Feeling lost in a sea of interview questions? Landed that dream interview for Vertical Punch Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Vertical Punch Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

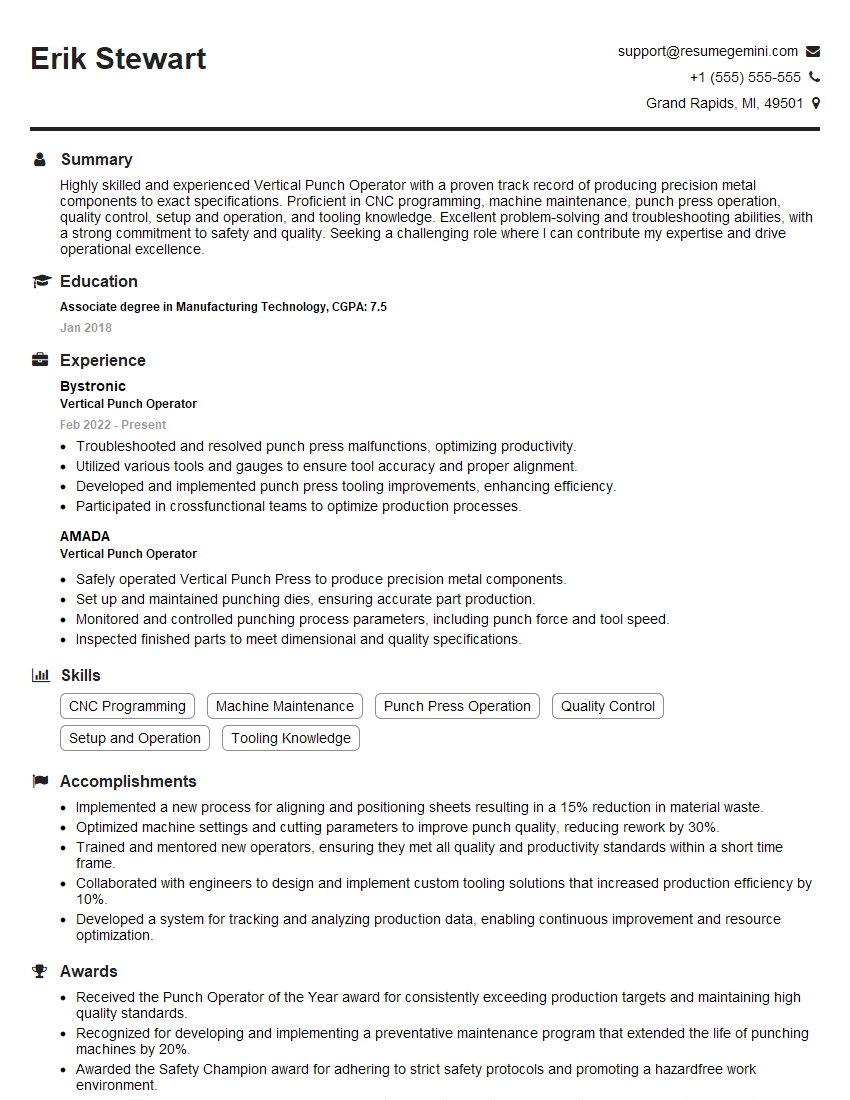

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vertical Punch Operator

1. What are the key responsibilities of a Vertical Punch Operator?

As a Vertical Punch Operator, my primary responsibilities include:

- Operating and maintaining a vertical punch press to cut and form metal components.

- Interpreting technical drawings and work orders to determine the correct setup and operation of the machine.

- Ensuring the accuracy and quality of punched parts by regularly inspecting and adjusting the machine.

- Monitoring the machine during operation to identify and address any potential issues or malfunctions.

- Performing regular maintenance and cleaning tasks to keep the machine running smoothly.

2. How do you determine the correct tonnage and speed settings for a punch press?

Factors Considered:

- Thickness and hardness of the metal being punched.

- Size and shape of the hole or punch to be made.

- Type of punch and die used.

- Desired production rate.

Process:

- Consult technical specifications and experience to select appropriate tonnage and speed settings.

- Start with conservative settings and gradually increase or decrease as needed to achieve optimal results.

- Monitor the machine during operation and make adjustments to ensure the punch press is operating efficiently.

3. What are some common troubleshooting techniques for a vertical punch press?

In the event of any issues with the vertical punch press, I employ the following troubleshooting techniques:

- Electrical Problems: Verify power supply, check for loose connections, inspect wiring for damage.

- Mechanical Issues: Lubricate moving parts, adjust clearances, inspect for wear and tear on critical components.

- Tooling Malfunctions: Inspect punch and die for wear or damage, ensure proper alignment, check for any obstructions.

- Material Handling Problems: Verify correct material thickness and alignment, adjust feed rate if necessary.

- Operator Error: Review work orders and technical drawings for accuracy, ensure proper setup and operation of the machine.

4. How do you ensure safety when operating a vertical punch press?

Safety is paramount when working with a vertical punch press, and I adhere to the following measures:

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Inspect the machine thoroughly before each use, ensuring guards and safety features are functioning properly.

