Are you gearing up for an interview for a Wad Lubricator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wad Lubricator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

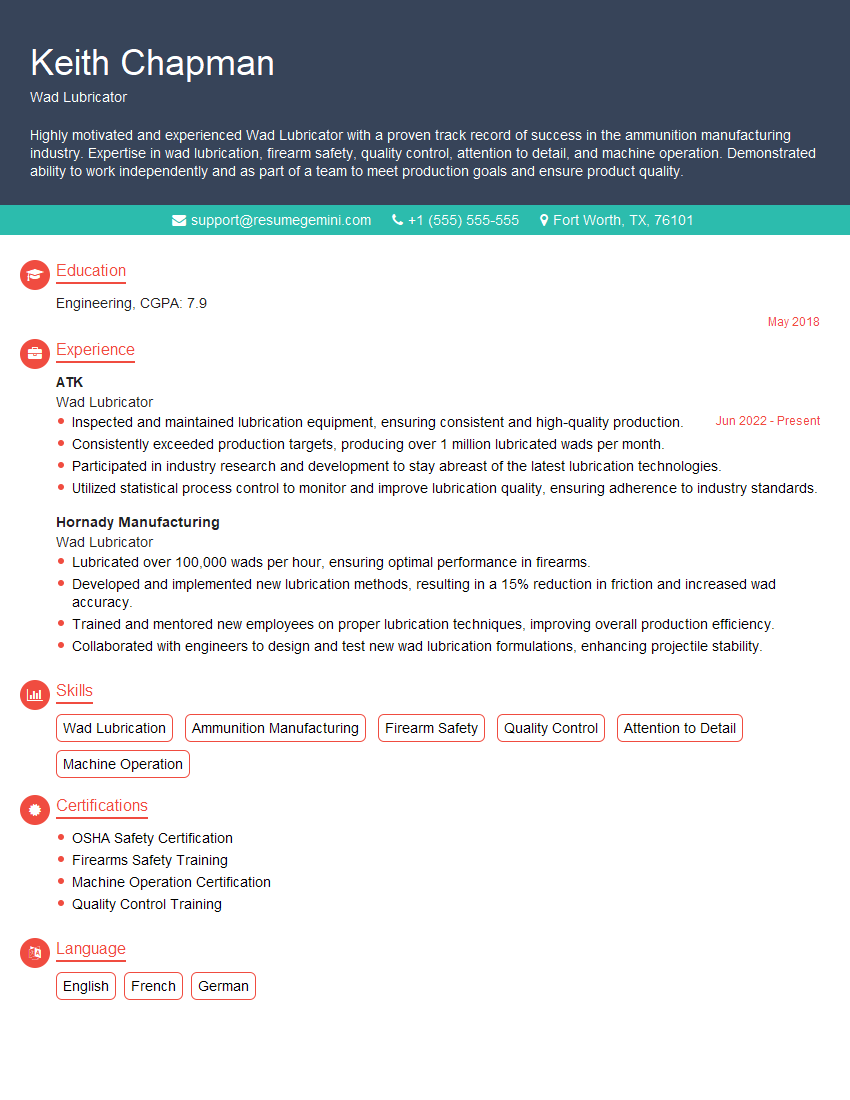

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wad Lubricator

1. What are your responsibilities as a Wad Lubricator?

- Maintain and clean wad lubricating and cut-off machines.

- Ensure correct lubrication and alignment of wads.

- Inspect and test wads for quality and conformance to specifications.

- Monitor and adjust machine settings to optimize production efficiency.

- Troubleshoot and repair machine malfunctions.

2. Explain the different types of wads and their functions.

Types of wads

- Fiber wads: Absorb recoil and protect the shot.

- Plastic wads: Provide buffering between the shot and powder, and improve shot patterns.

- Cork wads: Used in muzzleloading firearms to seal the bore and prevent gas leakage.

Their functions

- Reduce friction and wear on the barrel.

- Protect the shot from damage.

- Improve shot patterns and accuracy.

- Seal the bore and prevent gas leakage.

3. Describe the process of lubricating and cutting wads.

- Wads are fed into the lubricating machine, which applies a thin layer of lubricant to the wad’s surface.

- Lubricated wads are then fed into the cut-off machine, which cuts them to the desired length and shape.

- Cut wads are inspected for quality and conformance to specifications.

4. How do you ensure the quality of lubricated wads?

- Inspect wads for proper lubrication and cut.

- Test wads for consistency in weight and dimensions.

- Monitor machine settings to ensure optimal lubrication and cutting.

- Document all quality control checks and results.

