Are you gearing up for a career in Vinegar Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Vinegar Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

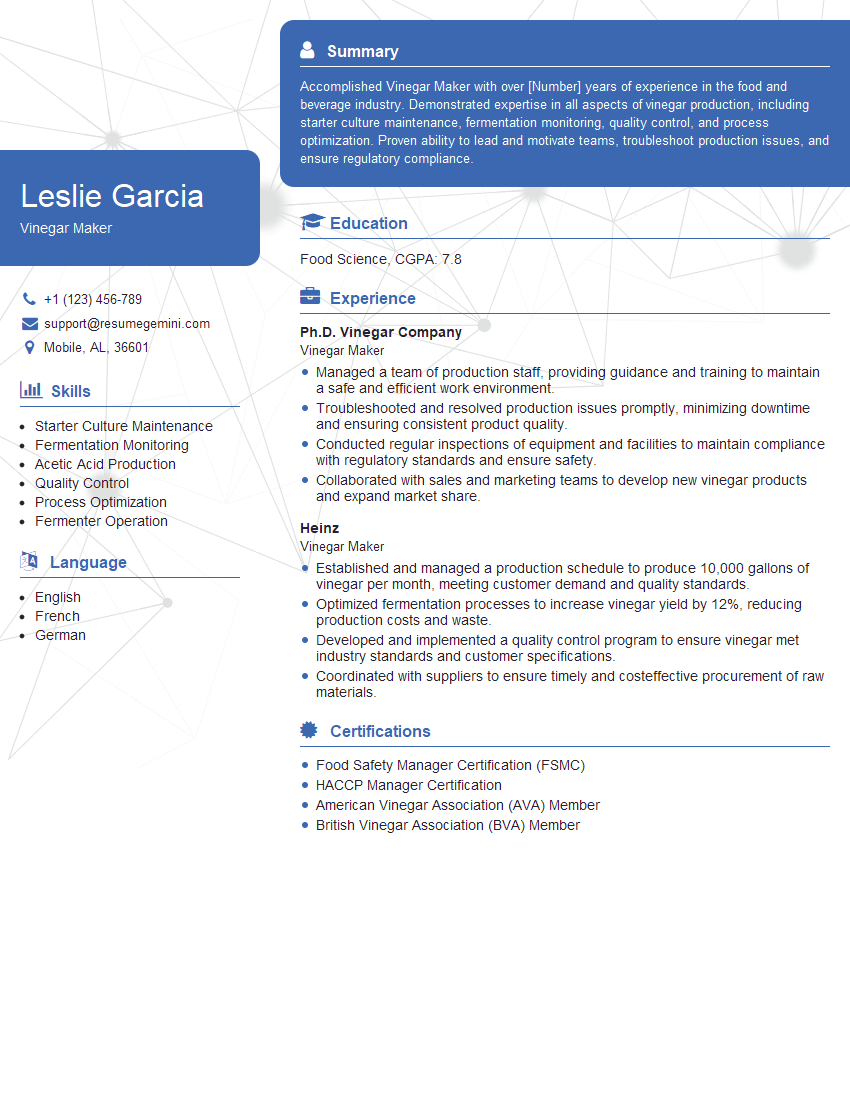

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vinegar Maker

1. Describe the key steps involved in the vinegar production process?

The vinegar production process involves the following key steps:

- Fermentation: The base liquid (usually wine, cider, or fruit juice) is fermented by yeast to produce alcohol.

- Acetic Acid Fermentation: The alcohol is then converted into acetic acid by acetic acid bacteria.

- Aging: The vinegar is aged in barrels or tanks to develop its flavor and aroma.

- Filtration: The vinegar is filtered to remove any impurities.

- Bottling: The vinegar is bottled and labeled.

2. What are the different types of vinegar and how are they produced?

There are many different types of vinegar, each with its own unique flavor and aroma. Some of the most common types of vinegar include:

Apple cider vinegar

- Made from fermented apple cider

- Has a light, fruity flavor

Wine vinegar

- Made from fermented wine

- Has a more complex flavor than apple cider vinegar

Balsamic vinegar

- Made from fermented grape juice

- Has a dark, sweet flavor

Rice vinegar

- Made from fermented rice wine

- Has a light, delicate flavor

Malt vinegar

- Made from fermented barley

- Has a dark, strong flavor

3. What are the quality control measures that are important in vinegar production?

Quality control is essential in vinegar production to ensure that the final product meets the desired standards. Some of the most important quality control measures include:

- Monitoring the fermentation process: The fermentation process must be carefully monitored to ensure that the yeast and bacteria are converting the alcohol into acetic acid at the correct rate.

- Testing the vinegar for acidity: The vinegar must be tested to ensure that it has the correct acidity level.

- Checking the vinegar for clarity: The vinegar must be clear and free of any impurities.

- Tasting the vinegar: The vinegar must be tasted to ensure that it has the desired flavor and aroma.

4. What are the common challenges in vinegar production and how can they be overcome?

There are several common challenges in vinegar production, including:

- Contamination: The vinegar production process can be easily contaminated by bacteria and other microorganisms. This can lead to the production of off-flavors and aromas in the vinegar.

- Oxidation: Vinegar can oxidize when exposed to air, which can cause it to lose its flavor and aroma.

