Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wafer Polishing Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

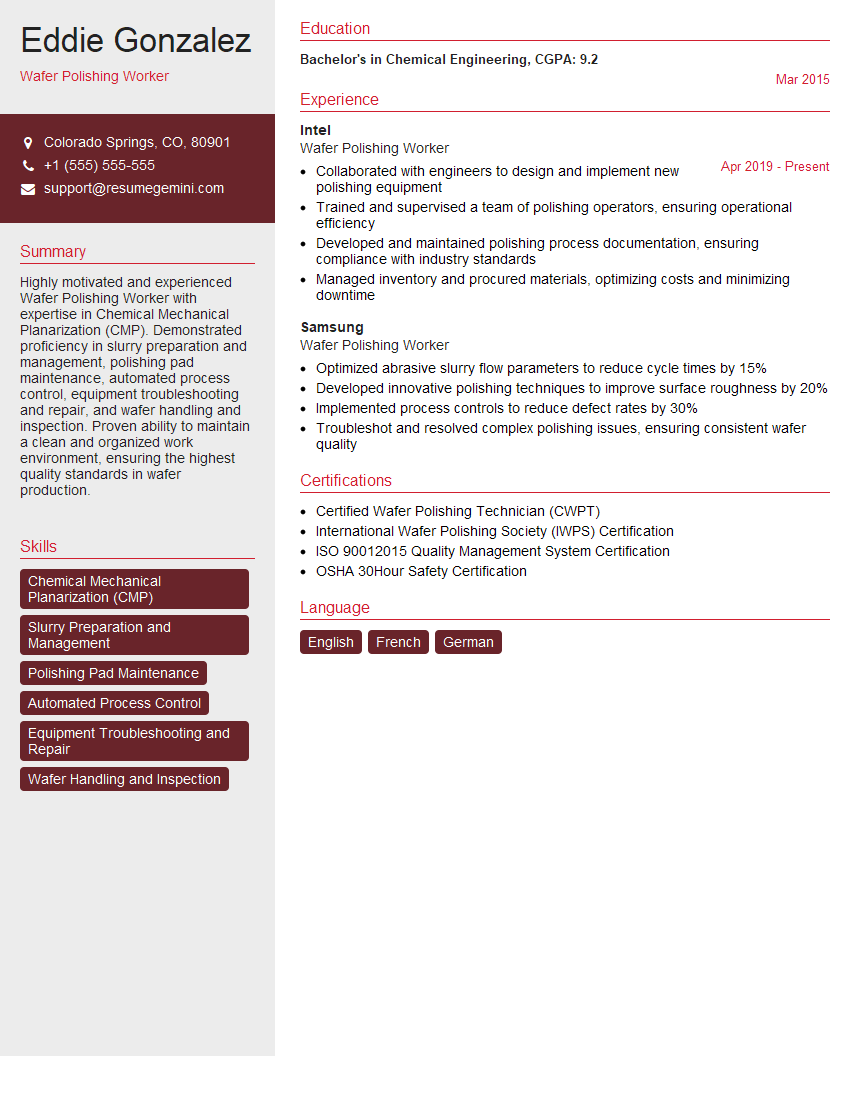

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wafer Polishing Worker

1. What are the key steps involved in the wafer polishing process?

- Prepare the wafer by cleaning and etching the surface, which removes contamination and creates a smooth surface for polishing.

- Mount the wafer onto a polishing pad, which is made of a material that is harder than the wafer.

- Apply a slurry to the polishing pad, which contains abrasive particles that are used to remove material from the wafer.

- Polish the wafer by moving it back and forth across the polishing pad under pressure.

- Remove the wafer from the polishing pad and clean it to remove any remaining slurry or debris.

- Inspect the wafer to ensure that it meets the required specifications for thickness, flatness, and surface finish.

2. What are the different types of polishing pads used in wafer polishing?

Diamond pads

- Diamond pads are the most common type of polishing pad used in wafer polishing.

- They are made of a metal or plastic base with diamond particles embedded in the surface.

- Diamond pads are very hard and durable, and they can be used to remove a large amount of material from the wafer.

Cerium oxide pads

- Cerium oxide pads are made of a ceramic material with cerium oxide particles embedded in the surface.

- Cerium oxide pads are less hard than diamond pads, and they are used to remove smaller amounts of material from the wafer.

- Cerium oxide pads are also used to polish the wafer to a high surface finish.

Silica pads

- Silica pads are made of a silicon dioxide material with silica particles embedded in the surface.

- Silica pads are very soft and flexible, and they are used to polish the wafer to a very high surface finish.

- Silica pads are also used to remove very small amounts of material from the wafer.

3. What are the different types of slurries used in wafer polishing?

- Diamond slurries are made of diamond particles suspended in a liquid.

- Diamond slurries are used to remove a large amount of material from the wafer.

