Are you gearing up for a career in Vertical Lathe Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Vertical Lathe Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

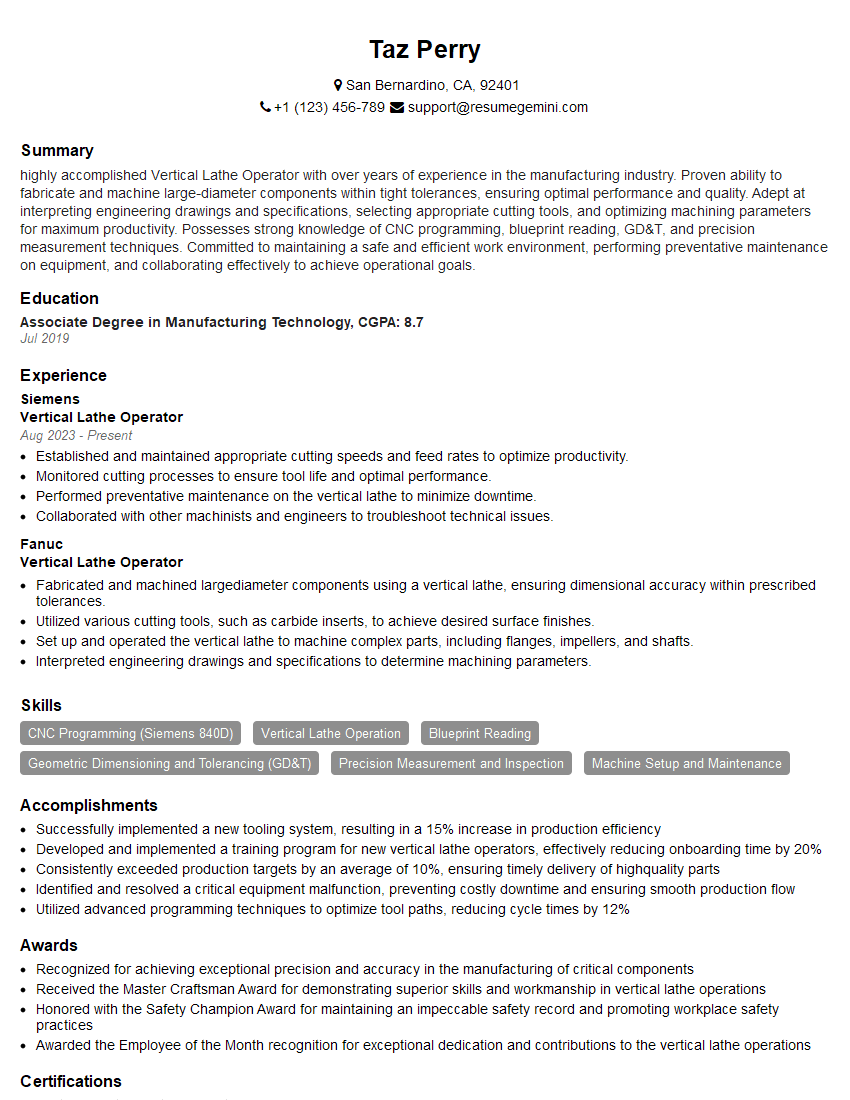

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vertical Lathe Operator

1. What are the safety precautions that must be observed when operating a vertical lathe?

- Always wear appropriate safety gear, including safety glasses, gloves, and a hard hat.

- Make sure the lathe is properly grounded and that all guards are in place.

- Never operate the lathe if you are tired or under the influence of drugs or alcohol.

- Be aware of the location of the emergency stop button and know how to use it.

- Keep the work area clean and free of debris.

2. What are the different types of tooling that can be used on a vertical lathe?

Turning tools

- Used to remove material from the workpiece.

- Come in a variety of shapes and sizes to accommodate different cutting operations.

Boring tools

- Used to create holes in the workpiece.

- Can be either solid or adjustable, and come in a variety of sizes.

Facing tools

- Used to create flat surfaces on the workpiece.

- Can be either single-point or multi-point, and come in a variety of sizes.

Knurling tools

- Used to create a textured surface on the workpiece.

- Come in a variety of patterns and sizes.

3. How do you set up a workpiece on a vertical lathe?

- First, the workpiece must be centered on the lathe table.

- Next, the workpiece must be clamped to the table using a chuck or faceplate.

- Finally, the tooling must be set up and adjusted to the correct cutting depth and speed.

4. What are the different cutting speeds and feeds that can be used on a vertical lathe?

- The cutting speed is the speed at which the cutting tool moves across the workpiece.

- The feed rate is the speed at which the workpiece moves past the cutting tool.

- The correct cutting speed and feed rate will depend on the material of the workpiece, the type of cutting tool being used, and the desired surface finish.

