Are you gearing up for an interview for a Wagon Drill Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wagon Drill Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

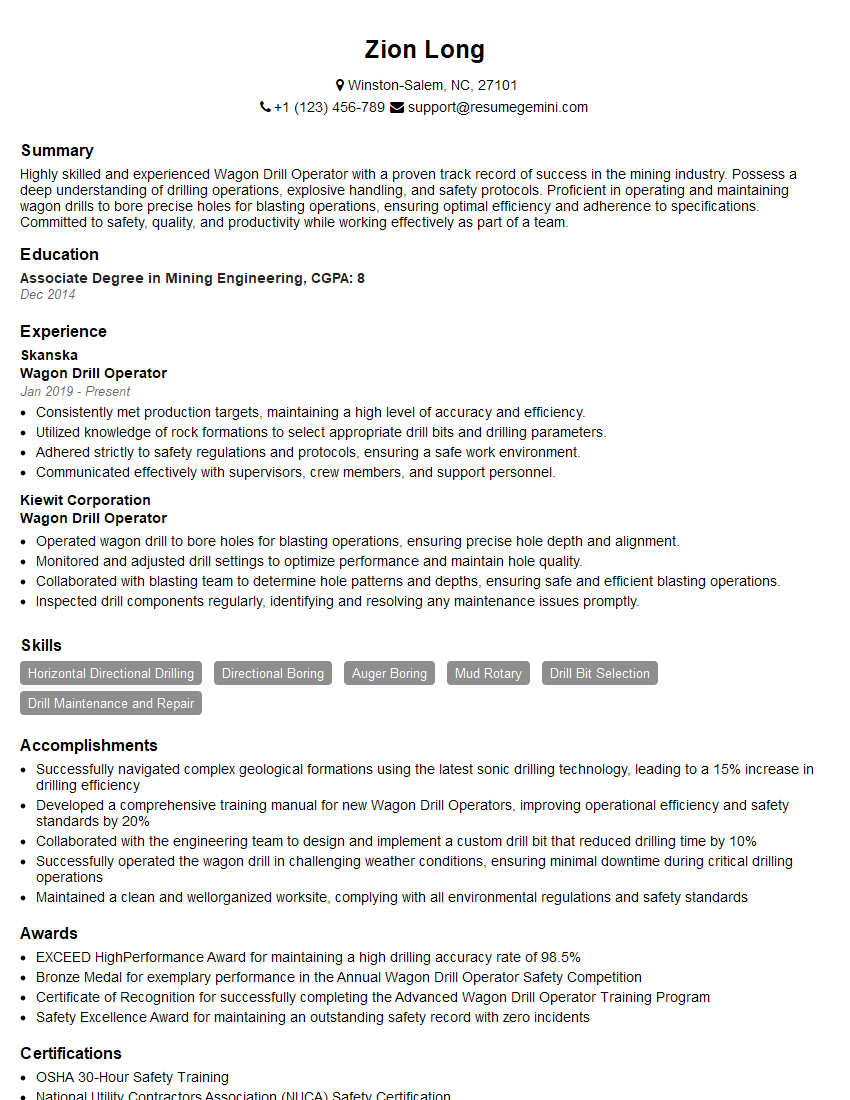

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wagon Drill Operator

1. Explain the procedure for setting up and calibrating a wagon drill?

The procedure for setting up and calibrating a wagon drill involves several steps, ensuring accuracy and optimal performance:

- Site Preparation: Select a level and stable location for the drill, considering factors such as ground conditions and proximity to the work area.

- Equipment Assembly: Assemble the drill components, including the mast, boom, and drill head, according to the manufacturer’s instructions.

- Leveling and Alignment: Use a level to ensure the drill is level both longitudinally and laterally. Adjust the stabilizers to provide a stable base.

- Mast Adjustment: Position the mast at the desired drilling angle and extend it to the required height, ensuring the boom is level.

- Drill Head Calibration: Calibrate the drill head to the specified drilling parameters, including rotation speed, feed rate, and penetration depth.

- Test Drilling: Perform a test drilling operation to verify the accuracy of the calibration and make any necessary adjustments.

2. Describe the different types of drill bits used for wagon drills and their applications

Wagon drills utilize various types of drill bits, each designed for specific drilling conditions and applications:

a) Tricone Bits

- General-purpose bits suitable for most drilling applications

- Feature three rotating cones with tungsten carbide inserts

b) Roller Cone Bits

- Designed for hard and abrasive formations

- Have numerous tungsten carbide studded cones that crush and break the rock

c) PDC (Polycrystalline Diamond Compact) Bits

- Highly efficient bits used for extremely hard formations

- Feature diamond-impregnated inserts that provide exceptional wear resistance

3. Explain the principles of percussive drilling and its advantages in rock excavation

Percussive drilling employs a hammering action to break down rock formations:

- Principle: A drill bit is repeatedly raised and dropped or rotated and hammered, creating impact forces on the rock.

- Advantages:

- High penetration rates in hard and abrasive rock

- Effective in formations with high compressive strength

- Produces clean and precise holes

4. Discuss the importance of ground support when operating a wagon drill

Ground support measures are crucial in ensuring the safety and stability of the work area during wagon drilling operations:

- Rock Bolting: Installing rock bolts to reinforce and stabilize the rock mass, preventing roof falls and other hazards.

