Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Warp Doffer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

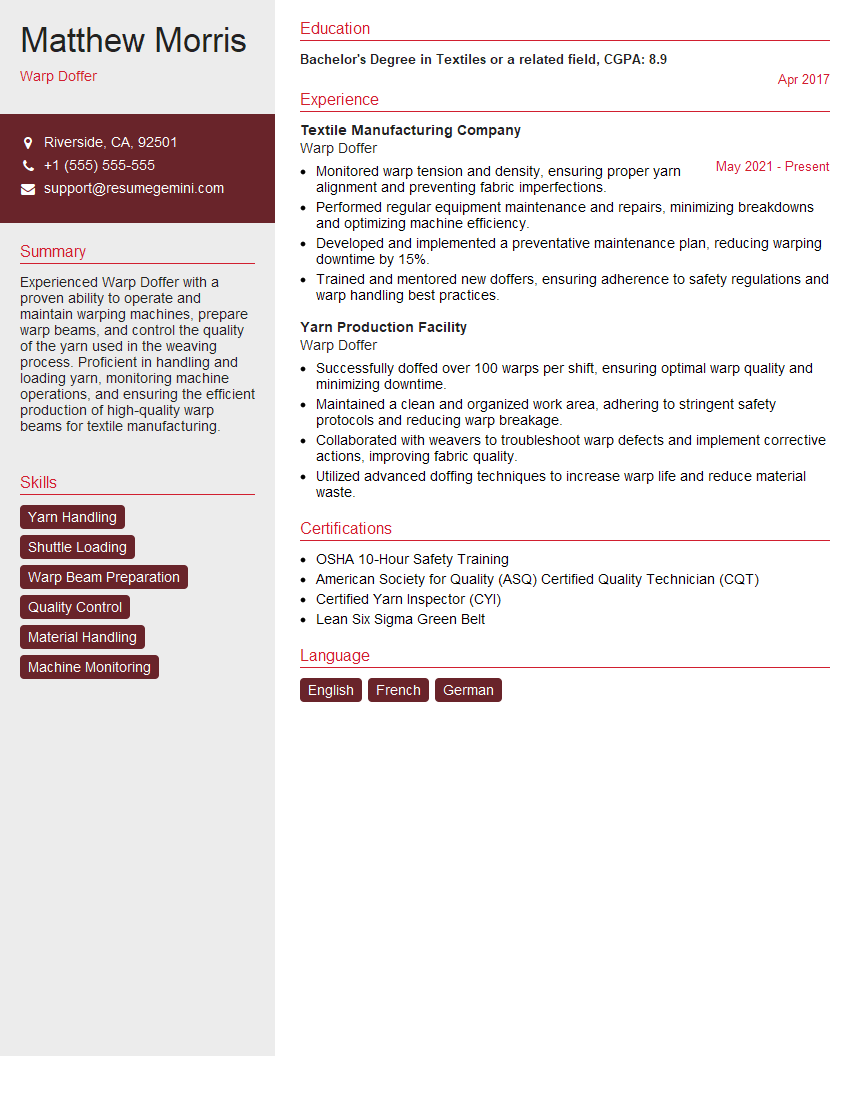

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Warp Doffer

1. Explain the process of doffing a warp beam.

- Stop the warper and tie off the yarn ends.

- Loosen the beam clamps and remove the beam from the warper.

- Place the beam on a doffing stand or cart.

- Cut the yarn ends and remove the old warp beam.

- Place the new warp beam on the warper.

- Tighten the beam clamps and thread the yarn ends through the warper.

- Start the warper and check for proper tension.

2. What are the different types of warp beams?

types of warp beams

- Sectional warp beams

- Beam warps

- Flanged beams

- Tricot beams

Uses of these warp beams

- Sectional warp beams are used for weaving narrow fabrics.

- Beam warps are used for weaving wide fabrics.

- Flanged beams are used for weaving fabrics with a high number of ends.

- Tricot beams are used for weaving tricot fabrics.

3. What are the factors that affect the quality of a warp beam?

- The quality of the yarn

- The tension of the yarn

- The speed of the warper

- The temperature and humidity of the environment.

