Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Watch Parts Grinder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Watch Parts Grinder so you can tailor your answers to impress potential employers.

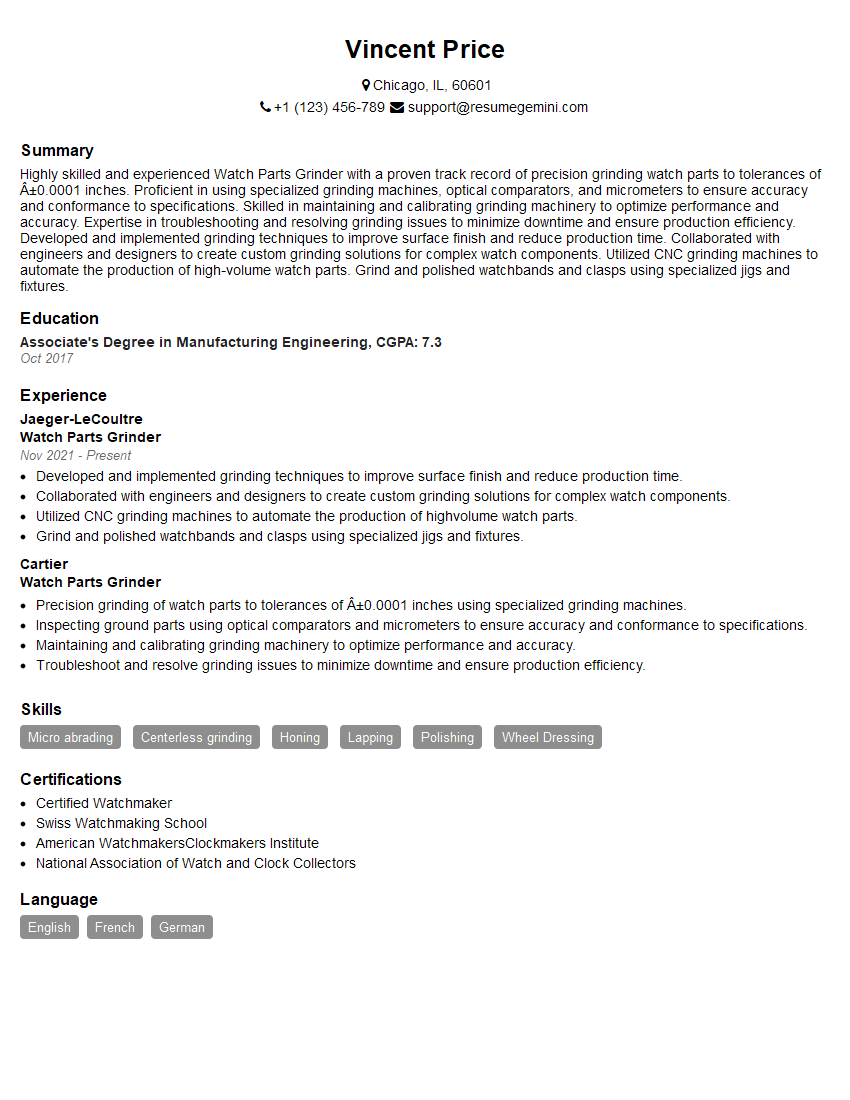

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Watch Parts Grinder

1. What are the different types of watch parts that you have experience grinding?

As a Watch Parts Grinder, I have experience grinding a wide variety of watch parts, including:

- Gears

- Pinions

- Balances

- Springs

- Jewels

2. What are the different types of grinding machines that you have operated?

CNC Grinding Machines

- Computer Numerical Control (CNC) grinding machines are used to grind complex shapes and profiles with high precision.

- CNC grinding machines are typically used to grind parts for high-end watches and other precision instruments.

Manual Grinding Machines

- Manual grinding machines are used to grind simpler shapes and profiles.

- Manual grinding machines are typically used to grind parts for less expensive watches and other products.

3. What are the different types of grinding wheels that you have used?

I have used a variety of grinding wheels, including:

- Diamond wheels

- CBN wheels

- Electroplated wheels

- Abrasive wheels

The type of grinding wheel used depends on the material being ground and the desired finish.

4. What are the different types of grinding fluids that you have used?

I have used a variety of grinding fluids, including:

- Water-based fluids

- Oil-based fluids

- Synthetic fluids

The type of grinding fluid used depends on the material being ground, the grinding machine being used, and the desired finish.