- Shotcrete: Applying a layer of concrete to the rock surface to reinforce it and provide additional support.

- Wire Mesh: Using wire mesh to hold shotcrete in place and provide additional reinforcement.

- Monitoring: Regularly monitoring the work area for signs of ground movement or instability and taking appropriate action.

5. Explain the role of drilling fluids in wagon drilling operations

Drilling fluids play a vital role in wagon drilling operations by:

- Cooling and Lubricating: Removing heat generated by the drilling process and reducing friction between the drill bit and formation.

- Removing Cuttings: Carrying rock cuttings away from the drill bit and hole, preventing clogging and ensuring efficient drilling.

- Controlling Formation Pressure: Maintaining hydrostatic pressure in the hole to prevent fluid loss or blowouts.

6. Describe the safety precautions that must be taken when operating a wagon drill

Operating a wagon drill requires strict adherence to safety precautions:

- Training and Certification: Ensure proper training and certification of operators.

- Protective Gear: Wear appropriate protective gear, including hard hats, safety glasses, earplugs, and gloves.

- Ground Conditions Assessment: Conduct thorough ground conditions assessments and take appropriate ground support measures.

- Drill Inspection and Maintenance: Regularly inspect and maintain the drill to ensure safe operation.

- Emergency Procedures: Establish and communicate clear emergency procedures and evacuation plans.

7. Explain the importance of planning and layout for wagon drilling operations

Effective planning and layout are essential for successful wagon drilling operations:

- Drill Pattern Design: Designing an optimal drill pattern to achieve the desired blast results.

- Site Layout: Planning the layout of the work area, including drill setup locations, access roads, and spoil disposal areas.

- Environmental Considerations: Identifying and mitigating potential environmental impacts.

- Communication and Coordination: Establishing clear communication channels and coordinating with other teams involved in the operation.

8. Discuss the different methods used to measure and evaluate drilling performance

Drilling performance is measured and evaluated using various methods:

- Penetration Rate: The rate at which the drill bit advances into the rock, typically measured in meters per hour.

- Drilling Time: The total time taken to complete a specific drilling task.

- Drill Bit Wear: The condition and wear of the drill bit, which affects drilling efficiency and overall performance.

- Hole Quality: The accuracy, diameter, and smoothness of the drilled holes.

9. Describe the maintenance procedures recommended for wagon drills

Regular maintenance is crucial for efficient and safe operation of wagon drills:

- Daily Inspections: Visual inspections for leaks, loose connections, and any signs of damage.

- Weekly Maintenance: Lubricating moving parts, inspecting and cleaning filters, and checking fluid levels.

- Monthly Maintenance: More comprehensive inspections, including drill head and hydraulic system checks, and minor repairs as needed.

- Annual Maintenance: Major overhauls, involving component replacements and thorough inspections to ensure overall performance.

10. Discuss the potential challenges and risks associated with wagon drilling operations and mitigation strategies

Wagon drilling operations involve potential challenges and risks that must be managed effectively:

a) Ground Conditions

- Unstable or fractured rock formations can lead to ground collapse or rock falls.

- Mitigation: Conduct thorough ground assessments, implement appropriate ground support measures, and monitor site conditions.

b) Equipment Failure

- Mechanical breakdowns or malfunctions can cause delays or safety hazards.

- Mitigation: Regular maintenance, preventive inspections, and having backup equipment ready.

c) Environmental Factors

- Dust, noise, and vibrations can impact workers’ health and the surrounding environment.

- Mitigation: Use dust suppression systems, minimize noise levels, and implement vibration control measures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wagon Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wagon Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wagon Drill Operator is responsible for the safe and efficient operation of a wagon drill, a large surface drill used to bore holes for blasting in mining and construction projects.

1. Set up and operate the wagon drill

This involves preparing the drill site, assembling the drill, and setting up the drill bit.

2. Monitor the drilling process

The operator must closely monitor the drill bit’s progress and make adjustments as needed to ensure that the hole is being drilled to the correct specifications.

3. Perform maintenance on the wagon drill

The operator is responsible for performing regular maintenance on the wagon drill, including lubricating the moving parts, checking the drill bit, and ensuring that the drill is running smoothly.

4. Safely store and transport the wagon drill

The operator must follow safety protocols when storing and transporting the wagon drill to prevent accidents and damage to the equipment.

Interview Tips

To prepare for an interview for a Wagon Drill Operator position, it is important to have a strong understanding of the key responsibilities of the job.

1. Research the company and the position

Learn about the company’s size, industry, and culture. This will help you understand the company’s needs and the role of the Wagon Drill Operator.

2. Practice answering common interview questions

Prepare for questions about your experience, skills, and qualifications. Practice answering these questions clearly and concisely.

3. Be prepared to demonstrate your knowledge of the wagon drill

If possible, bring a portfolio of your work or be prepared to talk about your experience operating a wagon drill in detail.

4. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally and arrive on time for your interview.

5. Be enthusiastic and ask questions

Show the interviewer that you are excited about the opportunity and that you have a genuine interest in the company and the position.

Next Step:

Now that you’re armed with the knowledge of Wagon Drill Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wagon Drill Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini