Are you gearing up for a career in VRT Mechanic (Variable Retention Time Mechanic)? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for VRT Mechanic (Variable Retention Time Mechanic) and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

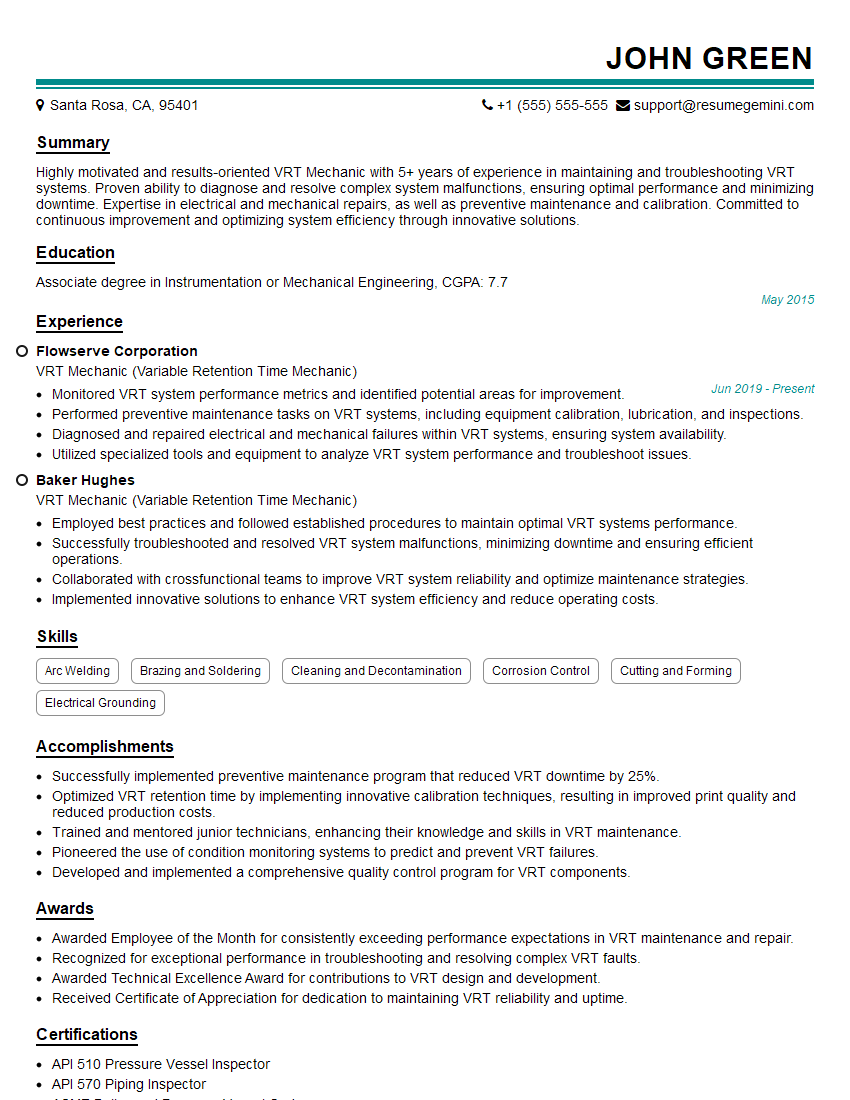

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For VRT Mechanic (Variable Retention Time Mechanic)

1. What is the purpose of using a VRT (Variable Retention Time) machine?

- To separate particles in a fluid sample based on their size and density.

- This allows for the analysis of particle size distribution, concentration, and other physical properties.

2. What are the key components of a VRT machine and how do they work?

Components:

- Sample injection port

- Separation chamber

- Detector

- Data acquisition system

Working:

- Sample is injected into the separation chamber, which contains a carrier fluid.

- Particles in the sample are separated based on their size and density as they flow through the chamber.

- The detector measures the light scattering or other signals generated by the particles.

- The data acquisition system records and analyzes the signals to determine particle size distribution and other properties.

3. How do you calibrate a VRT machine?

- Use standard particles of known size and density.

- Run the particles through the machine and adjust the settings until the measured particle size distribution matches the known values.

- Verify the calibration with additional standard particles.

4. What are the common troubleshooting steps for a VRT machine?

- Check for leaks in the system.

- Verify that the detector is functioning properly.

- Clean the separation chamber and injection port.

