Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Vertical Multiple Spindle Chucking Machine Set-Up Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Vertical Multiple Spindle Chucking Machine Set-Up Operator so you can tailor your answers to impress potential employers.

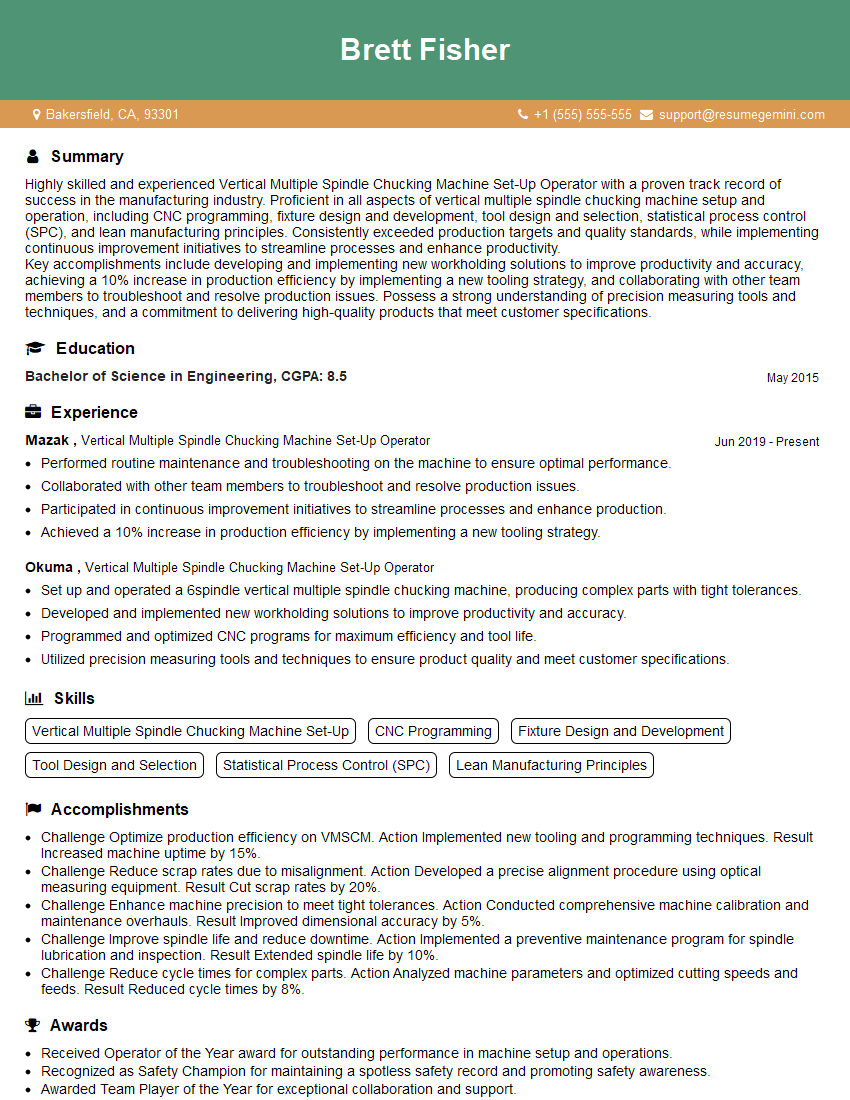

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vertical Multiple Spindle Chucking Machine Set-Up Operator

1. Describe the process of setting up a vertical multiple spindle chucking machine?

- Prepare the machine by cleaning and lubricating it.

- Install the workpiece and secure it in the chuck.

- Mount the appropriate cutting tools and set the spindle speeds and feeds.

- Program the machine’s CNC controller with the required machining operations.

- Inspect the setup to ensure accuracy and safety.

2. Explain how to align and adjust the spindles on a vertical multiple spindle chucking machine?

Spindle alignment:

- Use a dial indicator to check the concentricity of the spindles.

- Adjust the spindle bearings and mountings as necessary to achieve the desired alignment.

Spindle adjustment:

- Set the spindle speeds and feeds to the appropriate values for the machining operation.

- Use a torque wrench to tighten the spindle nuts to the specified torque.

3. What are the different types of cutting tools used on a vertical multiple spindle chucking machine?

- Boring tools

- Turning tools

- Drilling tools

- Reaming tools

- Tapping tools

4. How do you select the appropriate cutting tools for a specific machining operation?

- Consider the material being machined.

- Determine the required cutting speed and feed rate.

- Choose a tool with the appropriate geometry and sharpness.

- Ensure that the tool is properly mounted and secured.

