Are you gearing up for a career in Veneer Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Veneer Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

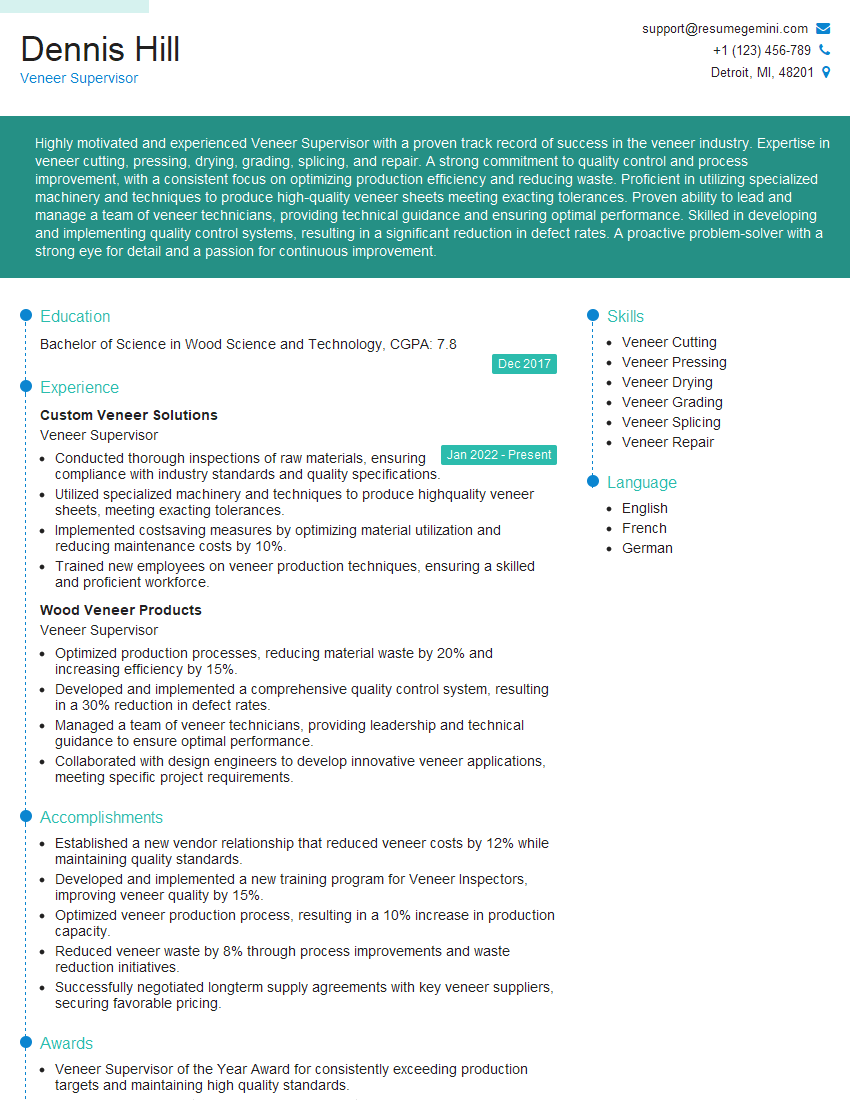

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Supervisor

1. What are the most important factors to consider when selecting veneer for a specific project?

When selecting veneer for a specific project, the most important factors to consider include:

- Species: Different species of wood have different colors, textures, and grain patterns. You need to select a species that will complement the overall design of the project.

- Grade: Veneer is graded based on its appearance. The grade you select will depend on the desired look of the project. For higher-quality projects, choose a higher grade of veneer.

- Thickness: Veneer is available in a range of thicknesses. The thickness you select will depend on where it will be used.

- Matching: If you are matching veneer to existing wood, be sure to consider the color, grain pattern, and finish of the existing wood.

2. What are the different types of veneer and how are they used?

Veneer Types:

- Rotary-cut veneer: This type of veneer is made by rotating a log against a blade. It is the most common type of veneer and is used in a wide variety of applications, including furniture, cabinetry, and flooring.

- Sliced veneer: This type of veneer is made by slicing a log into thin sheets. It is more expensive than rotary-cut veneer but produces a more consistent grain pattern.

- Half-round veneer: This type of veneer is made by cutting a log in half and then slicing it into thin sheets. It is more expensive than rotary-cut and sliced veneer but produces a unique and beautiful grain pattern.

Veneer Uses:

- Furniture: Veneer is used to create the surface of furniture, such as tables, chairs, and dressers.

- Cabinetry: Veneer is used to create the doors and drawers of cabinets.

- Flooring: Veneer is used to create the surface of flooring.

- Architectural millwork: Veneer is used to create architectural millwork, such as moldings, trim, and doors.

3. What are the different methods of applying veneer?

The different methods of applying veneer include:

- Hot press: This method uses a heated press to apply veneer to a substrate. This is the most common method of applying veneer.

- Cold press: This method uses a cold press to apply veneer to a substrate. This method is less common than hot pressing.

- Vacuum press: This method uses a vacuum press to apply veneer to a substrate. This method is used for large-scale applications.

- Contact cement: This method uses contact cement to apply veneer to a substrate. This method is used for small-scale applications.

- Iron-on: This method uses an iron to apply veneer to a substrate. This method is used for small-scale applications.

4. What are the different types of finishes that can be applied to veneer?

The different types of finishes that can be applied to veneer include:

- Clear finishes: These finishes allow the natural beauty of the veneer to show through.

- Tinted finishes: These finishes add a touch of color to the veneer.

- Pigmented finishes: These finishes completely cover the veneer with a new color.

- Textured finishes: These finishes add a textured effect to the veneer.

