Are you gearing up for an interview for a Vulcanizing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Vulcanizing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

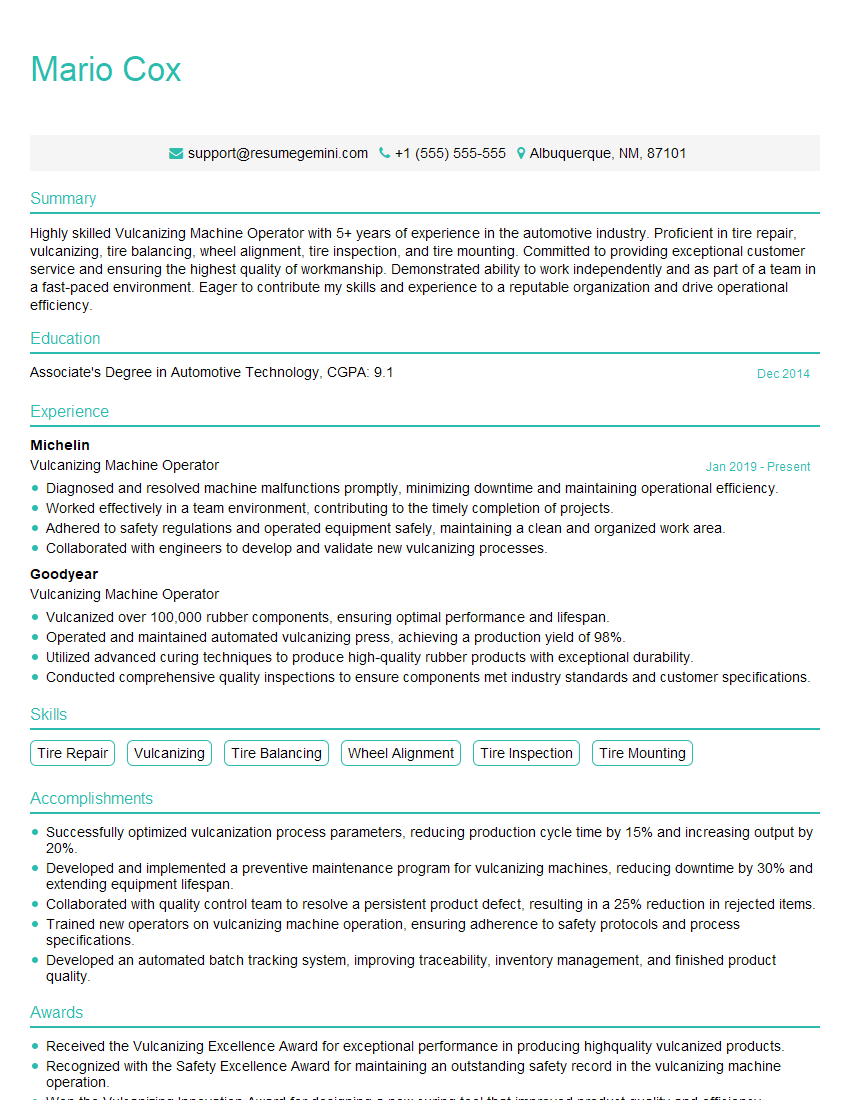

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vulcanizing Machine Operator

1. Explain the role of a Vulcanizing Machine Operator in the tire manufacturing process?

The Vulcanizing Machine Operator is responsible for operating and maintaining the vulcanizing machine, which is used to vulcanize or cure rubber tires. The vulcanizing process involves heating the tire under pressure to activate the sulfur and promote cross-linking, resulting in the formation of strong and durable rubber.

2. Describe the different types of vulcanizing machines and their specific functions?

- Horizontal Vulcanizing Machine: Used for curing small to medium-sized tires, typically for passenger cars and light trucks. It has a horizontal mold cavity where the uncured tire is placed inside and heated from the sides.

- Vertical Vulcanizing Machine: Designed for curing large and heavy tires, such as those used in trucks, buses, and earth-moving equipment. It has a vertical mold cavity where the tire is suspended from above and heated from all sides.

- Bladder Vulcanizing Machine: Employs a flexible rubber bladder that conforms to the shape of the uncured tire. Hot water or steam is circulated inside the bladder to heat the tire evenly.

3. How do you ensure the quality of the vulcanized tires?

- Visual Inspection: Examining the tires for any visible defects, such as cracks, blisters, or uneven surfaces.

- Dimensional Measurement: Using calipers or gauges to verify that the tires meet the specified dimensions, such as diameter, width, and tread depth.

- Hardness Testing: Measuring the hardness of the rubber using a durometer to ensure it meets the desired specifications.

- Performance Testing: Conducting tests on the vulcanized tires, such as inflation pressure resistance, load-bearing capacity, and tread wear to assess their performance.

4. Describe the safety precautions that must be taken when operating a vulcanizing machine?

- Wear appropriate protective gear: Including safety glasses, gloves, earplugs, and a face mask to protect from fumes and particles.

- Follow proper handling procedures: Use lifting equipment to move heavy tires and ensure they are properly secured before vulcanization.

