Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Vulcanized Fiber Unit Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

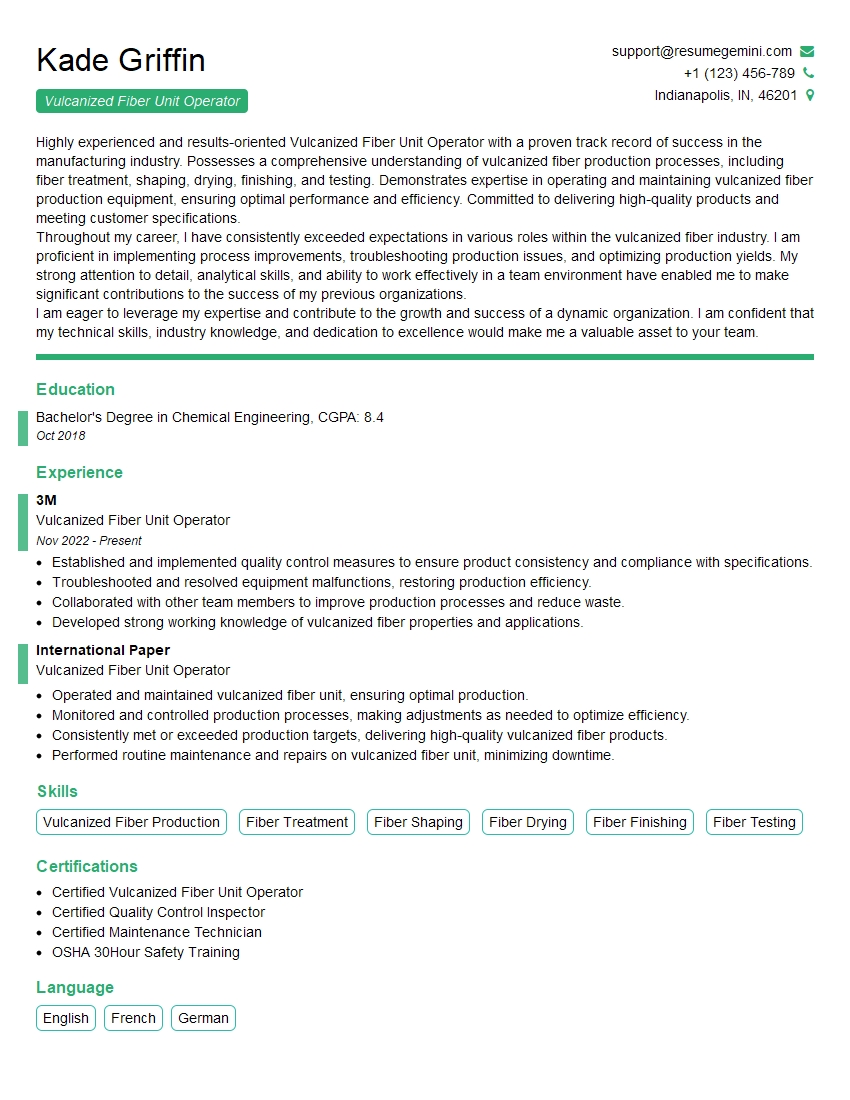

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vulcanized Fiber Unit Operator

1. Describe the process of vulcanizing fiber and the key parameters that need to be controlled during the process?

- Vulcanization is a chemical process that involves treating rubber with sulfur or other curing agents to improve its strength, elasticity, and resistance to heat and wear.

- In vulcanizing fiber, cellulose fibers are treated with sulfur chloride to form a tough, flexible material.

- The key parameters that need to be controlled during the vulcanization process include temperature, pressure, and time.

- If the temperature is too high, the fibers can be damaged.

- If the pressure is too low, the fibers may not be properly vulcanized.

- And if the time is too short, the vulcanization process may not be complete.

2. What are the different types of vulcanized fiber and their applications?

- There are two main types of vulcanized fiber: electrical grade and mechanical grade.

- It is used for electrical insulation in a variety of applications, such as switchboards, circuit breakers, and transformers.

- It has high dielectric strength, arc resistance, and flame resistance.

- It is used for a variety of mechanical applications, such as gears, bearings, and washers.

- It has high strength, stiffness, and wear resistance.

Electrical grade vulcanized fiber

Mechanical grade vulcanized fiber

3. How do you ensure the quality of vulcanized fiber products?

- I ensure the quality of vulcanized fiber products by following strict quality control procedures.

