Feeling lost in a sea of interview questions? Landed that dream interview for Wad Printing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wad Printing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

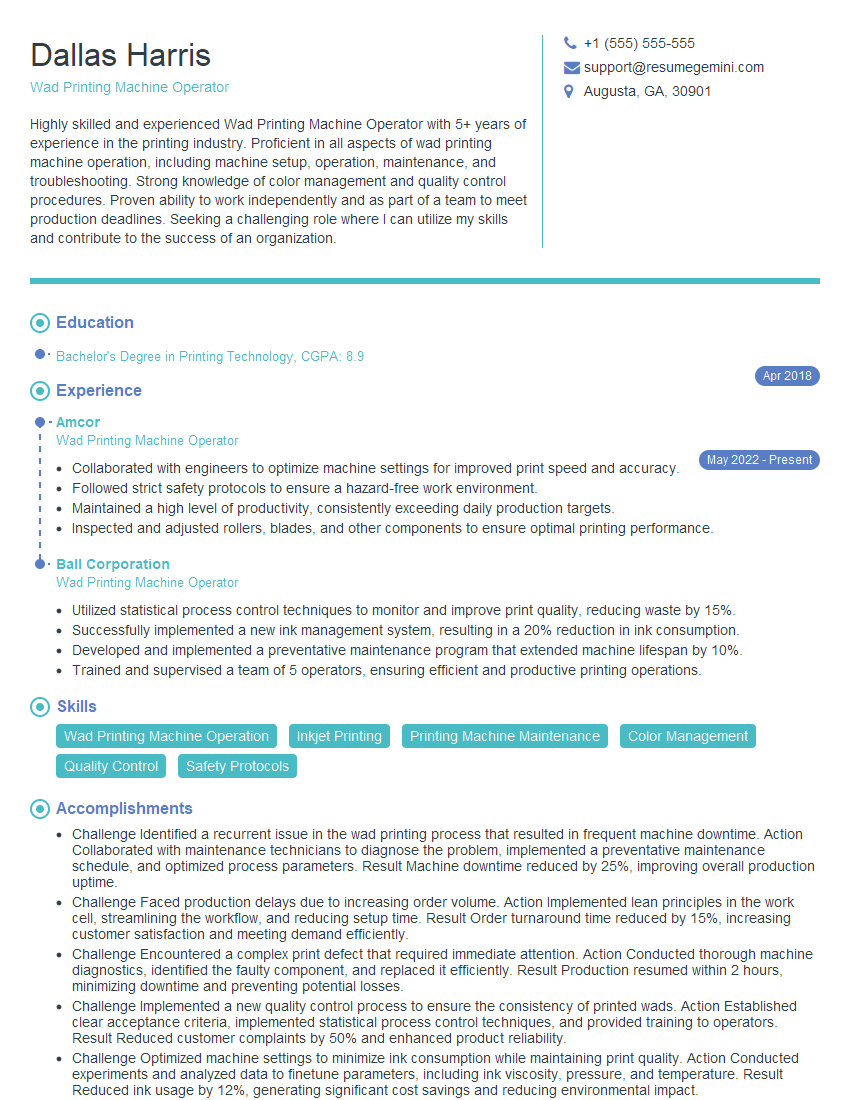

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wad Printing Machine Operator

1. How do you ensure that the ink viscosity is maintained within the specified range?

To maintain the ink viscosity within the specified range, I follow these steps:

- Regularly monitor the ink viscosity using a viscometer.

- Adjust the ink temperature and/or add appropriate solvents or reducers as needed.

- Ensure that the ink is thoroughly mixed before printing to avoid viscosity variations.

- Calibrate the viscometer regularly to ensure accurate readings.

2. Describe the process of registering the print image on the wad.

Pre-Registration

- Check the die alignment and adjust as necessary.

- Mark registration targets on the wad.

Registration

- Load the wad into the registration station.

- Align the wad using the registration targets.

- Print a small test pattern to verify registration.

- Make fine adjustments to the registration if needed.

Post-Registration

- Inspect the wad to ensure proper registration.

- Print the full image on the wad.

3. How do you troubleshoot print defects such as smudging or ink streaking?

To troubleshoot print defects like smudging or ink streaking, I follow these steps:

- Identify the source of the problem (e.g., ink viscosity, plate wear, machine settings).

- Check the ink viscosity and adjust if necessary.

- Inspect the printing plates for damage or wear and replace if needed.

- Verify the machine settings (e.g., impression pressure, printing speed) and make adjustments.

- Clean the ink rollers and other components thoroughly.

4. What is the purpose of the nip rollers in a wad printing machine?

The nip rollers in a wad printing machine serve several important purposes:

- Maintain the proper tension of the wad material during printing.

- Provide pressure to transfer the ink from the printing plate to the wad.

- Control the thickness of the printed layer by adjusting the gap between the rollers.

- Prevent the wad from slipping or wrinkling during the printing process.

5. How do you maintain the cleanliness of the printing machine and its components?

To maintain the cleanliness of the printing machine and its components, I follow these practices:

- Regularly clean the printing plates, rollers, and other components with appropriate solvents.

- Inspect the machine regularly for any signs of wear or damage and address them promptly.

- Use a vacuum cleaner to remove dust and debris from the machine.

- Keep the work area clean and organized to prevent contamination.

6. What is the importance of using the correct ink for wad printing?

Using the correct ink for wad printing is essential for several reasons:

- Ensuring print quality: Appropriate inks provide optimal adhesion, color reproduction, and durability.

- Preventing machine damage: Using incompatible inks can damage the printing machine’s components.

- Meeting safety requirements: Inks must comply with industry standards and regulations for health and safety.

- Achieving specific effects: Different inks offer varying properties, such as gloss, opacity, and special effects.

7. How do you identify and resolve mechanical issues with the wad printing machine?

To identify and resolve mechanical issues with the wad printing machine, I follow these steps:

- Observe the machine’s operation: Listen for unusual noises, vibrations, or other anomalies.

- Check for loose or damaged components: Inspect belts, gears, and other parts for wear or breakage.

- Review error messages: The machine’s display may provide error codes or messages that indicate the issue.

- Use diagnostic tools: Utilize multimeters, gauges, or other tools to test electrical components or measure parameters.

- Refer to maintenance manuals: Consult technical documentation to troubleshoot specific issues.

8. What is the role of the drying oven in the wad printing process?

The drying oven in the wad printing process plays a crucial role in:

- Drying the printed ink: The oven’s heat accelerates the evaporation of solvents, ensuring proper ink adhesion and curing.

- Preventing smudging: Drying the ink quickly prevents it from smearing or smudging during handling.

- Enhancing print quality: Proper drying improves the color vibrancy, sharpness, and durability of the printed image.

9. How do you optimize the printing speed for maximum efficiency without compromising quality?

To optimize printing speed for maximum efficiency without compromising quality, I consider the following factors:

- Ink viscosity: Higher viscosity inks require slower speeds to ensure proper transfer and drying.

- Wad material: Thicker or more absorbent wads may require slower speeds to allow for sufficient ink penetration.

- Printing resolution: Higher resolutions require slower speeds to achieve accurate and detailed images.

- Drying time: Ensure that the printing speed allows adequate drying time before the wads are handled or stacked.

10. What are the key maintenance tasks you perform to ensure the smooth operation of the wad printing machine?

To ensure the smooth operation of the wad printing machine, I perform these key maintenance tasks:

- Regular cleaning: Clean the printing plates, rollers, and other components to remove ink residue and prevent buildup.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations to minimize friction and wear.

- Inspections: Conduct regular inspections to identify and address any loose or damaged components.

- Adjustments: Make necessary adjustments to printing pressure, ink flow, and other settings to optimize performance.

- Calibration: Calibrate the machine periodically to ensure accurate registration and print quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wad Printing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wad Printing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wad Printing Machine Operators are responsible for operating and maintaining wad printing machines, which are used to print designs and patterns onto wads, which are thin layers of material used in various industries such as packaging and construction.

1. Operating the Printing Machine

Wad Printing Machine Operators are responsible for setting up and operating the printing machine, ensuring that it is running smoothly and efficiently.

- Loading and unloading wads from the machine

- Monitoring the printing process and making adjustments as needed

2. Maintaining the Printing Machine

Wad Printing Machine Operators are responsible for maintaining the printing machine, ensuring that it is in good working order and that any necessary repairs are made promptly.

- Performing routine maintenance and cleaning

- Inspecting the machine regularly for any signs of wear or damage

3. Quality Control

Wad Printing Machine Operators are responsible for ensuring that the printed wads meet the required quality standards.

- Inspecting the printed wads for any defects

- Making adjustments to the printing process as needed

4. Health and Safety

Wad Printing Machine Operators are responsible for following all safety procedures and regulations.

- Wearing appropriate safety gear

- Keeping the work area clean and organized

Interview Tips

Preparing for an interview for a Wad Printing Machine Operator position can be daunting, but following these tips can help candidates increase their chances of success.

1. Research the Position

Before the interview, candidates should thoroughly research the Wad Printing Machine Operator position and the company they are applying to. This will help them understand the specific requirements of the role and the company’s culture.

- Read the job description carefully

- Visit the company’s website to learn about their products and services

2. Practice Answering Common Interview Questions

Candidates should practice answering common interview questions related to their skills, experience, and knowledge. This will help them feel more confident and prepared during the interview.

- Why are you interested in this position?

- What is your experience operating printing machines?

- How do you ensure the quality of the printed wads?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that candidates are engaged and interested in the position. It also gives them an opportunity to learn more about the role and the company.

- What are the company’s growth plans?

- What are the opportunities for professional development?

4. Dress Professionally and Arrive on Time

First impressions matter, so candidates should dress professionally and arrive on time for the interview. This shows that they are respectful of the interviewer’s time and that they take the interview seriously.

- Wear clean and pressed clothing

- Arrive 10-15 minutes early for the interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wad Printing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.