- Maintain the machine regularly: Regularly inspect and maintain the machine to prevent malfunctions or accidents.

- Be aware of the potential hazards: Such as high temperatures, pressure, and rotating parts.

5. How do you troubleshoot common problems that may occur during the vulcanization process?

- Undercure: Caused by insufficient temperature or pressure during vulcanization, resulting in weak or brittle tires.

- Overcure: Caused by excessive temperature or pressure, leading to stiff and non-resilient tires.

- Blisters: Formation of air pockets within the tire due to trapped air or moisture.

- Cracks: Caused by exposure to extreme temperatures or mechanical stress.

6. Explain the importance of proper mold design and maintenance for effective vulcanization?

- Mold Design: The mold cavity must be designed to ensure proper tire shape, tread pattern, and dimensional accuracy.

- Mold Maintenance: Regular cleaning and inspection of the mold is crucial to prevent contamination or damage that could affect the quality of the vulcanized tires.

- Cooling Channels: Molds must have cooling channels to dissipate heat and ensure uniform vulcanization.

7. What is the role of temperature and pressure in the vulcanization process?

Temperature and pressure play crucial roles in the vulcanization process:

- Temperature: The optimum temperature range for vulcanization varies depending on the type of rubber compound used. Adequate heat activates the sulfur and promotes cross-linking.

- Pressure: Pressure is applied to the tire during vulcanization to ensure proper contact between the uncured rubber and the mold cavity, resulting in a compact and uniform tire.

8. Describe the different methods used to heat the vulcanizing mold?

- Steam Heating: Hot steam is circulated through channels in the mold to provide heat.

- Electrical Heating: Electrical resistance elements are embedded in the mold to generate heat.

- Hot Water Heating: Hot water is circulated through channels in the mold.

9. Explain the purpose of a curing bag and how it affects the vulcanization process?

A curing bag is a flexible container placed inside the vulcanizing mold. It:

- Conforms to the shape of the tire: Ensuring proper contact between the tire and the mold.

- Provides pressure: When inflated with air or steam, it applies pressure to the tire during vulcanization.

- Protects the tire: From direct exposure to the heat and pressure of the vulcanizing machine.

10. Describe the different types of defects that can occur during vulcanization and their potential causes?

- Porosity: Air bubbles trapped within the tire due to insufficient pressure or air entrapment.

- Cracking: Caused by excessive heat, pressure, or mechanical stress.

- Scorching: Overheating of the rubber compound, resulting in a burnt and brittle appearance.

- Blisters: Formation of air pockets due to moisture or trapped air.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vulcanizing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vulcanizing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Vulcanizing Machine Operator, you’ll play a crucial role in the manufacturing process, ensuring the production of high-quality rubber products.

1. Operate Vulcanizing Machines

Your primary responsibility will be operating vulcanizing machines, which apply heat and pressure to rubber to transform it into a more durable and resilient material.

- Monitor and adjust machine settings, including temperature, pressure, and curing time, to achieve optimal vulcanization.

- Load and unload rubber molds and ensure proper positioning and alignment.

2. Inspect and Maintain Vulcanized Products

Once the vulcanization process is complete, you’ll inspect the finished products for any defects or nonconformities.

- Visually examine products for imperfections, such as surface irregularities, bubbles, or cracks.

- Conduct physical tests to assess the product’s strength, elasticity, and resistance to wear and tear.

3. Calibrate and Maintain Equipment

To ensure accurate and efficient vulcanization, you’ll regularly calibrate and maintain vulcanizing machines and related equipment.

- Follow recommended maintenance schedules for inspecting, cleaning, and lubricating machines.

- Troubleshoot and resolve any technical issues that arise during operation.

4. Follow Safety Protocols

Working with vulcanizing machines requires strict adherence to safety protocols.

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

- Operate machines in a safe and responsible manner to prevent accidents.

Interview Tips

Preparing for a Vulcanizing Machine Operator interview requires a combination of technical knowledge and a strong emphasis on safety.

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and values. Research the specific responsibilities and requirements of the Vulcanizing Machine Operator position.

- Visit the company website and LinkedIn profile to gather information.

- Read industry-related news and articles to stay informed about current practices.

2. Highlight Your Technical Skills

Emphasize your experience in operating vulcanizing machines and related equipment. Quantify your accomplishments whenever possible.

- Provide specific examples of how you maintained and calibrated machines to ensure optimal performance.

- Describe your troubleshooting skills and how you resolved technical issues.

3. Demonstrate Your Safety Awareness

Safety is paramount in this role. Showcase your understanding of safety protocols and your commitment to following them.

- Highlight your experience in wearing and maintaining PPE.

- Explain your knowledge of safe machine operation and emergency procedures.

4. Prepare to Discuss Your Motivation

Explain why you’re interested in the Vulcanizing Machine Operator position and how it aligns with your career goals.

- Share your passion for manufacturing and your desire to contribute to the production of high-quality products.

- Emphasize your willingness to work in a hands-on environment and your attention to detail.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Vulcanizing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!