5. What are the different types of finishes that you can achieve with grinding?

I can achieve a variety of finishes with grinding, including:

- Rough finishes

- Semi-rough finishes

- Semi-fine finishes

- Fine finishes

- Superfine finishes

The type of finish achieved depends on the grinding wheel used, the grinding machine being used, and the grinding parameters.

6. What are the different types of tolerances that you can achieve with grinding?

I can achieve a variety of tolerances with grinding, including:

- Dimensional tolerances

- Geometric tolerances

- Surface finish tolerances

The type of tolerance achieved depends on the grinding machine being used, the grinding parameters, and the skill of the operator.

7. What are the different types of inspection methods that you use to ensure the quality of your work?

I use a variety of inspection methods to ensure the quality of my work, including:

- Visual inspection

- Dimensional inspection

- Geometric inspection

- Surface finish inspection

The type of inspection method used depends on the type of part being inspected and the required tolerance.

8. What are the different types of maintenance tasks that you perform on your grinding machines?

I perform a variety of maintenance tasks on my grinding machines, including:

- Cleaning and lubrication

- Wheel dressing

- Spindle inspection and adjustment

- Electrical troubleshooting

Regular maintenance is essential to ensure the accuracy and precision of grinding machines.

9. What are the different types of safety precautions that you take when operating grinding machines?

I take a variety of safety precautions when operating grinding machines, including:

- Wearing proper safety gear

- Guarding all moving parts

- Using proper grinding techniques

- Following all safety procedures

Safety is always the top priority when operating grinding machines.

10. What are the different types of training that you have received in watch parts grinding?

I have received a variety of training in watch parts grinding, including:

- On-the-job training

- Classroom training

- Vendor training

- Online training

Ongoing training is essential to stay up-to-date on the latest grinding technologies and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Watch Parts Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Watch Parts Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Watch Parts Grinder is responsible for various intricate tasks involving the grinding of watch components, ensuring precision and accuracy in the manufacturing process. Their key job responsibilities include:

1. Grinding and Finishing Watch Parts

Grind and finish watch components, such as gears, pins, and springs, to precise specifications using a variety of grinding machines.

- Operate grinding machines, such as centerless grinders, surface grinders, and cylindrical grinders.

- Select and use the appropriate abrasives, grinding wheels, and coolants.

2. Quality Control and Inspection

Inspect and measure ground parts using precision measuring instruments, such as calipers, micrometers, and optical comparators, to ensure they meet specified tolerances.

- Identify and correct any defects or imperfections in the grinding process.

- Maintain accurate records of grinding operations and inspection results.

3. Machine Maintenance and Calibration

Perform routine maintenance and calibration of grinding machines to ensure optimal performance and accuracy.

- Clean and lubricate machines, replace worn parts, and adjust settings.

- Calibrate machines using standard gauges and reference materials.

4. Production and Efficiency

Optimize production processes to meet production targets and maintain high levels of efficiency.

- Monitor production output and identify areas for improvement.

- Implement process improvements to reduce cycle times and increase productivity.

Interview Tips

To effectively prepare for an interview for a Watch Parts Grinder position, it is essential to have a thorough understanding of the key job responsibilities and demonstrate your skills and experience in these areas.

1. Research the Company and Industry

Research the watch manufacturing industry, the company’s history and products, and the specific role and responsibilities of a Watch Parts Grinder.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

2. Highlight Your Grinding Skills and Experience

Emphasize your expertise in operating grinding machines, selecting abrasives, and achieving precise tolerances.

- Provide specific examples of your work, such as grinding complex watch components within tight tolerances.

- Quantify your results whenever possible, such as “Achieved a 99% success rate in grinding gears to within 0.001 mm tolerance.”

3. Showcase Your Quality Control and Inspection Abilities

Demonstrate your proficiency in using precision measuring instruments and adhering to quality standards.

- Explain your process for inspecting ground parts and identifying defects.

- Describe your experience in maintaining inspection records and implementing corrective actions.

4. Emphasize Your Attention to Detail and Accuracy

Highlight your meticulous nature and commitment to producing high-quality results.

- Provide examples of projects where you maintained a high level of accuracy and consistency.

- Explain how you handle situations where precision is crucial.

5. Prepare Questions for the Interviewer

Prepare thoughtful questions that demonstrate your interest in the role and the company.

- Ask about the company’s production processes, quality control standards, and training opportunities.

- Inquire about the challenges and opportunities for growth within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Watch Parts Grinder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!