4. How do you troubleshoot a warp beam that is causing problems on the loom?

- Check the tension of the yarn.

- Check the speed of the warper.

- Check the temperature and humidity of the environment.

- Inspect the beam for any damage.

- If the problem persists, contact the warp beam manufacturer.

5. What are the safety precautions that must be taken when working with warp beams?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a hard hat.

- Be aware of the location of all pinch points and rotating parts.

- Do not attempt to move a warp beam that is too heavy for you.

- Use a forklift or other lifting device to move heavy warp beams.

- Store warp beams in a safe and secure location.

6. Describe any special techniques required for warping delicate yarns.

- Use a slower warping speed.

- Use a lower tension setting.

- Use a larger creel package.

- Use a yarn conditioner to prevent the yarn from breaking.

7. Explain how you would calculate the correct beam flange size for a given warp.

- Measure the width of the warp.

- Add 2 inches to the width of the warp.

- Divide the sum by 2.

- The result is the correct beam flange size.

8. How do you maintain a warp beam to ensure it runs smoothly on the loom?

- Inspect the beam for any damage.

- Clean the beam with a vacuum cleaner or brush.

- Lubricate the beam bearings.

- Check the tension of the yarn.

- Store the beam in a cool, dry place.

9. What are some of the common problems that can occur with warp beams?

- Yarn breakage

- Beam wobble

- Beam flange damage

- Bearing failure

10. What are your troubleshooting tips for resolving warp beam problems?

- Check the tension of the yarn.

- Check the speed of the warper.

- Check the temperature and humidity of the environment.

- Inspect the beam for any damage.

- Lubricate the beam bearings.

- If the problem persists, contact the warp beam manufacturer.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Warp Doffer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Warp Doffer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Warp Doffers are responsible for ensuring the smooth operation of textile manufacturing machines by removing empty warp beams and replacing them with full ones. Their key responsibilities include:

1. Beam Handling

Loading and unloading warp beams manually or using a crane

- Inspecting beams for any damages or defects

- Properly positioning and securing the beams on the machine

2. Machine Operation

Operating and monitoring the warp beaming machine

- Adjusting machine settings to maintain proper tension and yarn quality

- Identifying and troubleshooting machine malfunctions

- Maintaining a clean and organized work area

3. Yarn Handling

Preparing and handling yarn for warping

- Inspecting yarn for defects and ensuring its quality

- Setting up and maintaining yarn creels

- Monitoring yarn tension and making necessary adjustments

4. Safety and Quality Control

Ensuring workplace safety and maintaining quality standards

- Following safety protocols and procedures

- Inspecting warped beams for quality and meeting specifications

- Reporting any issues or concerns to supervisors

Interview Tips

To ace the interview for a Warp Doffer position, follow these tips:

1. Research the Company and Position

Research the textile manufacturing industry, the specific company you’re applying to, and the role of a Warp Doffer.

- Gather information about the company’s products, services, and manufacturing processes.

- Identify the key responsibilities and qualifications for the Warp Doffer position.

2. Highlight Your Relevant Experience and Skills

Emphasize your hands-on experience in textile manufacturing, particularly in warping and beam handling.

- Provide specific examples of your ability to operate and monitor warp beaming machines.

- Quantify your accomplishments whenever possible, such as the number of beams you’ve handled or the production improvements you’ve achieved.

3. Showcase Your Safety and Quality Awareness

Stress your commitment to workplace safety and quality control.

- Explain how you ensure the proper handling and storage of beams and yarn.

- Describe your understanding of quality standards and your role in maintaining them.

4. Demonstrate Teamwork and Communication Skills

In most manufacturing environments, teamwork and communication are crucial.

- Share examples of your ability to work effectively as part of a team.

- Highlight your communication skills and how you effectively convey information to supervisors, colleagues, and customers.

5. Be Prepared for Technical Questions

Interviewers may ask technical questions to assess your understanding of the warping process and machinery.

- Be prepared to discuss different types of warp beaming machines and their components.

- Practice troubleshooting common machine malfunctions and explaining how you would resolve them.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Warp Doffer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!