Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wagon Driller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

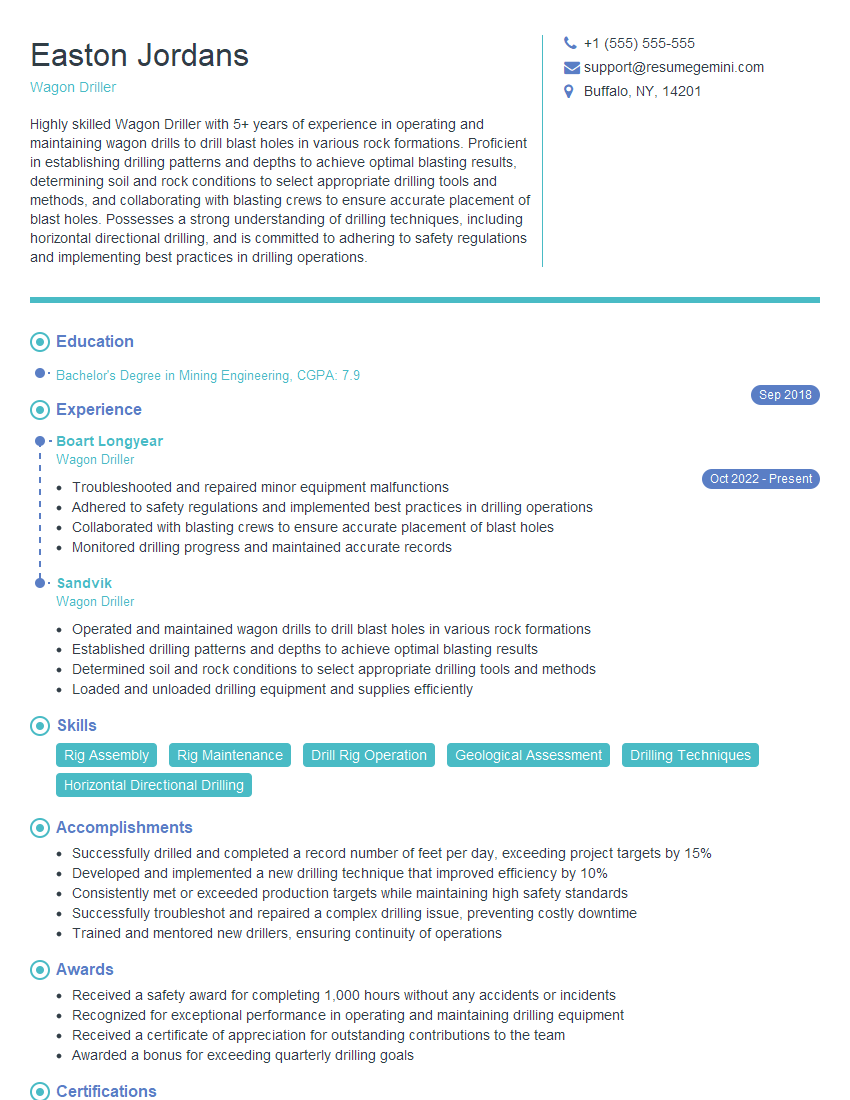

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wagon Driller

1. Describe the drilling process of a wagon drill.

The drilling process of a wagon drill involves the following steps:

- The drill is positioned over the desired drilling location.

- The drill head is lowered into the ground using the hydraulic system of the wagon drill.

- The drill bit rotates and hammers against the rock, breaking it down into smaller pieces.

- The cuttings are removed from the hole using compressed air or water.

- The drill head is raised and the wagon drill is moved to the next drilling location.

2. Explain the different types of drill bits used in wagon drilling and their applications.

Button Bits

- Used for drilling in hard and abrasive rock formations.

- Feature carbide buttons that are brazed onto the tip of the bit.

- Provide high penetration rates and long life.

Cross Bits

- Used for drilling in soft to medium-hard rock formations.

- Feature X-shaped cutting edges that provide good penetration rates.

Drag Bits

- Used for drilling in soft and unconsolidated formations.

- Feature a flat cutting face with serrated edges that scrape the rock.

3. Discuss the importance of maintaining proper drilling parameters for optimal performance.

- Penetration Rate: The rate at which the drill bit advances into the rock.

- Thrust: The force applied to the drill bit.

- Rotation Speed: The speed at which the drill bit rotates.

- Air or Water Pressure: The pressure of the compressed air or water used to remove cuttings from the hole.

- Drill Bit Selection: Choosing the appropriate drill bit for the rock formation being drilled.