- Temperature control: The fermentation process is sensitive to temperature, and it is important to maintain the correct temperature throughout the process.

These challenges can be overcome by implementing good manufacturing practices, such as:

- Sanitation: The production area and equipment must be kept clean and sanitized to prevent contamination.

- Oxygen control: The vinegar must be stored in airtight containers to prevent oxidation.

- Temperature control: The fermentation process must be carefully monitored and controlled to ensure that the correct temperature is maintained.

5. What are the latest trends in vinegar production?

The latest trends in vinegar production include:

- The use of new technologies: New technologies, such as membrane filtration and reverse osmosis, are being used to improve the efficiency and quality of vinegar production.

- The development of new flavors: New flavors of vinegar, such as fruit-infused vinegars and vinegars made from unique base liquids, are being developed to meet the demands of consumers.

- The growth of the organic vinegar market: The organic vinegar market is growing as consumers become more interested in healthy and sustainable products.

6. What is the role of acetic acid bacteria in vinegar production?

Acetic acid bacteria are responsible for converting alcohol into acetic acid during the vinegar production process. These bacteria are found in the air and on the surface of fruits and vegetables. When they come into contact with an alcoholic liquid, they begin to produce acetic acid. The acetic acid bacteria are also responsible for the development of the vinegar’s flavor and aroma.

7. What factors affect the rate of acetic acid fermentation?

The rate of acetic acid fermentation is affected by several factors, including:

- The concentration of alcohol: The higher the concentration of alcohol, the faster the rate of fermentation.

- The temperature: The optimal temperature for acetic acid fermentation is between 20 and 30 degrees Celsius.

- The presence of oxygen: Oxygen is required for acetic acid fermentation to occur.

- The pH of the solution: The optimal pH for acetic acid fermentation is between 5 and 6.

8. What are the different methods of vinegar production?

There are two main methods of vinegar production:

- The traditional method: This method involves fermenting the base liquid in a barrel or tank. The barrel or tank is left open to the air, allowing the acetic acid bacteria to enter and begin the fermentation process.

- The submerged fermentation method: This method involves fermenting the base liquid in a closed tank. The tank is filled with oxygen to provide the acetic acid bacteria with the oxygen they need to ferment the alcohol.

9. What are the challenges of vinegar production?

There are several challenges associated with vinegar production, including:

- Contamination: The vinegar production process is susceptible to contamination by bacteria and other microorganisms. This can lead to the production of off-flavors and aromas in the vinegar.

- Oxidation: Vinegar can oxidize when exposed to air, which can cause it to lose its flavor and aroma.

- Temperature control: The fermentation process is sensitive to temperature, and it is important to maintain the correct temperature throughout the process.

10. What is the future of vinegar production?

The future of vinegar production is bright. The growing demand for healthy and sustainable products is driving the growth of the vinegar market. New technologies and innovations are also being developed to improve the efficiency and quality of vinegar production. As a result, the vinegar production industry is expected to continue to grow in the years to come.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vinegar Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vinegar Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Vinegar Makers are responsible for producing and maintaining the quality of vinegar, a condiment made from fermented liquids such as wine, cider, or malt. Their key job responsibilities include:

1. Fermentation Management

Supervising and maintaining the fermentation process of vinegar production, ensuring optimal conditions for bacterial growth and conversion of alcohol to acetic acid.

- Monitoring fermentation temperatures and pH levels

- Adjusting sugar and acidity levels as needed

2. Quality Control and Analysis

Performing quality checks throughout the production process to ensure the vinegar meets established standards for flavor, acidity, and appearance.

- Conducting sensory evaluations and chemical analysis

- Identifying and resolving quality issues

3. Equipment Maintenance and Sanitation

Maintaining and cleaning all vinegar production equipment to ensure efficient operation and prevent contamination.

- Cleaning and sterilizing fermentation tanks and pipelines

- Calibrating and maintaining equipment

4. Safety and Regulatory Compliance

Adhering to safety protocols and regulatory requirements related to vinegar production, including handling hazardous chemicals and following food safety regulations.

- Wearing appropriate safety gear

- Maintaining a clean and organized work environment

Interview Tips

To ace an interview for a Vinegar Maker position, candidates should prepare thoroughly and demonstrate their knowledge of the industry, production processes, and quality control.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and production methods. Research the vinegar industry and current trends to demonstrate your understanding of the market.

- Visit the company’s website

- Read industry publications and attend webinars

2. Highlight Relevant Experience and Skills

Emphasize any previous experience in vinegar production or related fields. Describe your role in fermentation management, quality control, and equipment maintenance. Highlight your technical skills and knowledge of food safety regulations.

- Quantify your accomplishments with specific metrics

- Provide examples of your problem-solving abilities

3. Prepare for Technical Questions

Expect questions about fermentation processes, vinegar analysis, and quality control procedures. Be prepared to discuss your understanding of the scientific principles behind vinegar production.

- Review fermentation chemistry and microbiology

- Practice sensory evaluation techniques

4. Show Enthusiasm and Passion

Convey your passion for vinegar making and your desire to contribute to the team. Express your interest in the company’s products and commitment to producing high-quality vinegar.

- Share any personal anecdotes about your love of vinegar

- Ask thoughtful questions about the company’s production process

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Vinegar Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.