- Cerium oxide slurries are made of cerium oxide particles suspended in a liquid.

- Cerium oxide slurries are used to remove smaller amounts of material from the wafer and to polish the wafer to a high surface finish.

- Silica slurries are made of silica particles suspended in a liquid.

- Silica slurries are used to polish the wafer to a very high surface finish and to remove very small amounts of material from the wafer.

4. What are the key factors that affect the quality of the polished wafer?

- The type of polishing pad used

- The type of slurry used

- The pressure applied to the wafer during polishing

- The speed at which the wafer is moved across the polishing pad

- The duration of the polishing process

- The temperature of the polishing process

5. What are the different types of defects that can occur during wafer polishing?

- Scratches: Scratches are caused by hard particles that are embedded in the polishing pad or the slurry.

- Dimples: Dimples are caused by soft particles that are embedded in the polishing pad or the slurry.

- Pits: Pits are caused by chemical etching of the wafer surface.

- Cracks: Cracks are caused by excessive pressure or temperature during the polishing process.

6. What are the different methods used to inspect polished wafers?

- Visual inspection: Visual inspection is used to identify scratches, dimples, and other defects that can be seen with the naked eye.

- Microscopic inspection: Microscopic inspection is used to identify defects that are too small to be seen with the naked eye.

- Electrical testing: Electrical testing is used to identify defects that affect the electrical properties of the wafer.

7. What are the key safety precautions that must be taken when working with wafers?

- Wafers are very thin and fragile, so they must be handled with care.

- Wafers can be sharp, so they should be handled with gloves.

- Wafers can be contaminated easily, so they should be handled in a clean environment.

- The chemicals used in wafer polishing can be hazardous, so they should be handled with care and disposed of properly.

8. What are the key challenges of wafer polishing?

- Achieving a high surface finish without damaging the wafer

- Removing all defects from the wafer

- Maintaining a consistent polishing process

- Keeping up with the latest advances in wafer polishing technology

9. What are the key trends in wafer polishing technology?

- The development of new polishing pads and slurries

- The use of new polishing techniques, such as chemical-mechanical polishing (CMP)

- The integration of wafer polishing into automated manufacturing processes

10. What are the key skills and qualifications required for a wafer polishing worker?

- A good understanding of the wafer polishing process

- Experience in working with wafers

- A strong attention to detail

- Good communication and teamwork skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wafer Polishing Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wafer Polishing Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wafer Polishing Worker is responsible for preparing and polishing silicon wafers used in the manufacturing of semiconductor devices. Their key responsibilities include:1. Wafer Preparation

Preparing wafers for polishing involves:

- Inspecting wafers for defects and ensuring their cleanliness.

- Mounting wafers onto polishing fixtures securely.

- Applying protective coatings to wafers before polishing.

2. Wafer Polishing

Polishing wafers involves operating polishing machines:

- Setting up and operating wafer polishing machines according to process specifications.

- Monitoring the polishing process and making adjustments to ensure optimal results.

- Maintaining a clean and organized work area, adhering to safety protocols.

3. Quality Control

Ensuring wafer quality involves:

- Inspecting polished wafers for defects and surface finish.

- Performing measurements and tests to verify wafer specifications.

- Documenting inspection results and maintaining quality records.

4. Equipment Maintenance

Maintaining polishing equipment involves:

- Cleaning and lubricating polishing machines regularly.

- Performing minor repairs and troubleshooting equipment issues.

- Collaborating with maintenance technicians for major repairs.

Interview Tips

Preparing for an interview for a Wafer Polishing Worker position requires both technical proficiency and a professional approach. Here are some tips to help you ace the interview:1. Research the Company and Position

Thoroughly research the company’s website, industry news, and social media pages. Understand their products, services, and company culture. Carefully review the job description to identify the specific skills and experience required for the role.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in wafer preparation, polishing, quality control, and equipment maintenance. Provide specific examples of your experience that demonstrate your proficiency in these areas. Quantify your accomplishments whenever possible, using specific metrics or data to showcase your impact.

3. Prepare for Technical Questions

Expect technical questions related to wafer polishing processes, equipment, and quality control standards. Be prepared to discuss your understanding of surface chemistry, polishing abrasives, and measurement techniques. Demonstrate your ability to troubleshoot common issues and suggest solutions.

4. Show Enthusiasm and Professionalism

Convey your passion for the semiconductor industry and your eagerness to contribute to the team. Dress professionally and arrive on time for the interview. Maintain eye contact, ask thoughtful questions, and actively listen to the interviewer’s questions and responses.

5. Practice and Seek Feedback

Practice answering common interview questions aloud. Ask a friend or family member to conduct a mock interview and provide feedback on your answers. This will help you gain confidence and refine your delivery. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

By following these tips and preparing diligently, you can increase your chances of making a positive impression and securing the Wafer Polishing Worker position.Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wafer Polishing Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wafer Polishing Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.