Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Vulcanizer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

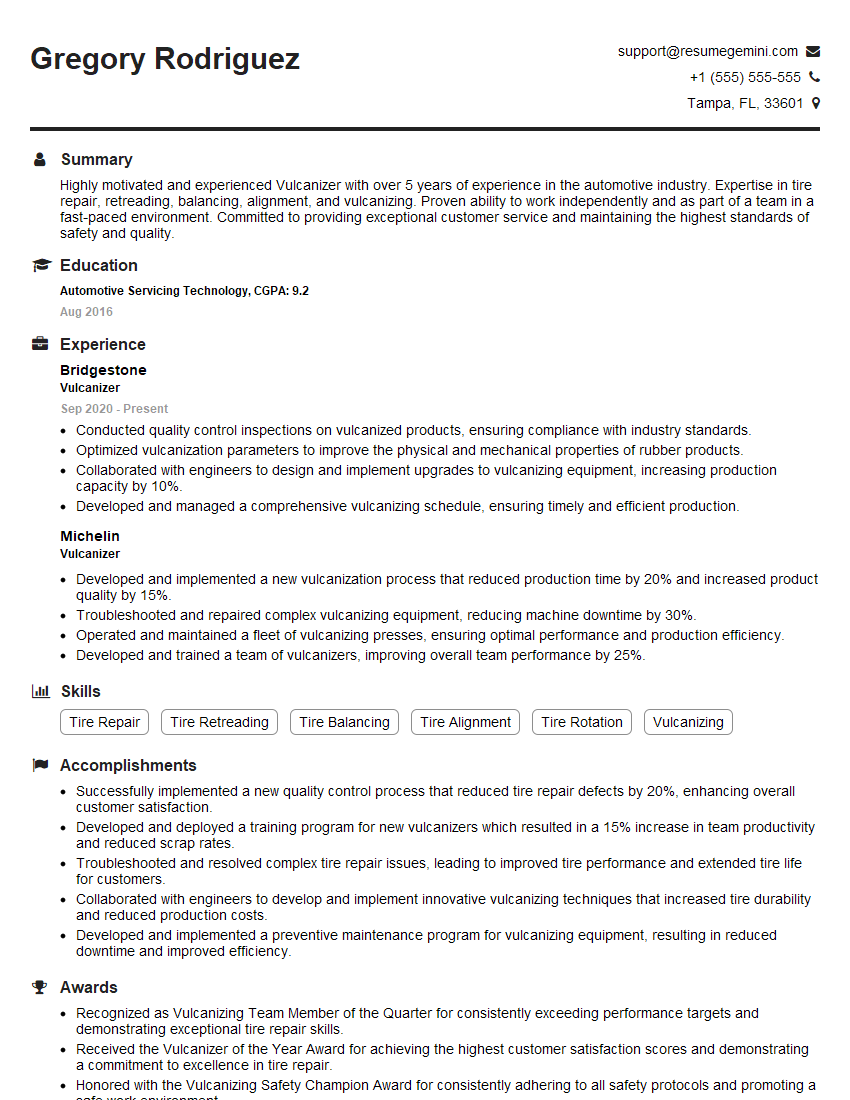

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vulcanizer

1. Describe the process of vulcanizing rubber.

Vulcanizing rubber is a chemical process that converts natural or synthetic rubber into a more durable and elastic material. The process involves heating the rubber in the presence of sulfur or other cross-linking agents, which form chemical bonds between the rubber molecules.

- The rubber is first mixed with sulfur and other ingredients in a rubber mill.

- The mixture is then heated in a mold or press under high pressure and temperature.

- The heat and pressure cause the sulfur to react with the rubber molecules, forming cross-links between them.

- The resulting vulcanized rubber is stronger, more elastic, and more resistant to heat and chemicals than unvulcanized rubber.

2. What are the different types of vulcanizing processes?

There are two main types of vulcanizing processes: hot vulcanization and cold vulcanization.

Hot vulcanization

- Hot vulcanization is the most common type of vulcanizing process. It involves heating the rubber in a mold or press under high pressure and temperature.

- Hot vulcanization produces a stronger and more durable product than cold vulcanization.

Cold vulcanization

- Cold vulcanization is a process that does not require heat. Instead, the rubber is mixed with a chemical curing agent and allowed to cure at room temperature.

- Cold vulcanization produces a more flexible product than hot vulcanization.

