Are you gearing up for a career in Viscose Department Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Viscose Department Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

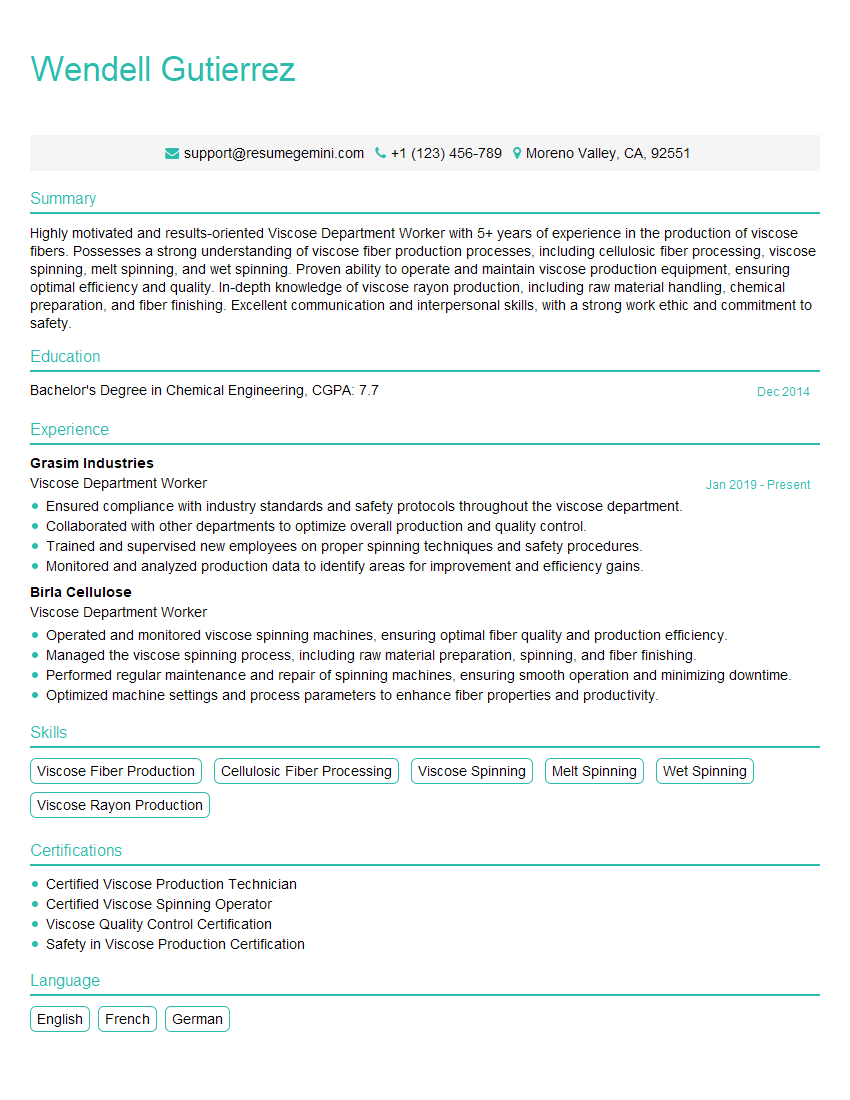

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Viscose Department Worker

1. Explain the process of viscose fiber production?

Viscose fiber production involves the following steps:

- Pulping: Wood pulp is produced by chemically dissolving the lignin, which binds the wood fibers together.

- Steeping: The pulp is treated with sodium hydroxide solution to form cellulose alkali.

- Pressing and Shredding: The cellulose alkali is pressed to remove excess solution, then shredded into crumbs.

- Aging: The crumbs undergo aging under controlled temperature and humidity to mature the cellulose.

- Dissolving: The aged crumbs are dissolved in carbon disulfide to form viscose solution.

- Spinning: The viscose solution is forced through spinnerets into a coagulating bath to form filaments.

- Stretching and Washing: The filaments are stretched to align the cellulose molecules, then washed to remove impurities.

- Drying and Crimping: The fibers are dried and crimped by passing them through hot air and rollers.

2. Describe the different types of viscose fibers and their uses?

There are several types of viscose fibers, each with unique properties and uses:

Regular Viscose

- Strong, absorbent, and drapes well.

- Used in textiles, clothing, household fabrics.

Modal

- Soft, smooth, and has a silky feel.

- Used in bedding, underwear, sportswear.

Tencel

- Biodegradable, environmentally friendly.

- Used in clothing, upholstery, home textiles.

Lyocell

- Strong, wrinkle-resistant, and moisture-wicking.

- Used in clothing, sportswear, medical textiles.

3. What are the key quality parameters for viscose fibers?

The key quality parameters for viscose fibers include:

- Tenacity: Breaking strength of the fiber.

- Elongation: Ability of the fiber to stretch before breaking.

- Modulus: Stiffness of the fiber.

- Absorbency: Ability of the fiber to absorb moisture.

- Opacity: Level of light transmittance through the fiber.

- Whiteness: Brightness and purity of the fiber.

4. How do you control the quality of viscose fibers during production?

Quality control during viscose fiber production involves various measures:

- Raw material inspection: Checking wood pulp for impurities and consistency.

- Process monitoring: Monitoring temperature, pH, and other parameters throughout the production process.