- These procedures include:

- Inspecting raw materials

- Monitoring the vulcanization process

- Testing finished products

- I also work closely with our customers to ensure that our products meet their specific requirements.

4. What are the safety precautions that need to be taken when working with vulcanized fiber?

- The following safety precautions should be taken when working with vulcanized fiber:

- Wear gloves and eye protection.

- Avoid contact with skin and eyes.

- Do not breathe in dust or fumes.

- Use proper ventilation.

- Store vulcanized fiber in a cool, dry place.

5. What are the challenges you have faced in your previous role as a Vulcanized Fiber Unit Operator?

- One of the challenges I faced in my previous role was ensuring the consistent quality of vulcanized fiber products.

- This required me to carefully monitor the vulcanization process and make adjustments as needed.

- Another challenge was meeting the increasing demand for our products while maintaining high quality standards.

- I was able to overcome these challenges by working closely with my team and implementing new quality control measures.

6. What are your strengths and weaknesses as a Vulcanized Fiber Unit Operator?

Strengths

- Strong understanding of the vulcanization process

- Proven ability to produce high-quality vulcanized fiber products

- Excellent problem-solving skills

- Strong work ethic

- Team player

Weaknesses

- Can be impatient at times

- Not always the best at delegating tasks

7. Why are you interested in working as a Vulcanized Fiber Unit Operator for our company?

- I am interested in working as a Vulcanized Fiber Unit Operator for your company because I am impressed with your commitment to quality and innovation.

- I believe that my skills and experience would be a valuable asset to your team.

- I am eager to learn more about the vulcanization process and to contribute to the success of your company.

8. What are your salary expectations for this role?

- My salary expectations for this role are in line with the industry average for Vulcanized Fiber Unit Operators with my experience and qualifications.

- I am also open to discussing a salary range that is competitive and commensurate with my value to your company.

9. What is your availability to start work?

- I am available to start work immediately.

- I am flexible with my start date and can accommodate your company’s needs.

10. Do you have any questions for me?

- I am interested in learning more about the company’s quality control procedures for vulcanized fiber products.

- I would also like to know more about the company’s plans for future growth.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vulcanized Fiber Unit Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vulcanized Fiber Unit Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Vulcanized Fiber Unit Operator is responsible for operating and maintaining vulcanizing machinery to produce fiber products. Key job responsibilities include:

1. Operating Vulcanizing Equipment

Operating vulcanizing equipment, including presses, molds, and ovens.

- Monitoring equipment conditions and making necessary adjustments.

- Loading and unloading materials from equipment

2. Maintaining Vulcanizing Equipment

Performing preventive maintenance on vulcanizing equipment, including cleaning, lubrication, and repairs.

- Troubleshooting and resolving equipment problems

- Ordering and maintaining spare parts

3. Quality Control

Inspecting vulcanized products for quality and conformance to specifications.

- Identifying and correcting defects

- Maintaining quality control records

4. Production Monitoring

Monitoring production levels and ensuring that targets are met.

- Adjusting production schedules as needed

- Reporting production data to supervisors

Interview Tips

To ace the interview for a Vulcanized Fiber Unit Operator position, it is crucial to prepare thoroughly and showcase your skills and knowledge. Here are some interview tips and hacks:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific role. This will demonstrate your interest in the position and help you tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their products, services, and culture.

- Read industry publications and news articles to stay up-to-date on the latest trends and advancements in vulcanized fiber production.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the job responsibilities. Quantify your accomplishments whenever possible to showcase your impact.

- Discuss your experience operating and maintaining vulcanizing equipment.

- Provide examples of how you have identified and resolved equipment problems.

- Highlight your quality control experience and your ability to meet production targets.

3. Prepare for Technical Questions

Expect to be asked technical questions about vulcanizing processes and equipment. Review the basics of vulcanization, including the different types of materials used and the process parameters involved.

- Be prepared to discuss the different types of vulcanizing presses and their applications.

- Explain the importance of temperature, pressure, and time in the vulcanization process.

- Describe the different methods used for testing vulcanized products.

4. Practice Your Answers

Practice answering common interview questions out loud. This will help you become more comfortable and confident during the actual interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result).

- Ask a friend or family member to conduct mock interviews with you.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Vulcanized Fiber Unit Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.