Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Veneer Taper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

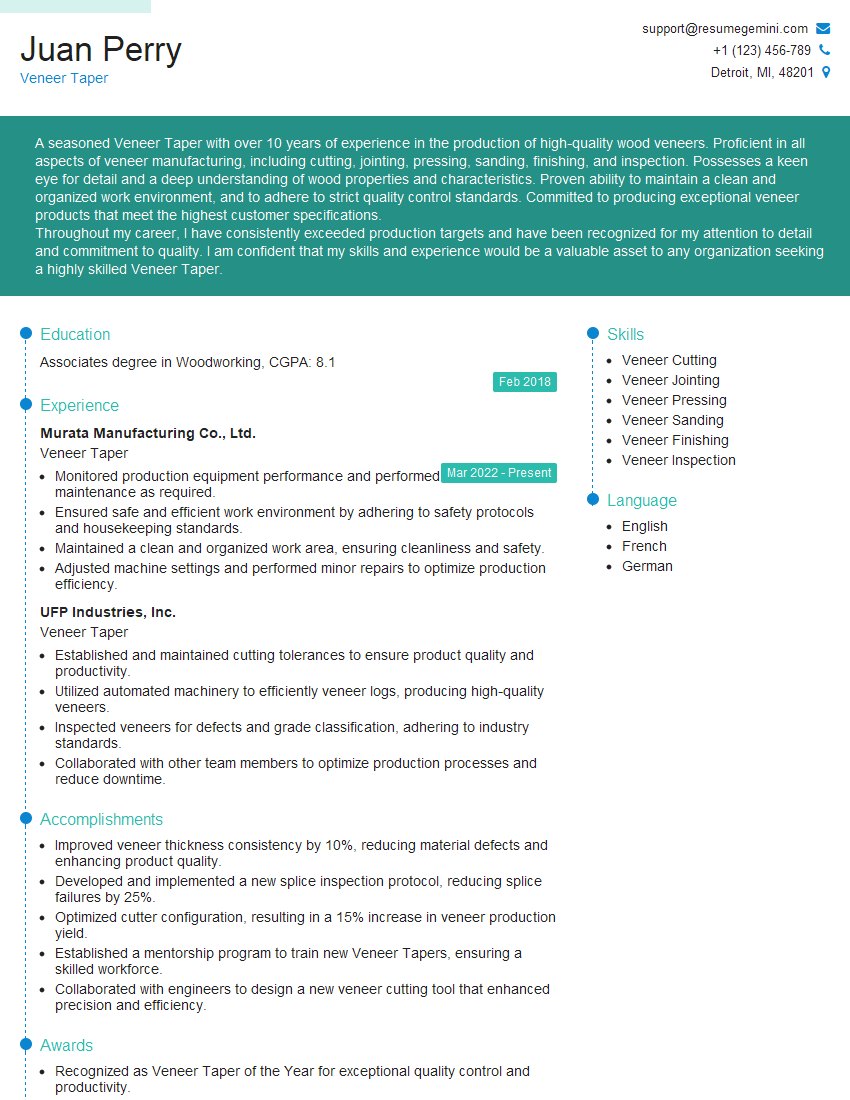

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Taper

1. How do you ensure that veneers are cut to the correct thickness consistently?

- Using precision cutting machines with computerized numerical control (CNC) systems.

- Regularly calibrating and maintaining the cutting equipment to ensure accuracy.

- Inspecting veneers before cutting to identify any defects or variations in thickness.

2. What techniques do you use to match and join veneers seamlessly?

Book matching

- Selecting veneers with similar grain patterns and arranging them like open pages of a book.

- Cutting veneers symmetrically to create a mirror-like effect when joined.

Slip matching

- Overlapping veneers slightly and aligning the grain patterns.

- Using a sharp blade to cut a thin sliver from the overlapping area, creating a concealed joint.

3. How do you handle veneer with varying moisture content?

- Assessing the moisture content of veneers before cutting and joining to prevent warping or shrinkage.

- Conditioning veneers to a specific moisture level by exposing them to controlled humidity or using a moisture meter.

- Using adhesives that are compatible with veneers of varying moisture content.

4. What quality control measures do you implement to ensure the production of high-quality veneered surfaces?

- Inspecting veneers before and after cutting to identify any defects or imperfections.

- Examining the finished veneered surfaces for any mismatches, gaps, or adhesive residues.