4. Describe the safety precautions that must be followed while operating a wagon drill.

- Wear appropriate personal protective equipment (PPE).

- Ensure that the drill is properly secured and stabilized.

- Never stand directly in front of the drill while it is operating.

- Use proper lifting techniques when handling heavy objects.

- Be aware of the surroundings and potential hazards.

5. Explain how you would troubleshoot and resolve common problems encountered while using a wagon drill.

- Drill bit is not advancing: Check if the drill bit is sharp and free of wear, ensure proper thrust and rotation speed, check for any blockages in the hole.

- Excessive vibration: Check for loose components, ensure the drill bit is securely attached, inspect for any damage to the wagon drill.

- Loss of air pressure: Check for leaks in the air line, ensure the air compressor is operating correctly.

- Drill is overheating: Check for adequate lubrication, ensure the cooling system is functioning properly.

6. Discuss the maintenance procedures required to keep a wagon drill in good working condition.

- Daily Maintenance: Visual inspection, cleaning, lubrication.

- Weekly Maintenance: Check and adjust hydraulic fluid levels, inspect air lines and filters.

- Monthly Maintenance: Inspect and tighten bolts and connections, check drill bit sharpness and wear.

- Regular Maintenance: Overhaul of major components, such as the engine and hydraulic system.

7. Explain the role of the operator in ensuring the safe and efficient operation of a wagon drill.

- Adhere to safety guidelines and wear appropriate PPE.

- Inspect the wagon drill before and after each shift.

- Monitor drilling parameters and adjust as necessary.

- Identify and troubleshoot any problems promptly.

- Operate the wagon drill smoothly and avoid sudden movements.

8. Describe the environmental regulations that must be considered when using a wagon drill.

- Noise pollution: Use of noise-reducing equipment, working during designated hours.

- Air pollution: Use of dust collectors, proper ventilation.

- Water pollution: Prevention of oil and fuel leaks, proper disposal of drilling fluids.

- Land contamination: Proper disposal of drill cuttings, minimizing soil disturbance.

9. Explain how you would manage a team of wagon drill operators.

- Provide clear instructions and training.

- Monitor performance and provide feedback.

- Ensure safety regulations are followed.

- Resolve any issues or conflicts among team members.

- Maintain a positive and productive work environment.

10. Discuss the career progression opportunities available for a wagon drill operator.

- Senior Wagon Drill Operator

- Drill Supervisor

- Drilling Foreman

- Drilling Manager

- Safety Officer

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wagon Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wagon Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wagon Drillers are responsible for operating and maintaining wagon drills. They are also responsible for the safety of themselves and others on the job site.

1. Operate Wagon Drills

Wagon drillers operate wagon drills to create holes in the ground for blasting or excavation. They must be able to safely and efficiently operate the drill and its controls.

- Set up and position the wagon drill

- Operate the drill to create holes in the ground

- Monitor the drill’s operation and make adjustments as needed

2. Maintain Wagon Drills

Wagon drillers are responsible for maintaining their drills. They must be able to identify and troubleshoot problems, and make repairs as needed.

- Inspect the drill regularly for wear and tear

- Lubricate and adjust the drill as needed

- Repair or replace damaged parts

3. Safety

Wagon drillers must follow all safety regulations and procedures. They must be able to identify and avoid hazards, and they must be able to use their equipment safely.

- Wear appropriate safety gear

- Follow all safety procedures

- Identify and avoid hazards

4. Other Responsibilities

Wagon drillers may also be responsible for other tasks, such as:

- Assisting with blasting operations

- Setting up and removing barricades

- Cleaning up the work site

Interview Tips

In order to ace the interview for a Wagon Driller position, it is important to be prepared. Here are a few tips:

1. Research the Company and the Position

Before the interview, take some time to research the company and the position. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read about the company in industry publications

- Talk to people who work for the company

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you can expect to be asked. Practice answering these questions in advance so that you can deliver confident and articulate responses.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with operating and maintaining wagon drills?

3. Highlight Your Safety Experience

Safety is a top priority for wagon drillers. Be sure to highlight your experience with safety procedures and regulations in your interview.

- Describe your experience with following safety procedures

- Explain how you have identified and avoided hazards in the past

- Discuss your knowledge of safety regulations

4. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience operating and maintaining wagon drills. Be prepared to discuss your experience in detail.

- Describe the different types of wagon drills you have operated

- Explain how you have maintained wagon drills

- Discuss any challenges you have faced while operating or maintaining wagon drills

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wagon Driller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!