Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Vessel Slagman position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

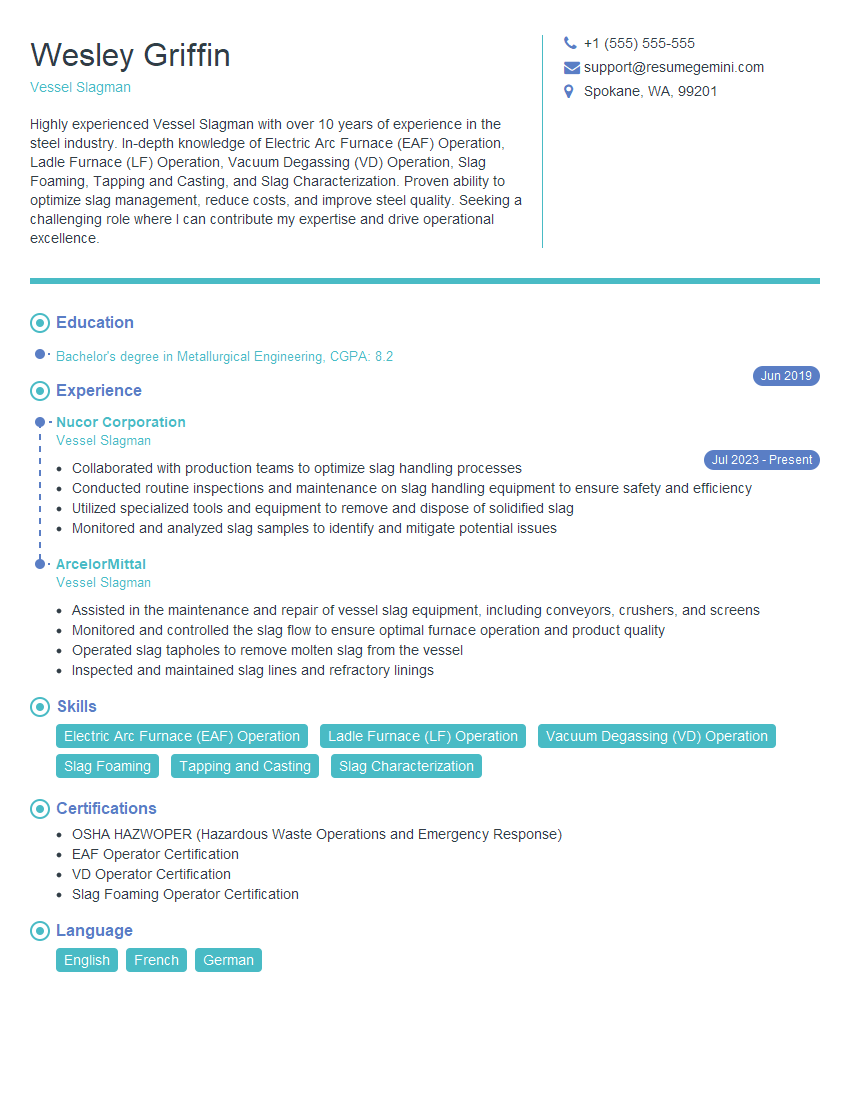

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vessel Slagman

1. What is the role of a Vessel Slagman?

The Vessel Slagman is responsible for the safe and efficient operation of the vessel’s slag handling system, ensuring compliance with all applicable environmental, safety, and operational regulations.

2. Describe the slag handling system on a vessel?

Slag Collection

- Molten slag is generated during the steelmaking process.

- It is tapped from the furnace into a slag pot.

Slag Transportation

- The slag pot is transported to the slag handling area.

- It is lifted and poured into a slag runner.

Slag Granulation

- The slag runner discharges the molten slag into a granulating tank.

- High-pressure water jets quench and solidify the slag into granules.

Slag Dewatering

- The slag granules are dewatered using a centrifuge or filter press.

Slag Disposal

- The dewatered slag is disposed of in a landfill or used as a construction material.

3. What are the key safety hazards associated with slag handling?

The key safety hazards associated with slag handling include:

- Extreme heat: Molten slag temperatures can exceed 1,500 degrees Celsius.

- Gases and fumes: Slag handling can release toxic gases and fumes, including sulfur dioxide and carbon monoxide.

- Burns: Contact with molten slag or slag granules can cause severe burns.

- Explosions: Water can react violently with molten slag, causing explosions.

4. What are the environmental regulations that apply to slag handling?

The environmental regulations that apply to slag handling include:

- Air pollution control: Slag handling systems must be equipped with air pollution control devices to reduce emissions of toxic gases and fumes.

- Water pollution control: Slag handling systems must be designed to prevent the discharge of contaminated water into the environment.

- Waste management: Slag must be disposed of in a manner that complies with all applicable environmental regulations.

5. What are the operational procedures for slag handling?

The operational procedures for slag handling include:

- Slag collection: Molten slag is tapped from the furnace into a slag pot.