3. What are the factors that affect the vulcanization process?

The vulcanization process is affected by a number of factors, including:

- The type of rubber being used

- The amount of sulfur or other cross-linking agents being used

- The temperature and pressure of the vulcanization process

- The duration of the vulcanization process

4. What are the properties of vulcanized rubber?

Vulcanized rubber has a number of properties that make it a valuable material for a wide range of applications, including:

- Strength and durability

- Elasticity and flexibility

- Resistance to heat and chemicals

- Electrical insulation

5. What are the applications of vulcanized rubber?

Vulcanized rubber is used in a wide range of applications, including:

- Tires

- Belts and hoses

- Gaskets and seals

- Electrical insulation

- Medical devices

6. What are the safety precautions that should be taken when working with vulcanized rubber?

Vulcanized rubber is a safe material to work with, but there are a few safety precautions that should be taken, including:

- Wearing gloves and a mask when handling vulcanized rubber

- Working in a well-ventilated area

- Avoiding contact with the eyes and skin

7. What are the troubleshooting tips for vulcanized rubber?

If you are having trouble with vulcanized rubber, there are a few troubleshooting tips that you can try, including:

- Checking the temperature and pressure of the vulcanization process

- Checking the duration of the vulcanization process

- Checking the type of rubber being used

- Checking the amount of sulfur or other cross-linking agents being used

8. What are the future trends in vulcanized rubber?

The future of vulcanized rubber looks bright. There are a number of new developments in the field of vulcanization, including:

- The development of new types of vulcanized rubber with improved properties

- The development of new vulcanization processes that are more efficient and environmentally friendly

- The development of new applications for vulcanized rubber

9. What are the challenges facing the vulcanized rubber industry?

The vulcanized rubber industry faces a number of challenges, including:

- The rising cost of raw materials

- The increasing demand for vulcanized rubber

- The development of new materials that are competing with vulcanized rubber

10. What are the opportunities for the vulcanized rubber industry?

The vulcanized rubber industry has a number of opportunities for growth, including:

- The development of new types of vulcanized rubber with improved properties

- The development of new vulcanization processes that are more efficient and environmentally friendly

- The development of new applications for vulcanized rubber

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vulcanizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vulcanizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Vulcanizers are responsible for repairing and maintaining rubber products, such as tires, tubes, and hoses. They use specialized equipment and techniques to vulcanize rubber, which is a process that bonds rubber molecules together. Key job responsibilities include:

1. Inspecting and assessing rubber products

Vulcanizers inspect and assess rubber products to identify any damage or wear. They use visual inspection, as well as specialized tools and equipment, to determine the extent of the damage and the best course of action for repair.

- Inspecting rubber products for damage, wear, and leaks

- Assessing the extent of the damage and determining the best course of action for repair

2. Preparing rubber products for repair

Vulcanizers prepare rubber products for repair by cleaning and preparing the surface of the rubber. They may also apply a sealant or adhesive to the surface of the rubber to help the repair adhere.

- Cleaning and preparing the surface of the rubber

- Applying a sealant or adhesive to the surface of the rubber

3. Vulcanizing rubber products

Vulcanizers vulcanize rubber products by exposing them to heat and pressure. This process bonds the rubber molecules together and creates a strong, durable repair.

- Exposing rubber products to heat and pressure

- Monitoring the vulcanization process to ensure that the rubber is properly cured

4. Testing and inspecting repaired rubber products

Vulcanizers test and inspect repaired rubber products to ensure that they are safe and meet quality standards. They may use a variety of tests, including visual inspection, pressure testing, and leak testing.

- Testing repaired rubber products to ensure that they are safe and meet quality standards

- Documenting the results of the tests and inspections

Interview Tips

Preparing for an interview for a Vulcanizer position can be a daunting task, but by following these tips, you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position. You can find this information on the company’s website, in industry publications, or by talking to people who work for the company.

- Visit the company’s website to learn about their history, mission, and values

- Read industry publications to learn about the latest trends and technologies in the vulcanizing industry

- Talk to people who work for the company to get their insights on the company culture and the position you are applying for

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Prepare examples of your work experience that demonstrate your skills and abilities

- Practice your answers with a friend or family member

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire

- Be on time for your interview

- Make eye contact and shake the interviewer’s hand firmly

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the position and the company. Show the interviewer that you are excited about the opportunity to work for the company and that you are confident in your abilities.

- Be yourself and let your personality shine through

- Smile and make eye contact with the interviewer

- Be positive and enthusiastic about the position and the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Vulcanizer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.