Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wafer Line Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

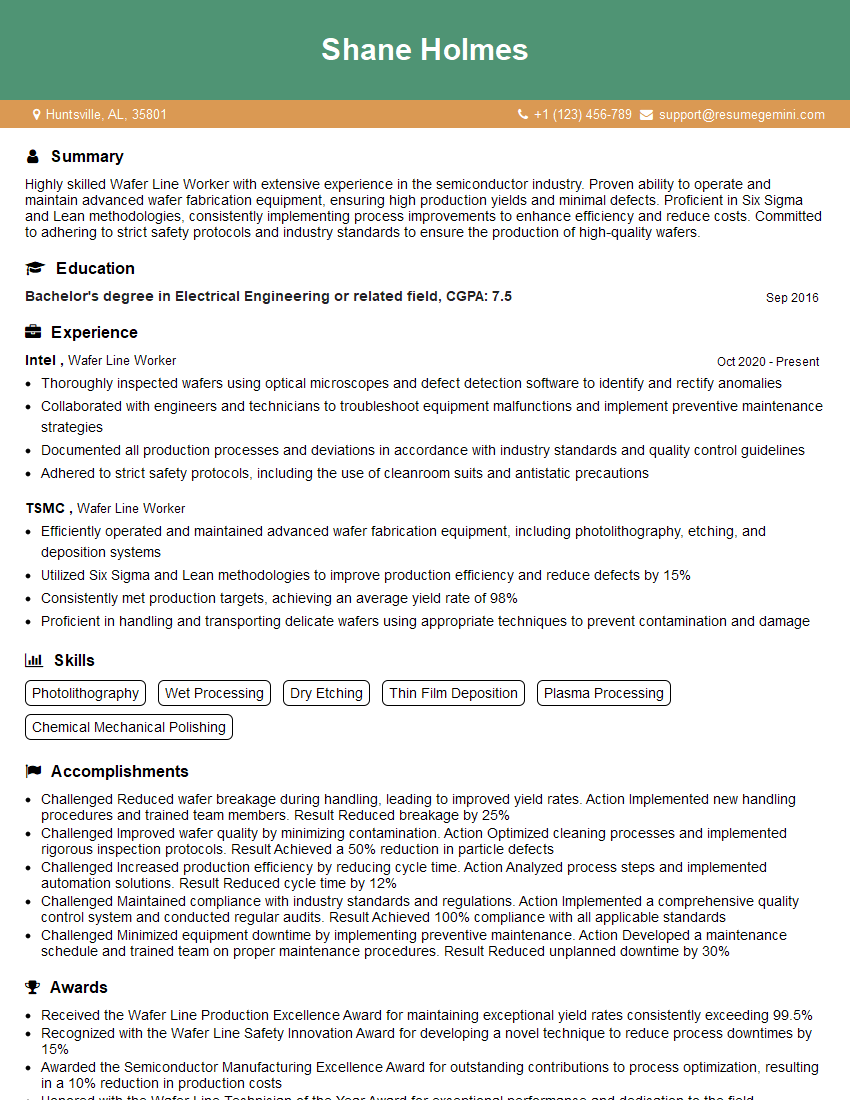

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wafer Line Worker

1. Describe the key responsibilities of a Wafer Line Worker?

As a Wafer Line Worker, my primary responsibilities would include:

- Performing wafer preparation, handling, and processing tasks within the cleanroom environment.

- Operating and monitoring wafer processing equipment, such as photolithography, etching, and deposition systems.

- Inspecting and identifying defects on wafers and implementing corrective actions.

- Adhering to strict quality control standards and maintaining a clean and organized work area.

2. How do you handle and prevent contamination during wafer handling?

Maintaining a Cleanroom Environment

- Wear appropriate cleanroom attire and maintain aseptic techniques.

- Use cleanroom-approved materials and equipment to minimize particle generation.

Wafer Handling Procedures

- Use non-scratching tweezers or vacuum tools to handle wafers.

- Avoid touching the active surface of the wafer.

- Store and transport wafers in anti-static containers.

Equipment Maintenance

- Regularly clean and maintain wafer processing equipment to prevent contamination.

- Use particle-free gases and chemicals in all processes.

3. Explain the photolithography process and its importance in wafer fabrication?

Photolithography is a critical process in wafer fabrication that involves transferring a design pattern onto the wafer’s surface.

- Preparation: A photoresist is applied to the wafer.

- Exposure: The wafer is exposed to ultraviolet (UV) light through a mask containing the desired pattern.

- Development: The exposed areas of the photoresist are removed, leaving the desired pattern on the wafer.

- Importance: Photolithography allows for precise patterning of transistors and interconnects, determining the electrical characteristics of the integrated circuits.

