Feeling lost in a sea of interview questions? Landed that dream interview for Wafer Fabrication Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wafer Fabrication Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

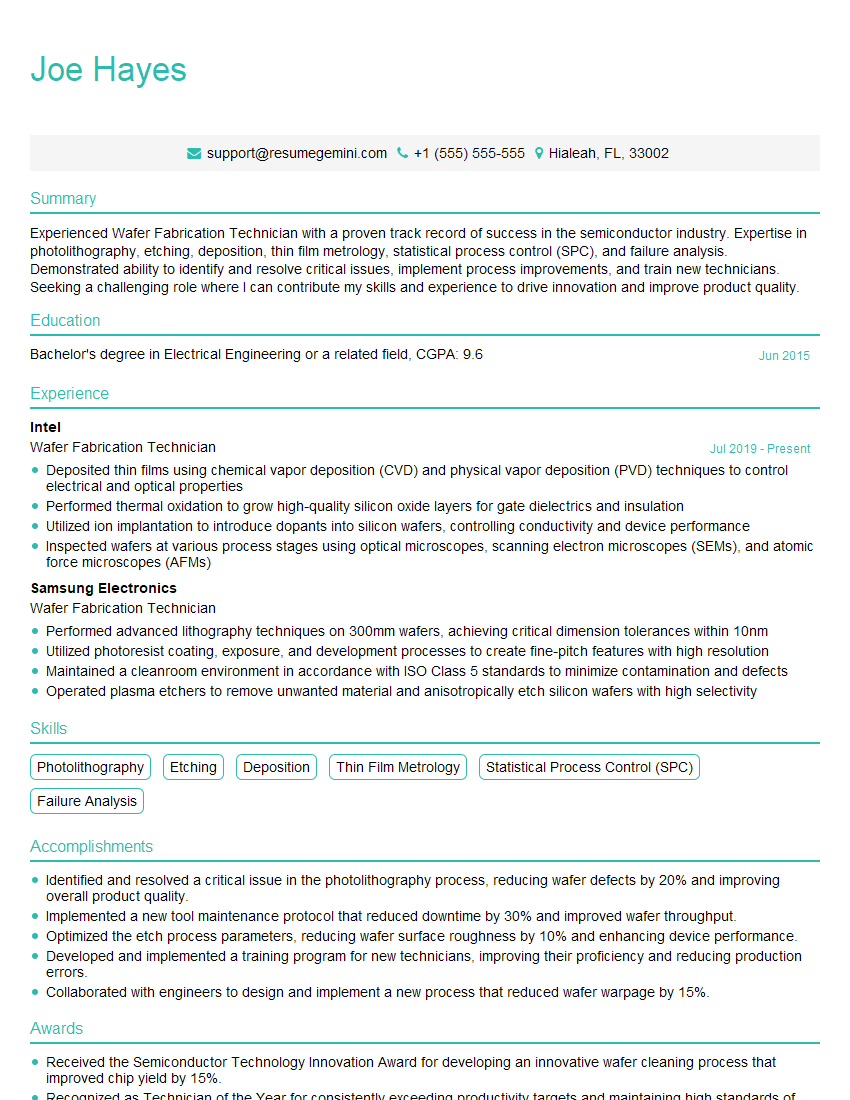

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wafer Fabrication Technician

1. Explain the process of photolithography used in wafer fabrication?

Photolithography is a critical process in wafer fabrication that involves transferring a desired circuit pattern onto a silicon wafer. Here’s an outline of the process:

- Photoresist Application: A layer of photoresist, a light-sensitive material, is applied to the wafer’s surface.

- Exposure: The photoresist is exposed to ultraviolet light through a photomask, a transparent film with the circuit pattern.

- Development: The exposed areas of the photoresist are dissolved in a developer solution, leaving the unexposed areas intact.

- Pattern Transfer: The remaining photoresist acts as a mask during etching or deposition processes, transferring the circuit pattern onto the wafer.

2. Describe the different types of etching techniques used in wafer fabrication?

Wet Etching

- Involves using a liquid etchant to dissolve and remove material from the wafer.

- Often used for isotropic etching (etching in all directions).

Dry Etching

- Uses a plasma or reactive ion beam to remove material from the wafer.

- Can achieve anisotropic etching (etching in a specific direction).

3. Explain the purpose and advantages of chemical vapor deposition (CVD) in wafer fabrication?

Chemical vapor deposition (CVD) is a thin-film deposition technique that involves depositing a material onto the wafer’s surface from a gas-phase precursor. Advantages include:

- Conformal coverage, even on complex structures.

- High purity and uniformity of deposited films.

- Ability to deposit a wide range of materials, including metals, dielectrics, and semiconductors.

4. How do you handle and prevent electrostatic discharge (ESD) during wafer fabrication?

ESD can damage sensitive electronic components, so it’s crucial to handle and prevent it during wafer fabrication:

- Use ESD-safe materials and equipment.

- Ground all equipment and personnel.

- Wear ESD-protective clothing, such as anti-static coveralls, gloves, and wrist straps.

- Handle wafers carefully to avoid contact with charged surfaces.

5. Describe the quality control measures employed in wafer fabrication to ensure product reliability?

Quality control is vital in wafer fabrication to maintain product reliability:

- Wafer Inspection: Inspecting wafers at various stages of fabrication for defects, contamination, and pattern fidelity.

