Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wafer Substrate Tester interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wafer Substrate Tester so you can tailor your answers to impress potential employers.

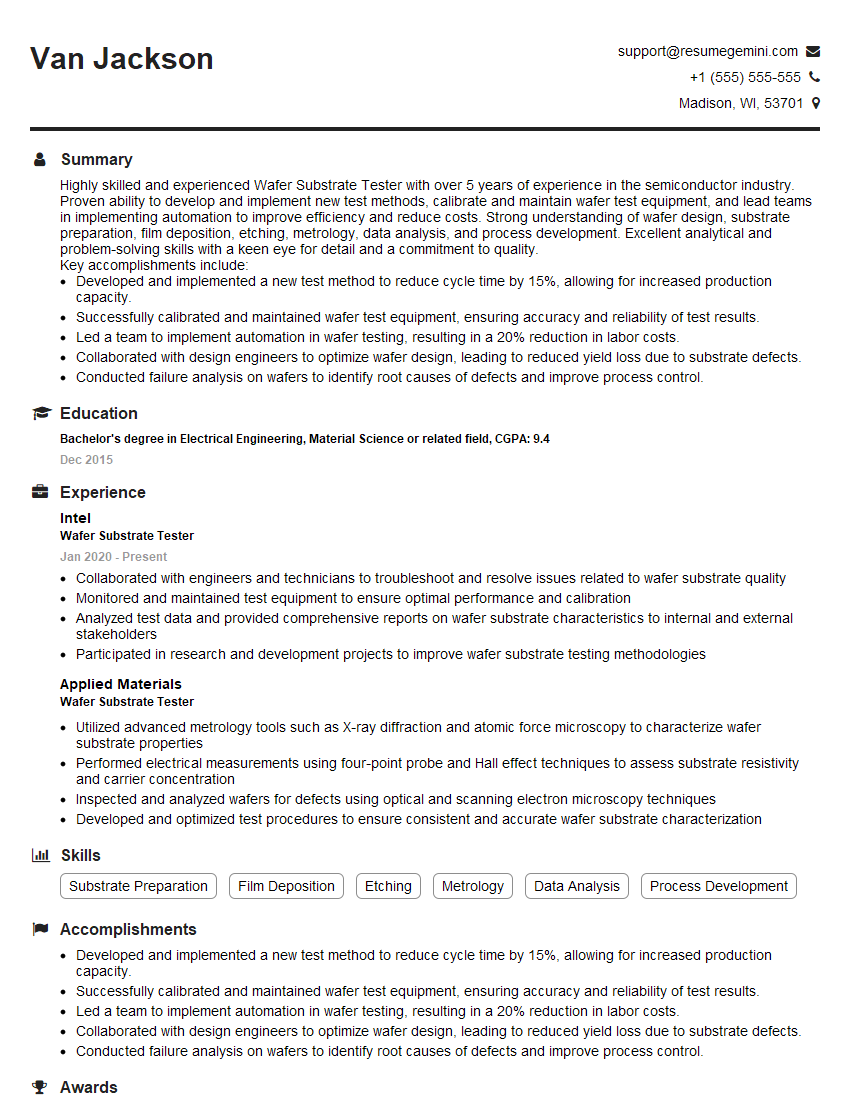

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wafer Substrate Tester

1. Explain the different types of wafer substrate testing methods?

There are various wafer substrate testing methods, including:

- Bow and warp measurement: Determines the curvature and deformation of the wafer.

- Thickness measurement: Measures the thickness of the wafer at various points.

- Flatness measurement: Evaluates the flatness of the wafer surface.

- Particle and defect inspection: Identifies and quantifies particles and defects on the wafer surface.

- Resistivity measurement: Measures the electrical resistivity of the wafer material.

- Crystalline orientation measurement: Determines the crystallographic orientation of the wafer.

- Surface roughness measurement: Analyzes the roughness of the wafer surface.

- Film thickness measurement: Measures the thickness of any deposited films on the wafer.

2. Describe the key parameters to consider when selecting a wafer substrate tester?

Factors to consider:

- Measurement accuracy and precision: The tester’s ability to provide accurate and repeatable measurements.

- Measurement range: The range of values that the tester can measure.

- Measurement speed: The time required to perform a measurement.

- Automation capabilities: The level of automation the tester offers, such as automatic wafer handling and data analysis.

- Software and data management: The user-friendliness and capabilities of the software for data analysis, reporting, and control.

- Maintenance and support: The availability of technical support and spare parts.

3. How do you ensure the accuracy and reliability of wafer substrate test results?

To ensure accuracy and reliability:

- Calibration and verification: Regularly calibrate and verify the tester using traceable reference standards.

- Environmental control: Maintain a controlled environment (e.g., temperature, humidity) to minimize external influences.

- Operator training: Ensure operators are properly trained and follow standardized testing procedures.

- Data analysis and interpretation: Analyze test results carefully and interpret them correctly using appropriate statistical methods.

- Quality control: Implement quality control procedures to ensure consistent and reliable results.

- Round-robin testing: Participate in round-robin testing programs to compare results with other laboratories.

