Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wafer Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wafer Machine Operator so you can tailor your answers to impress potential employers.

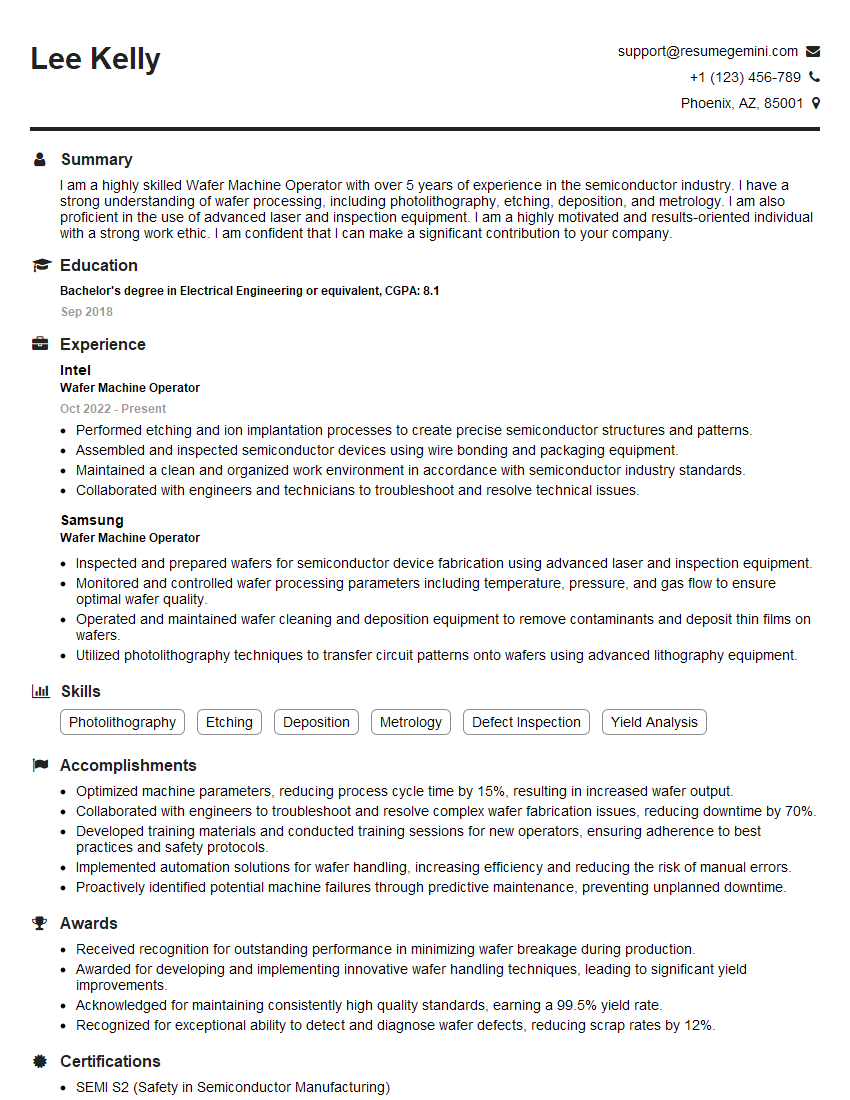

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wafer Machine Operator

1. Explain the steps involved in operating a wafer machine?

- Load wafers: Load the wafers into the machine’s cassette and place it into the loading port.

- Select recipe: Select the appropriate recipe for the process to be performed on the wafers.

- Start process: Initiate the process by pressing the start button.

- Monitor process: Monitor the process parameters and make adjustments as necessary.

- Unload wafers: Once the process is complete, unload the wafers from the machine’s cassette.

2. What are the different types of wafer machines?

- Lithography machines: Used to pattern wafers with the desired circuit design.

- Etching machines: Used to remove unwanted material from wafers.

- Deposition machines: Used to deposit thin films onto wafers.

- Metrology machines: Used to measure and inspect wafers.

- Packaging machines: Used to encapsulate wafers into packages.

3. What are the key safety procedures that must be followed when operating a wafer machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Do not operate the machine if it is not properly grounded.

- Keep the machine area clean and free of debris.

- Never touch the wafers or the machine’s components while it is in operation.

- Follow all manufacturer’s instructions for safe operation.

4. What are the common problems that can occur when operating a wafer machine, and how can they be resolved?

- Wafer breakage: Caused by mishandling or improper loading of wafers. Can be resolved by carefully handling wafers and ensuring they are properly loaded into the machine’s cassette.

