Feeling lost in a sea of interview questions? Landed that dream interview for Water Jet Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Water Jet Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

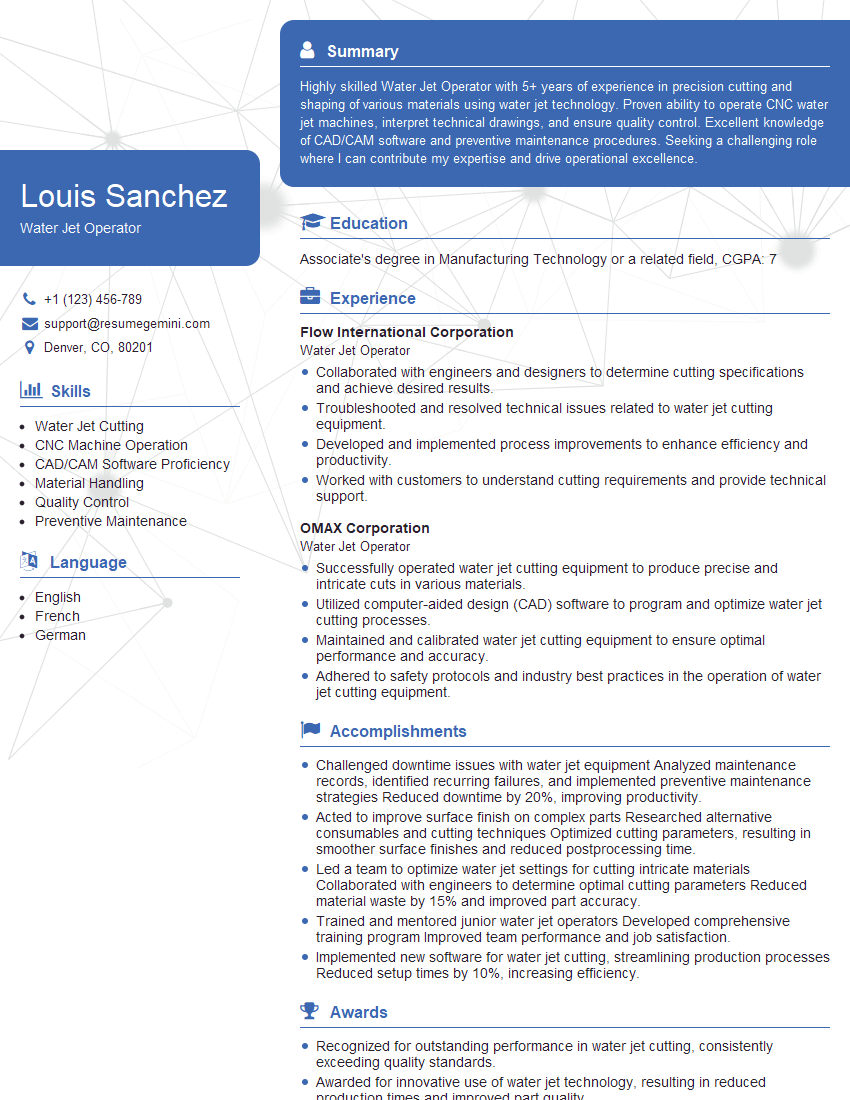

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Water Jet Operator

1. Explain the basic principles of water jet cutting.

Water jet cutting is a process that uses a high-pressure stream of water to cut through various materials. Here are the basic principles of water jet cutting:

- A high-pressure pump generates a stream of water at pressures ranging from 40,000 to 60,000 psi.

- The water is then forced through a small nozzle, which focuses the stream into a narrow, high-velocity jet.

- The water jet is directed at the material to be cut, eroding it and creating a narrow kerf.

- Abrasive particles are often added to the water jet to enhance its cutting ability, especially for harder materials.

2. Describe the different types of water jet cutting machines.

There are two main types of water jet cutting machines:

Abrasive Waterjet Cutting Machines

- Use a mixture of water and abrasive particles to cut materials.

- Can cut a wide range of materials, including metals, ceramics, composites, and glass.

Pure Waterjet Cutting Machines

- Use only water to cut materials.

- Suitable for cutting softer materials, such as foam, rubber, and textiles.

3. What are the advantages and disadvantages of water jet cutting?

Advantages:

- Can cut a wide range of materials, including hard and brittle materials.

- Produces a precise and clean cut with minimal heat-affected zone.

- Environmentally friendly as it uses only water or water with abrasives.

Disadvantages:

- Can be slower than other cutting methods.