5. How do you troubleshoot a vertical lathe?

- If the lathe is not running properly, the first step is to check the power supply.

- Next, check the hydraulic system to make sure that there is no leaks or blockages.

- Finally, check the tooling to make sure that it is sharp and properly adjusted.

6. What are the different types of maintenance that must be performed on a vertical lathe?

- Daily maintenance includes cleaning the lathe, checking the oil level, and greasing the bearings.

- Weekly maintenance includes inspecting the belts and pulleys, and checking the hydraulic system for leaks.

- Monthly maintenance includes changing the oil and filter, and inspecting the electrical system.

7. What are the different types of materials that can be machined on a vertical lathe?

- Vertical lathes can be used to machine a variety of materials, including metals, plastics, and wood.

- The type of material being machined will determine the cutting speed, feed rate, and tooling that must be used.

8. What are the different types of finishes that can be achieved on a vertical lathe?

- The type of finish that can be achieved on a vertical lathe will depend on the cutting tool being used and the cutting speed and feed rate.

- A smooth finish can be achieved by using a sharp cutting tool and a slow cutting speed and feed rate.

- A rough finish can be achieved by using a dull cutting tool and a fast cutting speed and feed rate.

9. What are the different types of coolant systems that can be used on a vertical lathe?

- Flood coolant systems use a large volume of coolant to flood the cutting area.

- Mist coolant systems use a small amount of coolant to mist the cutting area.

- Air coolant systems use a stream of air to cool the cutting area.

10. What are the different types of programming systems that can be used to control a vertical lathe?

- Manual programming systems require the operator to manually enter the cutting data into the lathe’s control panel.

- Computer-aided programming (CAM) systems allow the operator to create a cutting program using a computer.

- Conversational programming systems allow the operator to enter the cutting data into the lathe’s control panel using a series of prompts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vertical Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vertical Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Vertical Lathe Operators play a crucial role in manufacturing industries, operating specialized machinery to produce complex and precise components. Their key responsibilities include:

1. Machine Operation

Expertise in operating vertical lathes, following blueprints and work orders to produce parts to specified dimensions and tolerances.

- Setting up the lathe, installing tooling and workpieces accurately

- Operating the lathe to perform various machining operations, such as turning, facing, boring, and threading

- Monitoring the lathe’s operation, adjusting parameters as needed, and ensuring the quality of the finished parts

2. Quality Assurance

Ensuring that the produced components meet the required specifications and quality standards.

- Performing quality checks using measuring instruments and gauges

- Identifying and correcting any deviations from the specifications

- Maintaining records of inspections and quality control procedures

3. Maintenance

Keeping the lathe and associated equipment in good working condition to prevent breakdowns and ensure optimal performance.

- Performing routine maintenance tasks, such as lubrication, cleaning, and adjustments

- Identifying and troubleshooting any mechanical or electrical problems

- Reporting any maintenance issues to the supervisor promptly

4. Safety Procedures

Adhering to all safety regulations and guidelines while operating the lathe and handling materials.

- Wearing appropriate safety gear, such as gloves, eye protection, and earplugs

- Following lockout/tagout procedures when performing maintenance

- Maintaining a clean and organized work area

Interview Tips

To ace the interview for a Vertical Lathe Operator position, candidates should keep the following tips in mind:

1. Research the Company and the Role

Gather information about the company’s products, services, and industry to show that you have genuine interest in the position and understand the company’s needs.

- Review the company’s website, social media pages, and industry news

- Learn about the specific role and its requirements

- Prepare questions to ask the interviewer about the company and the position

2. Highlight Your Skills and Experience

Emphasize your technical skills and experience that are relevant to the role. Provide specific examples to demonstrate your abilities.

- Highlight your expertise in operating vertical lathes and your knowledge of different machining processes

- Share examples of complex parts you have produced and the techniques you used to achieve precision

- Describe your experience in quality control and troubleshooting

3. Demonstrate Your Safety Consciousness

Emphasize your commitment to safety and your understanding of safety protocols in a manufacturing environment.

- Describe your experience in following safety regulations and procedures

- Share an example of how you identified a potential hazard and implemented corrective measures

- Explain your understanding of lockout/tagout procedures and other safety best practices

4. Prepare for Common Interview Questions

Research common interview questions for Vertical Lathe Operators and prepare thoughtful answers.

- Why are you interested in this role?

- What are your strengths and weaknesses as a Vertical Lathe Operator?

- Describe your experience in operating vertical lathes and producing precision parts

- How do you ensure the quality of your work?

- What is your approach to safety in the workplace?

5. Be Enthusiastic and Professional

Show your enthusiasm for the role and the manufacturing industry. Dress professionally and maintain a positive attitude throughout the interview.

- Be confident and articulate your answers clearly

- Be prepared to ask questions about the company and the position

- Thank the interviewer for their time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Vertical Lathe Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.