Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wash Driller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

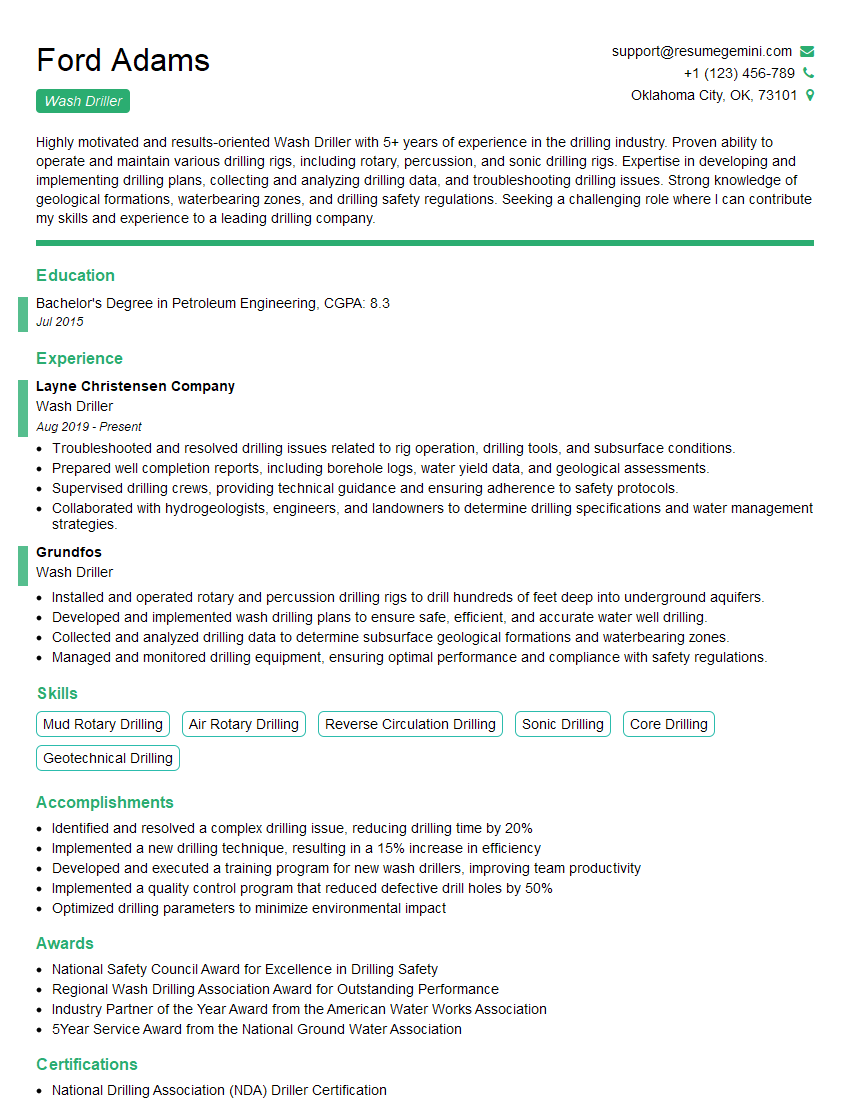

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wash Driller

1. Describe the process of conducting a wash borehole drilling operation?

Here is an overview of the wash borehole drilling process:

- Site preparation: The first step is to prepare the site for drilling. This involves clearing the area of vegetation and obstacles, and leveling the ground.

- Drilling the borehole: The next step is to drill the borehole. This is done using a wash boring rig, which uses a rotating drill bit to cut into the ground. Water is pumped down the drill hole to help remove the cuttings.

- Installing the casing: Once the borehole has been drilled, a casing is installed. The casing is a pipe that lines the borehole and prevents it from collapsing.

- Developing the well: The final step is to develop the well. This involves pumping water out of the well until the water is clear and free of sediment.

2. What are the different types of wash boring rigs and their applications?

- Truck-mounted rigs: These rigs are mounted on a truck chassis and are used for drilling in a variety of locations, including construction sites, mining sites, and environmental remediation sites.

- Trailer-mounted rigs: These rigs are mounted on a trailer and are used for drilling in remote locations where access is limited.

- Skid-mounted rigs: These rigs are mounted on skids and are used for drilling in tight spaces, such as inside buildings or on rooftops.

3. What are the different types of drill bits used in wash boring and their applications?

- Tricone bits: These bits are the most common type of bit used in wash boring. They have three rotating cones that cut into the ground and are used for drilling in a variety of soil and rock conditions.

- Roller bits: These bits have a number of rollers that rotate on the bit body. They are used for drilling in hard rock conditions.

- Drag bits: These bits are used for drilling in soft soil conditions.

4. What are the different types of drilling fluids used in wash boring and their applications?

- Water: Water is the most common drilling fluid used in wash boring. It is used for drilling in a variety of soil and rock conditions.

- Mud: Mud is a mixture of water and clay or other additives. It is used for drilling in unstable soil conditions.

- Foam: Foam is a mixture of water and air. It is used for drilling in very unstable soil conditions.

5. What are the different types of casing used in wash boring and their applications?

- Steel casing: Steel casing is the most common type of casing used in wash boring. It is strong and durable and can be used in a variety of soil and rock conditions.

- PVC casing: PVC casing is a lightweight and inexpensive type of casing. It is used for drilling in soft soil conditions.

- ABS casing: ABS casing is a strong and durable type of casing that is resistant to corrosion. It is used for drilling in hard rock conditions.

6. What are the different types of well development techniques and their applications?

- Pumping: Pumping is the most common method of well development. It involves pumping water out of the well until the water is clear and free of sediment.

