Are you gearing up for an interview for a Warp Yarn Sorter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Warp Yarn Sorter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

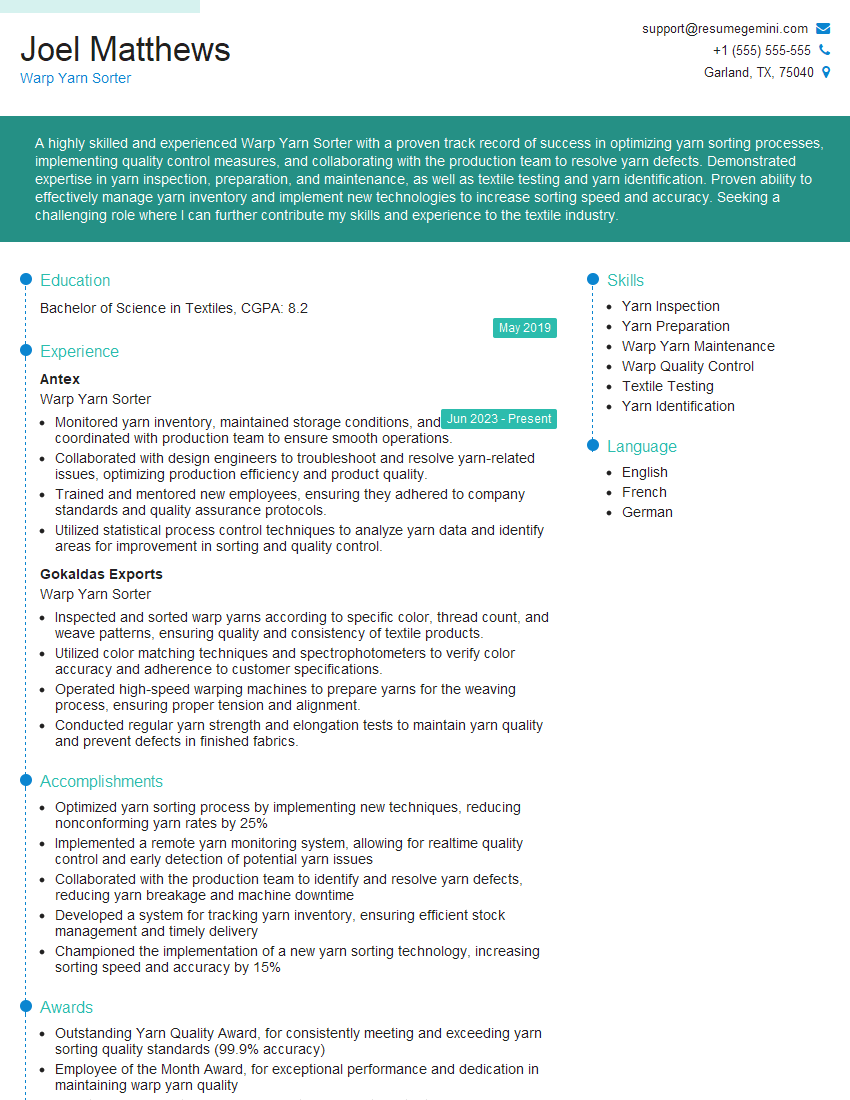

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Warp Yarn Sorter

1. How do you check the quality of the yarn and identify any defects?

To check the quality of the yarn and identify any defects, I follow a systematic process:

- Visual Inspection: Visually examine the yarn for any visible defects, such as knots, slubs, unevenness, or color variations.

- Tactile Inspection: Run my fingers along the yarn to detect any changes in texture, thickness, or smoothness that could indicate a defect.

- Tensile Strength Test: Use a tensiometer to measure the breaking strength of the yarn and ensure it meets the required specifications.

- Elongation Test: Measure the percentage of elongation of the yarn under a controlled load to check its elasticity and tensile properties.

- Twist Test: Determine the number of twists per unit length of the yarn to ensure it meets the specifications and provides the desired fabric structure.

2. How do you handle different types of yarn, including natural and synthetic fibers?

Understanding Fiber Properties:

- Cotton: Known for its softness, absorbency, and breathability. Requires gentle handling and steaming for wrinkle removal.

- Polyester: Strong, durable, and wrinkle-resistant. Can withstand heat and moisture.

- Nylon: Elastic, wrinkle-resistant, and moisture-absorbent. Needs special care to prevent snagging and pilling.

Handling Techniques:

- Natural Fibers: Handle with care to avoid damage. Use low heat and gentle steaming for wrinkle removal.

- Synthetic Fibers: Can withstand higher temperatures and moisture. Use moderate heat and press with care to avoid melting.

3. How do you maintain and calibrate the sorting equipment used in the process?

To maintain and calibrate the sorting equipment:

- Regular Cleaning: Clean all sensors, rollers, and conveyors regularly to remove dust, debris, and yarn residue.

- Inspection: Thoroughly inspect the equipment for any loose wires, worn parts, or damage that could affect its performance.

- Calibration: Calibrate the sensors using standard yarn samples to ensure accurate sorting and minimize errors.

- Software Updates: Ensure the sorting software is up-to-date to address any bugs or performance issues.

- Preventive Maintenance: Follow recommended maintenance schedules to prevent breakdowns and extend the equipment’s lifespan.

4. What are the quality control measures you implement to ensure the accuracy and efficiency of the sorting process?

To ensure the accuracy and efficiency of the sorting process, I implement the following quality control measures:

- Random Sampling: Regularly take random samples of sorted yarn to verify the accuracy of the sorting equipment.

- Process Audits: Conduct periodic audits to monitor the sorting process and identify areas for improvement.

- Performance Metrics: Track key performance indicators such as sorting efficiency, accuracy, and defect detection rate.

- Supplier Audits: Evaluate yarn suppliers to ensure they meet quality standards and provide consistent yarn properties.

- Continuous Improvement: Regularly review and implement strategies to optimize the sorting process and improve its overall performance.

5. How do you handle customer complaints and resolve any issues related to the sorting process?

- Active Listening: Actively listen to the customer’s concerns and gather all necessary information.

- Verification: Verify the complaint by reviewing the sorting data, yarn samples, and equipment logs.

- Root Cause Analysis: Conduct a thorough investigation to identify the root cause of the issue.

- Corrective Action: Develop and implement corrective actions to address the issue and prevent its recurrence.

- Customer Communication: Keep the customer informed throughout the process and provide regular updates on the progress.

6. What is your understanding of the principles behind warp yarn sorting, and how do you apply them in your work?

The principles behind warp yarn sorting involve using sensors to detect specific characteristics of the yarn, such as color, thickness, and texture.

- Color Sorting: Uses color sensors to identify and separate yarns based on their color shades.

- Thickness Sorting: Employs thickness sensors to detect variations in the diameter of the yarn.

- Texture Sorting: Utilizes sensors to differentiate between different textures, such as smooth, slubby, or hairy yarns.

I apply these principles by carefully calibrating the sensors to match the desired sorting criteria and ensuring that the equipment is operating optimally to achieve accurate and efficient results.

7. How do you prioritize and manage multiple tasks in a fast-paced work environment?

- Task Assessment: Evaluate the urgency and importance of each task.

- Prioritization: Determine the order in which tasks should be completed based on their priority.

- Time Management: Allocate time effectively to ensure critical tasks are completed on time.

- Delegation: Assign tasks to others when necessary to optimize workload management.

- Communication: Regularly update supervisors and colleagues on task progress to ensure alignment.

8. How do you stay up-to-date on the latest technologies and best practices in warp yarn sorting?

- Industry Events: Attend conferences and workshops to learn about new technologies and advancements.