5. Describe the safety precautions that must be observed when operating a vertical multiple spindle chucking machine?

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Ensure that the machine is properly grounded.

- Keep the work area clean and free of debris.

- Never operate the machine with the guards removed.

- Follow all manufacturer’s instructions for safe operation.

6. How do you troubleshoot common problems that may occur during the operation of a vertical multiple spindle chucking machine?

- Spindle vibration: check spindle bearings and alignment.

- Tool breakage: check tool sharpness, mounting, and cutting parameters.

- Surface finish problems: check tool sharpness, cutting parameters, and workpiece material.

- Dimensional accuracy problems: check machine calibration, tool alignment, and workpiece setup.

7. What maintenance procedures are required for a vertical multiple spindle chucking machine?

- Regular cleaning and lubrication.

- Spindle bearing inspection and adjustment.

- Toolholder inspection and tightening.

- Hydraulic and pneumatic system maintenance.

- Electrical system inspection and repair.

8. How do you maintain the accuracy and precision of a vertical multiple spindle chucking machine?

- Regularly calibrate the machine according to manufacturer’s instructions.

- Inspect and adjust the spindles and toolholders for alignment and accuracy.

- Use high-quality cutting tools and maintain them properly.

- Follow recommended cutting parameters and machining practices.

9. What experience do you have with programming and operating CNC machines?

- Experience with CNC programming software, such as Mastercam or Siemens NX.

- Knowledge of G-code and M-code programming.

- Experience with setting up and operating CNC machines, including vertical multiple spindle chucking machines.

10. What are your strengths and weaknesses as a vertical multiple spindle chucking machine set-up operator?

Strengths:

- Strong technical skills and knowledge of vertical multiple spindle chucking machines.

- Excellent attention to detail and ability to follow instructions precisely.

- Proven ability to troubleshoot and resolve machine problems quickly and efficiently.

Weaknesses:

- Limited experience with some of the latest CNC programming software.

- Working independently for extended periods of time can be challenging.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vertical Multiple Spindle Chucking Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vertical Multiple Spindle Chucking Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Vertical Multiple Spindle Chucking Machine Set-Up Operators play a fundamental role in manufacturing industries, responsible for ensuring the efficient and accurate preparation and operation of vertical multiple spindle chucking machines. Their key responsibilities include:

1. Set-Up and Maintenance

They are responsible for setting up and configuring the machine according to production requirements. This involves installing and aligning tools, workpieces, and fixtures, as well as adjusting machine parameters to optimize performance. They also perform regular maintenance tasks, including cleaning, lubrication, and troubleshooting to maintain the machine in good working condition.

2. Planning and Organization

These operators plan and organize their work to maximize efficiency and minimize downtime. They review blueprints and production schedules to determine the sequence of operations, select the appropriate tooling, and ensure that all necessary materials are available. They also coordinate with other team members, such as machinists and engineers, to ensure smooth production flow.

3. Quality Control

Maintaining product quality is crucial for these operators. They inspect raw materials and finished products to ensure they meet specifications. They monitor machine performance and make adjustments as necessary to maintain accuracy and prevent defects. They also maintain records of production data, quality checks, and machine maintenance for future reference.

4. Safety Compliance

Safety is paramount in any manufacturing environment. These operators adhere to all safety regulations and guidelines. They wear appropriate personal protective equipment, follow proper operating procedures, and maintain a clean and organized work area to prevent accidents and injuries.

Interview Tips

Preparing for an interview for the position of Vertical Multiple Spindle Chucking Machine Set-Up Operator requires a strategic approach. Here are some interview preparation tips to help you ace the interview:

1. Research the Company and Position

Gather information about the company and the specific role you are applying for. Understanding the company’s products, services, values, and industry standing will demonstrate your interest and enthusiasm. Review the job description carefully to identify the essential skills and responsibilities required for the position.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to showcase your relevant skills and experience. Quantify your accomplishments whenever possible, using specific metrics and data to demonstrate your contributions. Use keywords from the job description in your application materials to match the employer’s requirements.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. These may include questions about your technical expertise, experience with specific machines or processes, and your understanding of industry standards. Research industry trends and developments to demonstrate your knowledge and stay ahead of the competition.

4. Prepare Questions for the Interviewers

Preparing thoughtful questions for the interviewers shows your engagement and interest in the role. Questions about the company’s culture, growth plans, or technological advancements demonstrate your curiosity and desire to align with their vision. Avoid asking generic questions that can be easily found on the company website.

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally for the interview and arrive on time or slightly early. Your appearance and punctuality convey respect for the interviewer and demonstrate your commitment to the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Vertical Multiple Spindle Chucking Machine Set-Up Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.