- Inspect the carrier fluid for contamination.

5. How do you ensure the accuracy and reliability of VRT measurements?

- Use calibrated standard particles.

- Follow standardized operating procedures.

- Regularly maintain and service the machine.

- Participate in proficiency testing programs.

6. What is the typical workflow for analyzing samples using a VRT machine?

- Prepare the sample by dispersing the particles in a suitable carrier fluid.

- Calibrate the machine using standard particles.

- Inject the sample into the machine.

- Collect and analyze the data.

- Generate a report of the results.

7. How do you interpret the results of a VRT analysis?

- Examine the particle size distribution plot.

- Calculate statistical parameters such as mean particle size, median particle size, and mode particle size.

- Identify any unusual patterns or trends in the data.

- Compare the results to reference data or expected values.

8. What are some of the limitations of VRT analysis?

- Cannot distinguish between particles of different shapes.

- Cannot measure particles smaller than the wavelength of light used in the detector.

- May be affected by particle concentration and carrier fluid viscosity.

9. What are some of the recent advancements in VRT technology?

- Use of advanced detectors, such as laser diffraction and dynamic light scattering.

- Development of new algorithms for data analysis.

- Integration with other analytical techniques, such as microscopy and spectroscopy.

10. How do you stay up-to-date with the latest developments in VRT analysis?

- Attend conferences and workshops.

- Read scientific journals and technical articles.

- Participate in online forums and discussion groups.

- Collaborate with other researchers and practitioners.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for VRT Mechanic (Variable Retention Time Mechanic).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the VRT Mechanic (Variable Retention Time Mechanic)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A VRT Mechanic (Variable Retention Time Mechanic) plays a crucial role in maintaining the efficient operation of a manufacturing or industrial facility. Their primary responsibility is to ensure that all machinery and equipment are running smoothly and within optimal parameters.

1. Equipment Maintenance and Repair

VRT Mechanics perform a wide range of maintenance and repair tasks on various types of equipment, including:

- Conducting regular inspections and preventive maintenance to identify potential issues before they become major problems.

- Troubleshooting and repairing mechanical, electrical, and hydraulic systems

- Replacing worn or damaged components, such as bearings, seals, and gaskets

- Overhauling and rebuilding equipment to extend its lifespan

2. Troubleshooting and Diagnostics

VRT Mechanics are experts in troubleshooting and diagnosing equipment malfunctions. They have a deep understanding of how different systems interact and can quickly identify the root cause of problems. This requires:

- Using diagnostic tools and techniques to identify issues

- Analyzing data and making informed decisions about repairs

- Working closely with other technicians and engineers to resolve complex problems

3. Equipment Optimization

Beyond maintenance and repair, VRT Mechanics also strive to optimize equipment performance and efficiency. They may:

- Fine-tune equipment settings to maximize output and reduce downtime

- Conduct performance evaluations and recommend upgrades or modifications

- Collaborate with design engineers to improve equipment reliability

4. Safety and Compliance

VRT Mechanics are responsible for ensuring that equipment is operated in a safe and compliant manner. They:

- Follow all safety protocols and procedures

- Inspect equipment for potential hazards and make necessary repairs

- Comply with industry regulations and safety standards

Interview Tips

To ace an interview for a VRT Mechanic position, it’s essential to prepare thoroughly and demonstrate your skills and experience effectively.

1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and culture. Understand the specific responsibilities of the VRT Mechanic role and how your skills align with them.

2. Highlight Your Technical Expertise

Provide specific examples of your experience in maintaining and repairing machinery, troubleshooting problems, and optimizing equipment. Use technical terms and jargon to demonstrate your knowledge and proficiency.

3. Showcase Your Problem-Solving Abilities

Describe situations where you successfully diagnosed and resolved complex equipment issues. Emphasize your analytical thinking, attention to detail, and ability to find creative solutions.

4. Emphasize Safety and Compliance

Highlight your commitment to safety and compliance. Discuss your experience in following safety protocols, inspecting equipment for hazards, and adhering to industry regulations.

5. Practice Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about your experience as a VRT Mechanic.

- Describe a challenging project you worked on and how you resolved it.

- What are the most important safety considerations for VRT Mechanics?

- How do you stay updated with the latest industry trends and technologies?

6. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Consider asking about the company’s goals, equipment maintenance practices, or opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the VRT Mechanic (Variable Retention Time Mechanic) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!