4. Discuss the challenges associated with testing wafers for advanced semiconductor devices?

Challenges for advanced semiconductor devices:

- Smaller feature sizes: Testing becomes more difficult as feature sizes on wafers decrease.

- Complex device structures: Advanced devices have multiple layers and complex structures, making testing more challenging.

- Increased sensitivity to defects: Smaller feature sizes and complex structures increase the sensitivity to defects, requiring more rigorous testing.

- Need for high-throughput testing: To meet production demands, high-throughput testing with minimal downtime is essential.

- Integration with other test equipment: Wafer substrate testing often needs to be integrated with other test equipment for comprehensive device characterization.

5. Explain the role of automation in wafer substrate testing?

Benefits of automation:

- Improved efficiency: Automation reduces manual labor and increases throughput.

- Reduced human error: Automated systems minimize the risk of human error, leading to more reliable results.

- Enhanced data management: Automated systems can efficiently collect, store, and analyze large amounts of data.

- Increased flexibility: Automated systems can be easily reconfigured to accommodate different test setups.

- Cost reduction: Automation can reduce labor costs and increase productivity.

6. Describe the different types of defect detection techniques used in wafer substrate testing?

- Optical inspection: Uses light sources and cameras to detect defects on the wafer surface.

- Electrical testing: Applies electrical signals to the wafer to identify electrical defects.

- Acoustic testing: Uses sound waves to detect defects in the wafer material.

- X-ray inspection: Uses X-rays to penetrate the wafer and detect internal defects.

- Laser scanning: Uses lasers to scan the wafer surface and detect defects.

7. Discuss the importance of wafer substrate testing in semiconductor manufacturing?

Importance of testing:

- Quality control: Ensures that wafers meet specified quality standards.

- Process monitoring: Helps identify and control process variations.

- Yield improvement: Identifies and eliminates defects that can lead to yield loss.

- Failure analysis: Facilitates the analysis of device failures to determine root causes.

- Research and development: Supports the development and optimization of new wafer substrates and manufacturing processes.

8. Describe the typical workflow for wafer substrate testing?

Workflow steps:

- Sample preparation: Prepare the wafer for testing (e.g., cleaning, etching).

- Test setup: Configure the tester according to the required test parameters.

- Data collection: Perform the test and collect data.

- Data analysis: Analyze the test results to identify any defects or deviations.

- Report generation: Generate a report summarizing the test results.

9. How do you handle and resolve common problems encountered during wafer substrate testing?

Problem-solving approach:

- Identify the problem: Determine the specific issue or deviation observed during testing.

- Analyze the cause: Investigate potential causes, such as equipment malfunction, sample preparation errors, or environmental factors.

- Implement solutions: Identify and implement appropriate solutions to address the root cause.

- Verify results: Perform additional tests to verify the effectiveness of the implemented solutions.

- Document and improve: Document the problem, its cause, and the solution for future reference and process improvement.

10. Stay updated with the latest advancements in wafer substrate testing technology?

- Attend industry conferences and workshops: Participate in events to learn about new technologies and research.

- Read technical journals and literature: Stay informed about recent publications and advancements in the field.

- Network with experts: Connect with researchers, engineers, and industry professionals to exchange knowledge and insights.

- Collaborate with equipment manufacturers: Engage with equipment manufacturers to learn about new developments and potential applications.

- Conduct research and development: Engage in research activities to explore new testing techniques and methodologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wafer Substrate Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wafer Substrate Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wafer Substrate Testers are responsible for conducting tests on wafer substrates to ensure their quality and reliability. Their key responsibilities include:

1. Substrate Evaluation

Evaluate the physical and chemical properties of wafer substrates, such as thickness, resistivity, and surface roughness.

2. Test Development

Develop and optimize test methods to assess the performance of wafer substrates.

3. Equipment Operation

Operate and maintain specialized testing equipment, such as atomic force microscopes and scanning electron microscopes.

4. Data Analysis

Analyze and interpret test results to determine the quality and reliability of wafer substrates.

5. Process Improvement

Identify areas for process improvement and develop strategies to enhance the quality and efficiency of testing.

Interview Tips

To ace the interview for a Wafer Substrate Tester position, candidates should consider the following tips:

1. Technical Expertise

Demonstrate strong technical knowledge in semiconductor materials, testing methodologies, and equipment.

2. Analytical Skills

Highlight your analytical skills and ability to interpret complex data to identify trends and make informed decisions.

3. Problem-Solving

Provide examples of how you have successfully solved problems related to wafer substrate testing and quality control.

4. Communication Skills

Emphasize your ability to communicate technical information effectively to both technical and non-technical audiences.

5. Industry Knowledge

Stay up-to-date on the latest industry trends and advancements in wafer substrate testing.

6. Example Outline

When answering interview questions, use the STAR method (Situation, Task, Action, Result) to provide clear and concise responses:

- Situation: Describe the context or problem you faced.

- Task: Explain the specific task or responsibility you were assigned.

- Action: Detail the steps you took to complete the task.

- Result: Quantify the outcomes or impact of your actions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wafer Substrate Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!