- Electrical Testing: Performing electrical tests on wafers to verify functionality and performance.

- Statistical Process Control: Monitoring and analyzing production processes to identify and eliminate potential problems.

- Failure Analysis: Investigating failed wafers to determine root causes and improve processes.

6. How do you troubleshoot and resolve common defects encountered during wafer fabrication?

Troubleshooting and resolving defects is crucial in wafer fabrication:

- Identify the defect type and possible causes.

- Review process parameters and identify potential deviations.

- Inspect the wafer using microscopes and other tools to locate the defect.

- Implement corrective actions based on the identified root cause.

- Verify the effectiveness of corrective actions and make adjustments as needed.

7. Explain the importance of cleanroom environment in wafer fabrication?

A cleanroom environment is crucial in wafer fabrication to prevent contamination:

- Controls the presence of airborne particles, dust, and other contaminants that can damage wafers.

- Maintains temperature, humidity, and pressure levels within specified limits.

- Protects wafers from electrostatic discharge and other hazards.

8. Describe the role of robotics and automation in modern wafer fabrication facilities?

- Increases productivity and efficiency by automating repetitive tasks.

- Improves precision and accuracy, reducing the risk of human error.

- Enables continuous operation, allowing for increased production capacity.

- Reduces labor costs and improves overall cost-effectiveness.

9. Discuss the challenges and opportunities in the field of wafer fabrication?

Challenges

- Advancements in technology leading to more complex and sophisticated devices.

- Increasing demand for smaller and more powerful chips.

- Need for cost-effective and environmentally sustainable manufacturing processes.

Opportunities

- Development of new materials and fabrication techniques.

- Growth in the semiconductor industry due to increasing demand for electronics.

- Opportunities for research and innovation in advanced manufacturing technologies.

10. How do you stay updated with the latest technological advancements in wafer fabrication?

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Network with professionals in the field.

- Participate in training programs and certifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wafer Fabrication Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wafer Fabrication Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wafer Fabrication Technician is a skilled professional responsible for the manufacturing of semiconductor wafers, the essential components of integrated circuits found in various electronic devices. Their key responsibilities include:

1. Wafer Preparation and Cleaning

Preparing and cleaning the silicon wafers by removing impurities and defects to ensure a clean and contaminant-free surface for subsequent processing.

- Inspect wafers for defects and surface imperfections

- Clean wafers using chemical and mechanical techniques

2. Photolithography and Etching

Applying photoresist to wafers and utilizing ultraviolet light to create patterns on the surface, which are then etched into the wafer to form desired circuit structures.

- Apply photoresist to wafers using spin coating or other techniques

- Expose wafers to ultraviolet light using photolithography equipment

- Develop exposed wafers to create desired patterns

- Etch wafers using chemical or plasma etching techniques to remove unwanted material and form circuit structures

3. Thin Film Deposition

Depositing thin layers of materials onto wafers using techniques such as chemical vapor deposition (CVD) or physical vapor deposition (PVD) to create specific electrical and functional properties.

- Prepare wafers for deposition by cleaning and activating surfaces

- Operate deposition equipment to deposit thin films of materials with precise thickness and composition

- Monitor and control deposition parameters to ensure film quality and uniformity

4. Metrology and Testing

Conducting measurements and tests on wafers throughout the fabrication process to ensure adherence to specifications and identify any defects or contamination.

- Perform electrical measurements to assess circuit functionality

- Use microscopes and other instruments to inspect wafers for defects

- Analyze test results and identify areas for improvement in the fabrication process

5. Equipment Maintenance and Calibration

Maintaining and calibrating wafer fabrication equipment to ensure optimal performance and prevent contamination or defects in wafers.

- Inspect and clean equipment regularly

- Perform preventive maintenance tasks

- Calibrate equipment according to manufacturer’s specifications

- Troubleshoot and resolve equipment issues

Interview Tips

To ace an interview for a Wafer Fabrication Technician position, candidates should prepare thoroughly and demonstrate their technical expertise and practical skills.

1. Research the Company and Role

Familiarize yourself with the company’s background, mission, and products. Research the specific responsibilities of the Wafer Fabrication Technician role and identify the key skills and qualifications required.

2. Highlight Technical Skills and Experience

Emphasize your technical skills in wafer fabrication, including photolithography, etching, thin film deposition, metrology, and testing. Provide concrete examples of your experience and achievements in these areas.

3. Showcase Cleanroom Experience

Cleanroom experience is essential for Wafer Fabrication Technicians. Highlight your familiarity with cleanroom procedures, safety protocols, and the use of personal protective equipment (PPE).

4. Prepare for Questions about Equipment and Processes

Interviewers may ask specific questions about wafer fabrication equipment and processes. Be prepared to discuss your understanding of different types of equipment, deposition techniques, and quality control procedures.

5. Practice STAR Method

Use the STAR method (Situation, Task, Action, Result) when answering behavioral questions. Provide detailed examples of how you handled specific situations, the actions you took, and the positive outcomes you achieved.

6. Emphasize Safety, Quality, and Attention to Detail

Safety, quality, and attention to detail are paramount in wafer fabrication. Highlight your commitment to these aspects and provide examples of how you ensure accuracy and adherence to specifications.

7. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions about the company’s technology, innovation, or future plans to show your enthusiasm and curiosity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wafer Fabrication Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wafer Fabrication Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.