- Airlifting: Airlifting is a method of well development that uses compressed air to lift water out of the well. It is used for developing wells in deep or difficult-to-reach locations.

- Swabbing: Swabbing is a method of well development that uses a swab to remove sediment from the well. It is used for developing wells in shallow or narrow wells.

7. What are the different types of well maintenance techniques and their applications?

- Chlorination: Chlorination is a method of well maintenance that uses chlorine to kill bacteria and other microorganisms in the well water. It is used to prevent the spread of waterborne diseases.

- Filtration: Filtration is a method of well maintenance that uses a filter to remove sediment and other contaminants from the well water. It is used to improve the quality of the well water.

- Acidizing: Acidizing is a method of well maintenance that uses acid to dissolve scale and other deposits that can build up in the well. It is used to improve the flow of water from the well.

8. What are the different types of well abandonment techniques and their applications?

- Grouting: Grouting is a method of well abandonment that uses grout to seal the well and prevent groundwater from contaminating the surrounding environment. It is used to abandon wells that are no longer in use.

- Pulling: Pulling is a method of well abandonment that involves pulling the casing and screen out of the well. It is used to abandon wells that are no longer in use and that are not contaminated.

- Filling: Filling is a method of well abandonment that involves filling the well with sand, gravel, or other materials. It is used to abandon wells that are no longer in use and that are contaminated.

9. What are the different types of safety hazards associated with wash boring and how can they be mitigated?

- Falling objects: Falling objects can be a hazard when working on a drill rig. To mitigate this hazard, wear a hard hat and stay clear of areas where objects could fall.

- Pinch points: Pinch points can be a hazard when working with machinery. To mitigate this hazard, be aware of pinch points and keep your hands clear of them.

- Electrical hazards: Electrical hazards can be a hazard when working on a drill rig. To mitigate this hazard, wear insulated gloves and be aware of the location of electrical wires.

- Chemical hazards: Chemical hazards can be a hazard when working with drilling fluids. To mitigate this hazard, wear chemical-resistant gloves and clothing and follow the manufacturer’s instructions for handling drilling fluids.

10. What are the different types of environmental regulations that apply to wash boring and how can they be complied with?

- The Clean Water Act: The Clean Water Act regulates the discharge of pollutants into water bodies. To comply with the Clean Water Act, wash boring operations must use drilling fluids that are non-toxic and biodegradable and must dispose of drilling fluids properly.

- The Clean Air Act: The Clean Air Act regulates the emission of air pollutants. To comply with the Clean Air Act, wash boring operations must use drilling equipment that is in good working order and must minimize the emission of air pollutants.

- The Resource Conservation and Recovery Act: The Resource Conservation and Recovery Act regulates the disposal of hazardous waste. To comply with the Resource Conservation and Recovery Act, wash boring operations must dispose of hazardous waste properly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wash Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wash Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wash Drillers are highly specialized professionals responsible for operating wash drilling equipment to extract soil samples for geotechnical and environmental investigations. Their key responsibilities include:

1. Drilling Operations

Executing drilling operations using wash drilling techniques to obtain soil samples.

- Preparing drilling equipment and selecting appropriate drill bits and drilling fluids.

- Maintaining proper drilling parameters to ensure accurate sample collection.

2. Sample Handling and Documentation

Handling, preserving, and packaging soil samples for laboratory analysis.

- Logging soil samples, recording drilling data, and maintaining field records.

- Preparing chain-of-custody documentation for sample traceability.

3. Equipment Maintenance and Calibration

Performing preventive maintenance and calibrating drilling equipment to ensure optimal performance.

- Inspecting and servicing drilling rigs, pumps, and other equipment.

- Calibrating drilling sensors and gauges to ensure accuracy of data collection.

4. Field Safety and Compliance

Adhering to safety protocols and regulatory guidelines in the field.

- Wearing appropriate PPE, following safe work practices, and maintaining a clean worksite.

- Complying with environmental regulations and obtaining necessary permits.

Interview Tips

To ace a Wash Driller interview, candidates should focus on showcasing their technical proficiency, attention to detail, and field experience. Here are some interview preparation tips and hacks:

1. Research the Company and Position

Before the interview, thoroughly research the company’s background, projects, and specific requirements for the Wash Driller position. This demonstrates your interest and preparedness.

- Visit the company website and review project portfolios.

- Read job descriptions and industry publications to gain insights into the role.

2. Highlight Technical Expertise

Emphasize your technical knowledge and experience in wash drilling techniques, drilling equipment, and soil sampling methods. Quantify your accomplishments and provide specific examples.

- Describe your proficiency in using various drill rigs, drill bits, and drilling fluids.

- Explain your understanding of soil types and their impact on drilling parameters.

3. Demonstrate Attention to Detail

Wash Drillers must possess exceptional attention to detail when handling sensitive soil samples. Highlight your ability to meticulously follow protocols, record data accurately, and maintain a well-organized work area.

- Describe your experience in logging soil samples and maintaining detailed field records.

- Explain your understanding of sample preservation and chain-of-custody documentation.

4. Share Field Experience

Emphasize your practical field experience in wash drilling operations. Discuss the types of projects you have worked on and the challenges you have encountered.

- Describe your experience in different drilling environments and soil conditions.

- Share examples of how you have overcome challenges in the field, such as equipment malfunctions or difficult drilling conditions.

5. Showcase Safety Consciousness

Safety is paramount in wash drilling. Highlight your understanding of safety protocols and compliance requirements. Explain your experience in maintaining a clean and organized worksite.

- Describe your knowledge of PPE requirements and safe work practices.

- Explain your awareness of environmental regulations and the importance of obtaining necessary permits.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wash Driller interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.