4. What are the different types of etching techniques used in wafer fabrication, and how do they differ?

- Wet Etching: Uses liquid chemicals to dissolve exposed areas of the wafer.

- Dry Etching: Uses plasma or reactive gases to remove material through chemical reactions.

- Isotropic Etching: Etches in all directions, resulting in undercuts.

- Anisotropic Etching: Etches in a preferred direction, creating vertical sidewalls.

5. How do you perform wafer inspection and identify defects?

- Visual Inspection: Using a microscope to examine wafers for scratches, particles, or other surface defects.

- Electrical Testing: Using probes or test equipment to check for electrical shorts, opens, or other malfunctions.

- Automated Inspection: Using machines with cameras and sensors to detect defects.

6. Describe the role of cleanroom protocols in maintaining wafer quality?

- Minimize Contamination: Restricting access, wearing cleanroom suits, and using filtered air helps prevent particle contamination.

- Control Temperature and Humidity: Maintaining optimal conditions ensures proper resist adhesion and etching.

- Safety: Cleanroom protocols protect workers from hazardous chemicals and electrical hazards.

7. How do you ensure the accuracy and precision of wafer processing equipment?

- Regular Calibration: Using certified standards to calibrate equipment to maintain accuracy.

- Preventive Maintenance: Performing scheduled inspections and repairs to prevent malfunctions.

- Process Control: Monitoring process parameters and making adjustments to optimize performance.

8. What safety precautions are necessary when working with chemicals and gases in the wafer fabrication area?

- Proper Attire: Wearing gloves, masks, and protective clothing to prevent exposure.

- Handling Procedures: Following safe handling guidelines for chemicals and gases.

- Emergency Response: Knowing the location of safety equipment and response protocols.

9. How do you stay up-to-date with advancements in wafer fabrication technology?

- Industry Conferences: Attending conferences and workshops to learn about new techniques and equipment.

- Technical Literature: Reading journals and technical papers to stay informed about developments.

- Online Resources: Utilizing online forums and websites to share knowledge and learn from others.

10. What is your understanding of the semiconductor industry’s quality standards, such as ISO 9001 and AS9100?

- ISO 9001: Focuses on quality management systems, process improvement, and customer satisfaction.

- AS9100: Specific to the aerospace industry, emphasizing safety, reliability, and traceability.

- Compliance: Adherence to these standards ensures high-quality products, customer trust, and market acceptance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wafer Line Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wafer Line Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wafer Line Workers play a crucial role in the semiconductor industry, ensuring the smooth and efficient production of wafers. Their key responsibilities encompass diverse aspects of wafer fabrication, including:

1. Equipment Operation

Operate and maintain semiconductor processing equipment, such as photolithography, etching, and deposition systems.

- Monitor and control process parameters to meet specifications.

- Identify and troubleshoot equipment malfunctions.

2. Wafer Handling

Handle wafers with precision and care, minimizing defects and contamination.

- Load and unload wafers into processing equipment.

- Inspect wafers for defects using microscopes and automated inspection systems.

3. Process Control

Monitor and control process variables to ensure product quality.

- Collect and analyze data on process parameters.

- Identify and implement process improvements to enhance yield and reduce defects.

4. Safety and Compliance

Adhere to safety regulations and industry standards to maintain a safe and compliant work environment.

- Wear appropriate personal protective equipment.

- Follow proper handling and storage procedures for chemicals and hazardous materials.

Interview Tips

To ace the interview for a Wafer Line Worker position, it is essential to prepare thoroughly and present yourself as a skilled and motivated candidate. Here are some tips to enhance your chances of success:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company and the semiconductor industry. Familiarize yourself with their products, services, and recent developments.

- Visit the company’s website and LinkedIn page.

- Read industry publications and news articles.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments and provide specific examples to demonstrate your capabilities.

- Showcase your proficiency in operating semiconductor processing equipment.

- Discuss your experience in wafer handling, process control, and safety.

3. Prepare for Technical Questions

Expect technical questions related to semiconductor processing, equipment operation, and process control. Review basic concepts and be ready to discuss your understanding of the industry.

- Brush up on photolithography, etching, and deposition processes.

- Practice troubleshooting equipment malfunctions.

4. Show Enthusiasm and Motivation

Convey your passion for the semiconductor industry and your motivation to contribute to the company’s success. Express your interest in learning and growing in the field.

- Explain why you are interested in the Wafer Line Worker role.

- Share your career aspirations and how the position aligns with your goals.

5. Practice Your Answers

Prepare and practice your answers to common interview questions. This will help you articulate your thoughts clearly and confidently.

- Rehearse questions related to your skills, experience, and motivations.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wafer Line Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!