5. What are some common problems that occur during wad lubrication and how do you troubleshoot them?

- Insufficient lubrication: Check lubricant supply and adjust machine settings.

- Uneven lubrication: Clean and inspect lubricant applicator.

- Wads not cutting cleanly: Check blade sharpness and adjust cutting machine settings.

- Wads not meeting specifications: Inspect machine settings and recalibrate as necessary.

6. Describe your experience in working with different types of lubrication equipment.

- Worked with manual and automatic wad lubricating machines.

- Experience in setting up, operating, and maintaining lubrication equipment.

- Familiar with different types of lubricants and their application techniques.

7. How do you maintain and calibrate wad lubricating equipment?

- Regularly clean and inspect equipment for wear and tear.

- Lubricate moving parts as per manufacturer’s recommendations.

- Calibrate equipment using standard wads and reference measurements.

- Document all maintenance and calibration activities.

8. What safety precautions do you take when working with wad lubricating equipment?

- Wear appropriate safety gear, including gloves and eye protection.

- Ensure equipment is properly grounded to prevent electrical hazards.

- Follow lockout/tagout procedures when performing maintenance or repairs.

- Report any safety concerns or incidents promptly.

9. What are your goals for this role and how do you plan to contribute to our team?

- Goals: Improve production efficiency, maintain quality standards, and support the team in achieving its objectives.

- Contribution: Utilize my experience in wad lubrication to optimize machine performance, ensure product quality, and contribute to the team’s success.

10. Do you have any questions for us about the role or the company?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wad Lubricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wad Lubricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Wad Lubricator is a skilled professional responsible for ensuring the smooth and efficient operation of machinery by lubricating wads or other components of weapons systems. They play a crucial role in maintaining the functionality and performance of various types of weapons, contributing to their reliability and accuracy.

1. Inspect and Lubricate Wads

Inspect wads to ensure they meet specified quality standards and are free from defects.

- Meticulously apply lubricants to wads using specialized equipment.

- Monitor and maintain optimum lubrication levels to enhance weapon performance.

2. Maintain Lubrication Equipment

Regularly inspect and maintain lubrication equipment, including dispensers and applicators.

- Calibrate and adjust equipment to ensure accurate lubrication.

- Perform routine maintenance tasks to prevent equipment malfunctions and ensure reliability.

3. Maintain Inventory and Records

Maintain inventory of lubricants, wads, and associated materials.

- Keep accurate records of lubrication activities, including dates, quantities, and specifications.

- Monitor stock levels and initiate procurement procedures to avoid shortages.

4. Adhere to Safety Regulations

Strictly adhere to safety protocols and guidelines related to handling lubricants and operating equipment.

- Wear appropriate personal protective equipment (PPE) to minimize exposure to hazardous substances.

- Follow established procedures for safe disposal of used lubricants and materials.

Interview Tips

Preparing for an interview for a Wad Lubricator position requires a combination of technical knowledge and interpersonal skills. Here are some tips and hacks to help you ace the interview and leave a lasting impression on potential employers:

1. Research the Company and Position

Thoroughly research the company, its industry, and the specific responsibilities of the Wad Lubricator role. This knowledge will demonstrate your interest and understanding of the position.

- Visit the company’s website to gather information about their products, services, and mission.

- Read industry publications and articles to stay up-to-date with the latest trends and best practices in lubrication.

2. Highlight Your Technical Expertise

Emphasize your technical skills and experience in lubrication, especially in relation to weapons systems. Provide specific examples of how you have successfully lubricated wads and maintained lubrication equipment.

- Discuss your knowledge of different types of lubricants and their applications.

- Explain your understanding of the principles of lubrication and how they impact weapon performance.

3. Showcase Your Attention to Detail

Wad Lubricators must be highly detail-oriented to ensure precise lubrication and maintain accurate records. Highlight your ability to follow instructions carefully and perform tasks with meticulous precision.

- Describe a situation where you successfully followed complex lubrication procedures.

- Provide examples of how you maintain organized records and track inventory effectively.

4. Practice Your Communication Skills

Wad Lubricators often interact with colleagues, supervisors, and clients. Demonstrate your ability to communicate clearly, both verbally and in writing. Be prepared to answer questions and articulate your thoughts concisely.

- Prepare for common interview questions such as “Tell me about yourself” and “Why are you interested in this position?”

- Practice delivering clear and informative answers that highlight your relevant skills and experience.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare a list of questions that demonstrate your understanding of the role and the company.

- Inquire about the specific challenges and opportunities associated with the position.

- Ask about the company’s plans for growth and innovation in the lubrication field.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wad Lubricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!