- Fiber testing: Continuously testing fiber samples for tensile strength, elongation, and other quality parameters.

- Statistical process control: Using statistical methods to identify and minimize variations in fiber quality.

- Corrective actions: Implementing corrective actions when quality deviations occur.

5. What are the common defects in viscose fibers and how can they be prevented?

Common defects in viscose fibers include:

- Weak spots: Caused by uneven distribution of cellulose molecules.

- Thick and thin spots: Resulting from variations in nozzle diameter or spinneret temperature.

- Fibrillation: Splitting of the fibers.

- Yellowing: Caused by aging or exposure to sunlight.

- Odor: Unpleasant smell due to residual sulfur compounds.

These defects can be prevented through proper process control, maintenance of equipment, and use of additives.

6. What is the role of a Viscose Department Worker?

The Viscose Department Worker performs various tasks in the production, quality control, and maintenance of viscose fibers.

- Monitoring production processes and ensuring quality standards.

- Conducting fiber testing and recording test results.

- Maintaining equipment, conducting inspections, and making repairs.

- Troubleshooting production issues and implementing corrective actions.

- Following safety protocols and adhering to environmental regulations.

7. How can you troubleshoot a problem with fiber strength?

To troubleshoot fiber strength issues, I would:

- Identify the affected area of the production line: Check raw material, process conditions, and equipment.

- Review process parameters: Ensure that parameters such as temperature, pH, and spinning speed are within specifications.

- Conduct fiber testing: Determine the extent of the strength reduction and identify any specific defects.

- Inspect equipment: Check for worn or damaged components that may affect fiber formation.

- Consult with technical support or engineers: Seek expert advice on potential causes and solutions.

8. How can you improve the productivity of a viscose fiber production line?

To improve productivity, I would focus on:

- Optimizing process parameters: Adjust temperature, pH, and spinning speed to maximize fiber yield and quality.

- Minimizing downtime: Conduct regular maintenance, improve equipment reliability, and train operators on efficient troubleshooting.

- Improving fiber quality: Reduce defects and improve fiber strength, which can increase line efficiency.

- Implementing automation: Use automated systems for process control, monitoring, and data analysis.

- Training and empowering operators: Provide operators with training and resources to optimize their performance and decision-making.

9. What are the safety guidelines for working in a viscose fiber production facility?

Safety guidelines include:

- Personal protective equipment: Wearing appropriate clothing, gloves, respirators, and eye protection.

- Chemical handling: Following protocols for handling corrosive chemicals, such as carbon disulfide.

- Equipment safety: Ensuring that equipment is properly maintained and operated, and avoiding loose clothing or jewelry.

- Fire hazards: Understanding the risks of flammable materials and knowing emergency procedures.

- Emergency response: Being trained on and following emergency response plans for accidents or chemical spills.

10. What are the latest advancements in viscose fiber production technology?

Recent advancements include:

- Novel spinning technologies: Optimizing spinneret design and using new materials for improved fiber properties.

- Sustainable production: Developing processes that minimize environmental impact and use renewable resources.

- Fiber functionalization: Adding specific properties to fibers, such as antibacterial or flame-retardant properties.

- Nanotechnology: Incorporating nanoparticles into fibers for enhanced performance.

- Advanced quality control: Using sensors, data analytics, and automation to improve product consistency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Viscose Department Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Viscose Department Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Viscose Department Workers are responsible for the production of viscose, a type of cellulose fiber used in the manufacture of textiles, paper, and other products. They operate and maintain complex machinery, monitor production processes, and ensure the quality of the finished product.

1. Operate and Maintain Machinery

Viscose Department Workers operate and maintain a variety of machinery, including digesters, spinning machines, and finishing equipment. They are responsible for ensuring that the machinery is running smoothly and efficiently, and for making adjustments as needed.

- Monitor the operation of digesters, spinning machines, and finishing equipment

- Make adjustments to the machinery to ensure that it is running smoothly and efficiently

- Troubleshoot and repair machinery problems

2. Monitor Production Processes

Viscose Department Workers monitor production processes to ensure that they are meeting quality standards. They collect samples of the product at various stages of production and test them for quality.

- Collect samples of the product at various stages of production

- Test the samples for quality

- Make adjustments to the production process as needed to ensure that the product meets quality standards

3. Ensure the Quality of the Finished Product

Viscose Department Workers are responsible for ensuring the quality of the finished product. They inspect the product for defects and make sure that it meets customer specifications.

- Inspect the finished product for defects

- Make sure that the product meets customer specifications

- Reject any product that does not meet quality standards

4. Other Responsibilities

In addition to the above responsibilities, Viscose Department Workers may also be responsible for:

- Cleaning and maintaining the work area

- Loading and unloading raw materials and finished goods

- Assisting other employees in the department

Interview Tips

Preparing for an interview for a Viscose Department Worker position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work in the industry

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, so it is helpful to practice answering them in advance. Some of the most common questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with viscose production?

- How do you handle stress?

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress in business casual attire

- Arrive on time for your interview

- Be polite and respectful to the interviewer

4. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and be enthusiastic about the position. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. And if you’re not excited about the position, it will be hard to convince the interviewer that you’re the right person for the job.

- Be honest and authentic

- Show your enthusiasm for the position

- Be confident in your abilities

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Viscose Department Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!