- Online Research: Regularly read trade publications, technical articles, and manufacturer websites.

- Training and Development: Participate in training programs and workshops to enhance my skills and knowledge.

- Networking: Connect with industry professionals to exchange knowledge and ideas.

- Feedback and Evaluation: Seek feedback on my performance and identify areas for improvement.

9. How do you maintain a clean and organized work area to ensure efficiency and safety?

- Regular Cleaning: Regularly clean and disinfect work surfaces, equipment, and tools.

- Organized Storage: Store yarn, supplies, and tools in designated areas to maintain order and accessibility.

- Waste Disposal: Promptly dispose of yarn waste and debris to prevent clutter and potential hazards.

- Equipment Maintenance: Ensure equipment is clean and well-maintained to prevent malfunctions and accidents.

- Safety Compliance: Adhere to all safety regulations and guidelines to create a safe working environment.

10. How do you handle working as part of a team and collaborate with others to achieve common goals?

- Communication: Effectively communicate with team members to ensure clear understanding of tasks and goals.

- Collaboration: Actively participate in team meetings and discussions to share ideas and contribute to decision-making.

- Support: Provide support and assistance to team members when needed to achieve collective objectives.

- Respect: Treat all team members with respect and value their opinions and contributions.

- Problem-Solving: Work together with team members to identify and resolve issues that arise during the sorting process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Warp Yarn Sorter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Warp Yarn Sorter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Warp Yarn Sorter is responsible for sorting and inspecting warp yarns to ensure they meet the required quality standards. Their primary tasks include:

1. Yarn Sorting and Inspection

Sorting warp yarns based on count, twist, colour, and other specifications to maintain consistency in production.

- Visually inspecting yarns for defects such as knots, breaks, uneven thickness, and contamination.

- Identifying and removing defective yarns to prevent imperfections in the final product.

2. Yarn Preparation

Preparing warp yarns for further processing by winding them onto beams, spools, or creels.

- Monitoring yarn tension and speed to ensure proper winding.

- Maintaining proper yarn storage conditions to prevent damage.

3. Production Quality Control

Ensuring the quality of warp yarns meets established standards by conducting regular inspections.

- Using measuring and testing equipment to assess yarn properties such as strength, elongation, and twist.

- Reporting any discrepancies or quality issues to supervisors for corrective actions.

4. Equipment Maintenance

Maintaining and ensuring the proper functioning of yarn sorting and winding equipment.

- Cleaning and lubricating machines to prevent breakdowns.

- Adjusting and calibrating equipment to maintain accuracy and precision.

Interview Tips

To prepare effectively for an interview for a Warp Yarn Sorter position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company’s history, industry, and products. Understand the specific requirements of the Warp Yarn Sorter role, especially regarding sorting and inspection techniques.

- Visit the company’s website, read industry reports, and connect with current or former employees on LinkedIn.

2. Highlight Relevant Skills and Experience

Emphasize your skills in yarn sorting, inspection, and quality control. Showcase your ability to identify and resolve yarn defects, maintain equipment, and ensure production quality.

- Quantify your accomplishments, providing specific examples of how you contributed to improving yarn quality or reducing production errors.

3. Practice Answering Common Interview Questions

Prepare answers to typical interview questions related to the Warp Yarn Sorter role. Consider questions about your experience with yarn sorting techniques, quality control procedures, and equipment maintenance.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide detailed examples.

4. Prepare Industry-Specific Questions

Show your interest in the industry by preparing questions about the company’s yarn sourcing, quality standards, or recent advancements in yarn sorting technology.

- Asking insightful questions demonstrates your enthusiasm and eagerness to learn.

5. Dress Professionally and Arrive on Time

Make a positive first impression by dressing appropriately and arriving punctually for your interview. Proper attire indicates respect for the company and the interviewer.

- First impressions matter, so ensure you present yourself professionally and courteously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Warp Yarn Sorter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.