- Metallic finishes: These finishes give the veneer a metallic look.

5. What are the most common problems associated with veneer and how can they be prevented?

The most common problems associated with veneer include:

- Bubbling: This problem occurs when air becomes trapped between the veneer and the substrate. It can be prevented by using a vacuum press or by applying a release agent to the substrate.

- Wrinkling: This problem occurs when the veneer is not properly stretched before it is applied to the substrate. It can be prevented by using a tensioning device or by applying a heat gun to the veneer.

- Cracking: This problem occurs when the veneer is too thick or when it is not properly supported. It can be prevented by using a thinner veneer or by providing adequate support for the veneer.

- Peeling: This problem occurs when the adhesive between the veneer and the substrate fails. It can be prevented by using a high-quality adhesive and by applying it properly.

6. What are the latest trends in veneer applications?

The latest trends in veneer applications include:

- The use of exotic veneers: Exotic veneers are becoming increasingly popular due to their unique and beautiful grain patterns.

- The use of veneer in architectural applications: Veneer is being used in a variety of architectural applications, such as wall panels, ceilings, and doors.

- The use of veneer in furniture applications: Veneer is being used to create high-end furniture with a unique and luxurious look.

7. What are the most important qualities of a successful veneer supervisor?

The most important qualities of a successful veneer supervisor include:

- Technical knowledge: A veneer supervisor must have a thorough understanding of veneer and its applications.

- Experience: A veneer supervisor must have experience in the veneer industry.

- Leadership skills: A veneer supervisor must be able to lead and motivate a team of employees.

- Communication skills: A veneer supervisor must be able to communicate effectively with employees, customers, and suppliers.

- Problem-solving skills: A veneer supervisor must be able to solve problems quickly and efficiently.

8. What are the biggest challenges facing the veneer industry?

The biggest challenges facing the veneer industry include:

- The rising cost of raw materials: The cost of logs and other raw materials is rising, which is putting pressure on veneer manufacturers.

- The competition from other materials: Veneer is competing with other materials, such as laminates and plastics.

- The increasing demand for sustainable products: Consumers are increasingly demanding sustainable products, which is challenging veneer manufacturers to find ways to reduce their environmental impact.

- The shortage of skilled workers: The veneer industry is facing a shortage of skilled workers, which is making it difficult for veneer manufacturers to meet demand.

9. What are your strengths as a veneer supervisor?

My strengths as a veneer supervisor include:

- My technical knowledge: I have a thorough understanding of veneer and its applications.

- My experience: I have worked in the veneer industry for over 10 years.

- My leadership skills: I am a proven leader with a track record of success.

- My communication skills: I am an effective communicator with excellent interpersonal skills.

- My problem-solving skills: I am a quick and efficient problem solver.

10. What are your weaknesses as a veneer supervisor?

My weaknesses as a veneer supervisor include:

- My lack of experience in some areas: I do not have experience in all areas of veneer manufacturing.

- My temper: I am sometimes short-tempered when things do not go my way.

- My perfectionism: I am sometimes overly perfectionistic, which can lead to delays.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Veneer Supervisor is responsible for overseeing all aspects of veneer production and ensuring that the final product meets the required standards.

1. Production Planning and Scheduling

The Supervisor plans and schedules veneer production activities, including determining the sequence of operations, allocating resources, and establishing production targets.

- Develop and implement production plans to meet customer requirements and production targets.

- Schedule production activities, including machine setup, material handling, and employee assignments.

2. Quality Control

The Supervisor ensures that veneer products meet quality standards by monitoring production processes, inspecting finished products, and implementing corrective actions as needed.

- Develop and implement quality control procedures to ensure that veneer products meet specifications.

- Inspect finished veneer products to ensure compliance with quality standards.

3. Equipment Maintenance

The Supervisor maintains veneer production equipment to ensure optimal performance and prevent breakdowns.

- Conduct routine maintenance and repairs on veneer production equipment.

- Identify and resolve equipment issues to minimize downtime and maintain production efficiency.

4. Team Leadership and Development

The Supervisor leads and develops a team of veneer production workers, providing training, guidance, and support.

- Provide training and support to veneer production workers to ensure they have the necessary skills and knowledge.

- Monitor and evaluate employee performance to identify areas for improvement and development.

Interview Tips

To prepare for a Veneer Supervisor interview, it is important to thoroughly review the job description and research the company. Practice answering common interview questions and prepare questions to ask the interviewer.

1. Highlight Relevant Experience

Emphasize your experience in veneer production, quality control, and team leadership. Provide specific examples of your accomplishments and how they contributed to the success of your previous organization.

- Describe a time you successfully implemented a new quality control procedure that resulted in a significant reduction in product defects.

- Explain how you motivated and developed a team of veneer production workers to achieve consistently high levels of productivity.

2. Demonstrate Technical Knowledge

Demonstrate your knowledge of veneer production processes, equipment, and materials. Be prepared to discuss industry trends and best practices.

- Discuss the different types of veneer production methods and their advantages and disadvantages.

- Explain the importance of proper log selection and handling for veneer production.

3. Show Enthusiasm and Commitment

Convey your enthusiasm for the veneer industry and your commitment to producing high-quality products. Explain why you are interested in the position and how your skills and experience align with the company’s needs.

- Explain why you are passionate about veneer production and what drives your interest in the field.

- Describe your long-term career goals and how this position fits into your overall career aspirations.

4. Prepare Questions

Preparing questions to ask the interviewer demonstrates your interest in the position and the company. Ask questions about the company’s culture, growth plans, and opportunities for professional development.

- Ask about the company’s commitment to sustainability and environmental practices.

- Inquire about the company’s plans for investing in new technologies and equipment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Veneer Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.