting and splicing veneer

• Cleaning and maintaining equipment to ensure optimal performance

Interview Tips

To excel in a Veneer Stock Layer interview, candidates should thoroughly prepare and demonstrate their knowledge and skills. Here are some tips:

1. Research the Company and Industry

• Learn about the company’s products, processes, and reputation

• Understand the current trends and advancements in the veneer industry

2. Highlight Relevant Experience and Skills

• Emphasize your experience in handling and layering veneer

• Showcase your knowledge of different veneer types, adhesives, and bonding techniques

• Mention any certifications or training related to veneer manufacturing

3. Practice Common Interview Questions

• Prepare for questions about your experience, qualifications, and motivations

• Practice answering questions related to veneer layering, quality control, and equipment operation

4. Prepare Questions for the Interviewer

• Asking thoughtful questions demonstrates your interest and engagement

• Inquire about the company’s specific veneer manufacturing processes or ask for insights into the industry

5. Emphasize Safety and Attention to Detail

• Highlight your commitment to safety in the workplace

• Demonstrate your attention to detail and ability to handle delicate materials

• Example Outline:

Answer: I am confident in my ability to excel as a Veneer Stock Layer at your company. Throughout my career, I have consistently exceeded expectations in handling and layering veneer. I possess a deep understanding of different veneer types, adhesives, and bonding techniques. I am also highly proficient in operating veneer saws, clippers, and other related equipment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Veneer Stock Layer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Veneer Stock Layer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.