- Process errors: Caused by incorrect recipe selection or process parameters. Can be resolved by verifying the recipe and process parameters and making necessary adjustments.

- Equipment malfunctions: Caused by mechanical or electrical failures. Can be resolved by troubleshooting the machine and contacting a qualified technician if necessary.

5. What are the quality control procedures that must be followed when operating a wafer machine?

- Inspect wafers: Inspect wafers for defects before loading them into the machine.

- Monitor process parameters: Monitor the process parameters closely to ensure they are within specifications.

- Inspect wafers after processing: Inspect wafers for defects after processing to ensure they meet quality standards.

- Maintain records: Maintain records of all wafer processing performed, including the recipe, process parameters, and inspection results.

6. What is the role of maintenance in wafer machine operation?

- Preventative maintenance: Regular maintenance is essential to prevent equipment malfunctions and ensure optimal performance.

- Corrective maintenance: In the event of a malfunction, prompt corrective maintenance is necessary to restore the machine to working order.

- Calibration: Periodic calibration of the machine’s sensors and gauges is necessary to ensure accurate measurements and process control.

7. What is the importance of documentation in wafer machine operation?

- Process traceability: Documentation allows for the tracking of wafers through the manufacturing process, enabling the identification of any issues that may arise.

- Quality control: Documentation provides evidence of compliance with quality standards and enables the identification of areas for improvement.

- Training: Documentation can serve as a training tool for new and experienced operators, ensuring consistent operation and maintenance practices.

8. What are the different types of wafers used in semiconductor manufacturing?

- Silicon wafers: The most common type of wafer, used in the fabrication of integrated circuits.

- Gallium arsenide (GaAs) wafers: Used in the fabrication of high-speed and optoelectronic devices.

- Indium phosphide (InP) wafers: Used in the fabrication of high-power and high-frequency devices.

9. What are the key performance indicators (KPIs) used to evaluate wafer machine performance?

- Throughput: The number of wafers processed per unit time.

- Yield: The percentage of wafers that meet quality standards.

- Uptime: The percentage of time that the machine is operational.

10. What are the emerging trends in wafer machine technology?

- Increased automation: The use of robots and other automated systems to reduce the need for manual labor.

- Improved precision and accuracy: The development of new technologies to enable more precise and accurate wafer processing.

- Increased use of artificial intelligence (AI): The use of AI to optimize process parameters and predict potential problems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wafer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wafer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Wafer Machine Operator, you will play a vital role in the semiconductor fabrication process, ensuring the smooth and efficient operation of wafer processing machines.

1. Wafer Handling and Processing

Your primary responsibility will involve handling and processing silicon wafers throughout various stages of production. You will be responsible for:

- Loading and unloading wafers into and out of machines

- Inspecting wafers for defects or contamination

- Performing cleaning and other preparatory steps as required

2. Machine Operation and Maintenance

You will be operating and maintaining a range of wafer processing machines. This includes:

- Monitoring machine parameters and making adjustments as needed

- Performing routine maintenance and troubleshooting minor issues

- Reporting any major problems or equipment failures promptly

3. Quality Control and Process Improvement

Ensuring the quality of wafers is crucial. You will be involved in:

- Conducting quality checks on wafers at various stages

- Maintaining detailed records of process parameters and results

- Participating in process improvement initiatives to enhance productivity

4. Safety and Compliance

Adhering to strict safety regulations is essential in this role. You will be responsible for:

- Following established safety procedures and wearing appropriate protective gear

- Maintaining a clean and organized work environment

- Complying with all applicable industry standards and regulations

Interview Tips

Preparing thoroughly for your interview is crucial. Here are some tips to help you ace the interview and secure the job:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific role. This will help you understand their business, culture, and the key responsibilities of the position. You can visit the company’s website, read industry news, and connect with current or former employees on LinkedIn.

2. Practice Your Answers

Common interview questions for Wafer Machine Operators often focus on technical skills, problem-solving abilities, and safety procedures. Prepare your answers to these questions by recalling specific examples from your experience that demonstrate your competence. Use the STAR method (Situation, Task, Action, Result) to structure your responses and provide clear, concise answers.

3. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate the impact of your contributions. For example, you could mention reducing production defects by a certain percentage or improving machine uptime by a specific amount.

4. Ask Thoughtful Questions

Asking thoughtful questions shows your interest in the position and the company. Prepare a few questions in advance about the following topics: company culture, growth opportunities, specific projects or technologies used, and any industry trends or challenges.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wafer Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.