- Maintain a clean and organized work area, removing any potential tripping or slipping hazards.

- Follow proper lockout/tagout procedures when performing maintenance or repairs.

- Never operate the machine under the influence of drugs or alcohol.

5. What types of maintenance tasks are typically required for a vertical punch press?

To ensure optimal performance and longevity of the vertical punch press, I regularly perform the following maintenance tasks:

- Daily: Lubricate moving parts, clean the machine, inspect for any signs of wear or damage.

- Weekly: Check and adjust clearances, inspect punches and dies for wear, tighten loose bolts or connections.

- Monthly: Perform a thorough inspection of the machine, replace worn components, calibrate sensors.

- Quarterly: Conduct a comprehensive maintenance overhaul, including electrical and mechanical checks, lubrication of all critical components.

6. How do you handle variations in material thickness when using a vertical punch press?

To accommodate variations in material thickness, I take the following steps:

- Verify material thickness: Measure the material using a micrometer or other precision measuring tool.

- Adjust press settings: Based on the measured thickness, I recalculate the required tonnage and speed settings.

- Test and adjust: Perform a test punch to ensure the new settings produce the desired results. Continue to adjust until optimal quality is achieved.

7. What are the different types of punches used in a vertical punch press?

Vertical punch presses utilize various types of punches, each designed for specific applications:

- Standard round punches: For general-purpose punching of holes in various sizes and materials.

- Oblong punches: Used to create elongated or rectangular holes.

- Square or rectangular punches: For punching square or rectangular shapes with precise dimensions.

- Form punches: Used to create complex shapes, bends, or embossments in metal.

- Special-purpose punches: Designed for specific industry applications, such as louvering, slotting, or dimpling.

8. How do you ensure the accuracy and precision of punched parts?

To achieve accurate and precise punched parts, I employ the following techniques:

- Proper setup: Carefully align the workpiece, punch, and die to ensure correct positioning.

- Sharp tooling: Use sharp punches and dies to minimize burrs and ensure clean cuts.

- Precision measuring tools: Utilize micrometers, calipers, or other precision measuring tools to verify the dimensions of the punched parts.

- Regular maintenance: Perform regular maintenance on the punch press to maintain its accuracy and precision.

9. Describe the process for setting up and operating a vertical punch press.

Setup:

- Mount the appropriate punch and die on the press.

- Adjust the press settings (tonnage, speed, stroke length) based on material thickness and punch size.

- Align the workpiece properly on the worktable.

Operation:

- Engage the safety mechanisms.

- Start the press and allow the punch to descend and form the hole or shape in the workpiece.

- Eject the punched part from the press.

10. How do you communicate any issues or concerns regarding the vertical punch press to your supervisor?

When encountering any issues or concerns with the vertical punch press, I follow these steps:

- Assessment: Identify the issue or concern clearly and gather relevant information.

- Notification: Inform my supervisor promptly, providing a detailed explanation of the situation.

- Collaboration: Work together with my supervisor to determine the root cause and develop a solution.

- Resolution: Implement the agreed-upon solution and follow up to ensure the issue is resolved.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vertical Punch Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vertical Punch Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Vertical Punch Operator is responsible for operating a vertical punch press to produce metal parts. The primary duties involve setting up and operating the machine, monitoring its performance, and ensuring the quality of the produced parts.

1. Machine Setup and Operation

Sets up and operates the vertical punch press according to specifications.

- Loads and unloads metal sheets into the machine.

- Selects and installs the appropriate dies and tooling.

- Adjusts machine settings for speed, pressure, and stroke length.

2. Quality Control

Inspects the produced parts for defects and ensures they meet quality standards.

- Conducts visual inspections.

- Uses measuring tools to verify dimensions and tolerances.

- Rejects or repairs defective parts.

3. Machine Maintenance

Performs basic maintenance and troubleshooting on the vertical punch press.

- Lubricates moving parts.

- Replaces worn or damaged dies and tooling.

- Reports any machine malfunctions to the supervisor.

4. Production Monitoring

Monitors the production process to ensure efficiency and productivity.

- Tracks production rates and identifies bottlenecks.

- Adjusts machine settings as needed.

- Reports production data to the supervisor.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips and hacks to help you ace the interview for a Vertical Punch Operator position:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific role you are applying for. This will help you understand the company’s culture, values, and the expectations for the position.

- Visit the company’s website to learn about their products, services, and recent news.

- Review the job description carefully to identify the key responsibilities and qualifications.

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked across industries. By practicing your answers to these questions, you can become more confident and articulate during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Highlight Your Relevant Skills and Experience

When answering interview questions, focus on highlighting your skills and experience that are most relevant to the job requirements. Use specific examples to demonstrate your abilities.

- Emphasize your experience operating vertical punch presses or similar machines.

- Showcase your knowledge of quality control processes and inspection techniques.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your curiosity and understanding of the role.

- What are the company’s goals for this position in the next year?

- What opportunities are there for professional development and growth?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Vertical Punch Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!