- Slag transportation: The slag pot is transported to the slag handling area.

- Slag granulation: The molten slag is poured into a slag runner and quenched with high-pressure water jets.

- Slag dewatering: The slag granules are dewatered using a centrifuge or filter press.

- Slag disposal: The dewatered slag is disposed of in a landfill or used as a construction material.

6. What are the maintenance procedures for slag handling equipment?

The maintenance procedures for slag handling equipment include:

- Daily inspections: The equipment is inspected daily for any signs of damage or wear.

- Weekly maintenance: The equipment is cleaned and lubricated weekly.

- Monthly maintenance: The equipment is inspected and serviced monthly.

- Annual maintenance: The equipment is overhauled annually.

7. What are the troubleshooting procedures for slag handling problems?

The troubleshooting procedures for slag handling problems include:

- Clogged slag runner: If the slag runner becomes clogged, it can be cleared using a high-pressure water jet.

- Broken slag granulator: If the slag granulator breaks down, it can be repaired or replaced.

- Leaking slag pot: If the slag pot develops a leak, it can be repaired or replaced.

- Excessive slag dust: If the slag handling system is generating excessive slag dust, it can be controlled using air pollution control devices.

8. What are the quality control procedures for slag handling?

The quality control procedures for slag handling include:

- Slag sampling: Slag samples are collected and analyzed to ensure that they meet the required specifications.

- Slag testing: Slag samples are tested to determine their chemical composition, physical properties, and environmental impact.

- Slag disposal: Slag is disposed of in a manner that complies with all applicable environmental regulations.

9. What are the training requirements for Vessel Slagmen?

Vessel Slagmen must be trained in the following areas:

- Slag handling safety: Vessel Slagmen must be trained in the safe operation of slag handling equipment and procedures.

- Environmental regulations: Vessel Slagmen must be trained in the environmental regulations that apply to slag handling.

- Operational procedures: Vessel Slagmen must be trained in the operational procedures for slag handling.

- Maintenance procedures: Vessel Slagmen must be trained in the maintenance procedures for slag handling equipment.

- Troubleshooting procedures: Vessel Slagmen must be trained in the troubleshooting procedures for slag handling problems.

10. What are the career advancement opportunities for Vessel Slagmen?

Vessel Slagmen with experience and training can advance to the following positions:

- Slag handling supervisor: The slag handling supervisor is responsible for the overall operation of the slag handling system.

- Environmental compliance officer: The environmental compliance officer is responsible for ensuring that the slag handling system complies with all applicable environmental regulations.

- Operations manager: The operations manager is responsible for the overall operation of the vessel.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vessel Slagman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vessel Slagman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Vessel Slagman is an essential member of any steel production team, responsible for ensuring the smooth operation of the steelmaking process. The key job responsibilities of a Vessel Slagman include:

1. Slag Management

Vessel Slagmen are responsible for managing the slag, a waste product of the steelmaking process. They must ensure that the slag is properly disposed of and does not interfere with the production process.

- Operate slag pots and transfer slag from steelmaking vessels to slag disposal areas.

- Control slag chemistry to meet specifications and ensure proper functioning of the steelmaking process.

2. Vessel Operation

Vessel Slagmen also assist in the operation of steelmaking vessels. They must be familiar with the operation of these vessels and be able to identify and troubleshoot any problems.

- Assist in the charging of raw materials into steelmaking vessels.

- Monitor and adjust vessel conditions, such as temperature and oxygen levels, to optimize steel production.

3. Safety and Compliance

Vessel Slagmen must adhere to all safety regulations and procedures. They must also be aware of the environmental regulations that apply to their work.

- Follow safety protocols to prevent accidents and injuries.

- Comply with environmental regulations related to slag disposal and waste management.

4. Teamwork and Communication

Vessel Slagmen work as part of a team, and they must be able to communicate effectively with other team members. They must also be able to follow instructions and work independently.

- Collaborate with other team members to ensure the smooth operation of the steelmaking process.

- Communicate effectively with supervisors, operators, and other personnel to exchange information and coordinate activities.

Interview Tips

To ace an interview for a Vessel Slagman position, it is important to be prepared and show the interviewer that you have the necessary skills and experience. Here are a few tips to help you prepare for your interview:

1. Research the Company and the Position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can research the company on their website, Glassdoor, or other online resources.

2. Practice Your Answers

Once you have researched the company and the position, you should practice your answers to common interview questions. This will help you feel more confident and prepared during your interview. Some common interview questions that you may be asked include:

- Tell me about your experience with slag management.

- How do you ensure the safe and efficient operation of steelmaking vessels?

- Describe your teamwork and communication skills.

3. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic and positive about their work. During your interview, be sure to show the interviewer that you are passionate about the steel industry and that you are eager to learn and grow.

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Vessel Slagman interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!