- Adhering to industry standards and quality specifications for veneer thickness, bond strength, and surface finish.

5. What are the different types of adhesives used in veneer taping and their advantages?

- Hot melt adhesives: Fast-setting, high-strength bonds, but can require specialized equipment.

- Cold press adhesives: Longer setting time, but provide stronger bonds over time.

- Contact adhesives: Instantaneous bonding, but require careful application to avoid air bubbles.

- Water-based adhesives: Environmentally friendly, but require longer press times.

6. How do you ensure the bond strength of veneer joints is durable and long-lasting?

- Preparing veneer surfaces properly by sanding or scraping to enhance adhesion.

- Applying adhesives evenly and following recommended pressure and temperature for optimal bonding.

- Allowing sufficient time for adhesives to cure completely before handling or exposing to stress.

- Testing bond strength regularly using industry-standard methods (e.g., ASTM D905).

7. What are some common challenges you face as a Veneer Taper and how do you overcome them?

- Veneer warpage: Using moisture control techniques, flattening veneers, and applying weights or clamps during pressing.

- Mismatched grain patterns: Careful veneer selection, book matching, and precise cutting to create seamless joins.

- Adhesive residue: Proper adhesive application, using cleaning agents, and allowing sufficient drying time.

- Tool maintenance: Regular sharpening and lubrication of cutting tools to ensure precision and efficiency.

8. How do you stay updated on the latest trends and techniques in veneer taping?

- Attending industry conferences and workshops.

- Reading trade publications and technical articles.

- Consulting with experts in the field.

- Participating in online forums and discussion groups.

9. What are the safety precautions that you take when working with veneers?

- Wearing appropriate personal protective equipment (PPE) such as gloves, dust masks, and safety glasses.

- Using sharp cutting tools carefully and following proper cutting techniques.

- Ensuring proper ventilation in the workspace to prevent exposure to dust and fumes.

- Handling veneers with care to avoid cuts or splinters.

10. How do you ensure that your work meets the specific requirements and specifications of clients?

- Communicating with clients to understand their needs and expectations.

- Reviewing project drawings and specifications thoroughly.

- Conducting thorough inspections and testing to ensure quality.

- Obtaining feedback from clients and making necessary adjustments to meet their satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Taper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Taper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Veneer tapers are responsible for operating and maintaining veneer tapering machines, which are used to cut veneer into specific shapes and sizes.

1. Machine Operation

They must be able to set up and operate the machine, and make adjustments as needed.

- Setting up and operating veneer tapering machines

- Making adjustments to the machine as needed

- Monitoring the machine’s operation and making sure it is running smoothly

2. Veneer Cutting

Veneer tapers must be able to cut veneer into specific shapes and sizes, according to the specifications of the customer.

- Cutting veneer into specific shapes and sizes

- Following the specifications of the customer

- Ensuring that the veneer is cut accurately and to the desired specifications

3. Quality Control

They must also inspect the veneer to make sure it meets the quality standards of the company.

- Inspecting veneer to make sure it meets the quality standards of the company

- Identifying and correcting any defects in the veneer

- Ensuring that the veneer is free of defects and meets the customer’s specifications

4. Maintenance

Veneer tapers must also perform basic maintenance on the veneer tapering machine.

- Performing basic maintenance on the veneer tapering machine

- Keeping the machine clean and in good working order

- Identifying and correcting any problems with the machine

Interview Tips to Ace the Veneer Taper Job

To ace the veneer taper job interview, it is important to be well-prepared and to highlight your relevant skills and experience.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and values.

- Read online reviews of the company to get a sense of the company culture.

- Research the specific position you are applying for to learn about the required skills and experience.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Write down a list of common interview questions.

- Practice your answers to these questions out loud.

- Get feedback from a friend or family member on your answers.

3. Highlight Your Relevant Skills and Experience

In your interview, be sure to highlight your relevant skills and experience. This includes your experience operating veneer tapering machines, your ability to cut veneer to precise specifications, and your knowledge of quality control procedures.

- Use specific examples to illustrate your skills and experience.

- Quantify your achievements whenever possible.

- Be prepared to discuss your experience in detail.

4. Be Enthusiastic and Positive

Finally, it is important to be enthusiastic and positive in your interview. This will show the interviewer that you are genuinely interested in the position and that you are confident in your abilities.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic about the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Veneer Taper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!