- Requires a large amount of water, which can be expensive in some areas.

4. What are the key factors to consider when selecting a water jet nozzle?

The following factors should be considered when selecting a water jet nozzle:

- The type of material being cut.

- The desired cut quality.

- The thickness of the material being cut.

- The water pressure and flow rate available.

5. How do you maintain a water jet cutting system?

Regular Maintenance:

- Check and clean the water filter regularly.

- Inspect the nozzle for wear and tear.

- Lubricate moving parts according to the manufacturer’s instructions.

Periodic Maintenance:

- Calibrate the machine to ensure accuracy.

- Replace worn parts, such as the nozzle and seals.

- Perform a thorough inspection of the entire system.

6. What safety precautions should be taken when operating a water jet cutting machine?

- Wear appropriate protective gear, including eye protection, gloves, and earplugs.

- Never point the water jet at yourself or others.

- Secure the workpiece properly to prevent it from moving during the cutting process.

- Follow the manufacturer’s safety instructions carefully.

7. Describe the process of programming a water jet cutting machine.

Programming a water jet cutting machine involves the following steps:

- Create a CAD drawing of the desired cut.

- Convert the CAD drawing into a CNC program.

- Transfer the CNC program to the water jet cutting machine.

- Set the cutting parameters, such as water pressure, flow rate, and cutting speed.

8. How do you troubleshoot common problems with water jet cutting machines?

- Poor cut quality: Check the nozzle for wear or damage. Adjust the cutting parameters, such as water pressure or cutting speed.

- Leaking water: Inspect the seals and hoses for damage. Tighten any loose connections.

- Machine not starting: Check the power supply and electrical connections. Ensure that the water supply is adequate.

9. What is your experience with water jet cutting?

In my previous role as a Water Jet Operator at [Company Name], I was responsible for operating and maintaining a water jet cutting machine. I have experience in cutting a wide range of materials, including metals, ceramics, and composites. I am also proficient in programming the machine and troubleshooting common problems.

10. Why are you interested in this Water Jet Operator position?

I am interested in this Water Jet Operator position because I am passionate about water jet cutting technology and its applications. I believe that my skills and experience would be a valuable asset to your team. I am eager to learn more about your company and contribute to your success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Water Jet Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Water Jet Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Water Jet Operator plays a significant role in ensuring the smooth functioning of industrial processes involving water jet cutting technology. Their key responsibilities include:

1. Machine Setup and Operation

Setting up and operating water jet cutting machines according to established procedures.

- Loading and securing materials in the cutting area.

- Inputting cutting parameters and initiating cutting processes.

2. Material Handling

Handling and positioning various materials for cutting operations.

- Inspecting materials for defects or damage.

- Loading, unloading, and repositioning materials during cutting.

3. Machine Monitoring and Maintenance

Monitoring machine operations and performing regular maintenance tasks.

- Observing cutting processes for any irregularities or problems.

- Checking and replacing filters, nozzles, and other machine components.

4. Safety Compliance

Adhering to safety protocols and maintaining a safe working environment.

- Wearing appropriate safety gear, including protective clothing and eyewear.

- Following established operating procedures and safety regulations.

Interview Preparation Tips

To ace the interview for a Water Jet Operator position, candidates should consider the following preparation tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the water jet cutting industry by researching their history, products or services, and market position.

- Familiarize yourself with the company’s mission, values, and recent developments.

- Learn about the industry’s trends, challenges, and advancements.

2. Practice Your Skills and Knowledge

Review the job description and identify the specific skills and knowledge required for the role. Practice demonstrating these skills through relevant examples:

- Highlight your experience in operating water jet cutting machines, including the different types of machines and materials you have worked with.

- Showcase your understanding of machine setup, maintenance, and troubleshooting procedures.

3. Prepare for Common Interview Questions

Research typical interview questions and prepare thoughtful answers that align with the job requirements:

- Explain your experience in water jet cutting operations and the different industries you have worked in.

- Describe a challenging situation you faced while operating water jet cutting machines and how you overcame it.

- Share your knowledge of safety protocols and your commitment to maintaining a safe work environment.

4. Emphasize Your Attention to Detail

Water jet cutting requires precision and attention to detail. Highlight your ability to follow instructions accurately, minimize errors, and maintain a high level of quality:

- Provide examples of where your attention to detail has contributed to successful cutting outcomes.

- Explain your process for ensuring the accuracy and precision of your work.

Next Step:

Now that you’re armed with the knowledge of Water Jet Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Water Jet Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini