Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Water Main Pipe Layer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Water Main Pipe Layer so you can tailor your answers to impress potential employers.

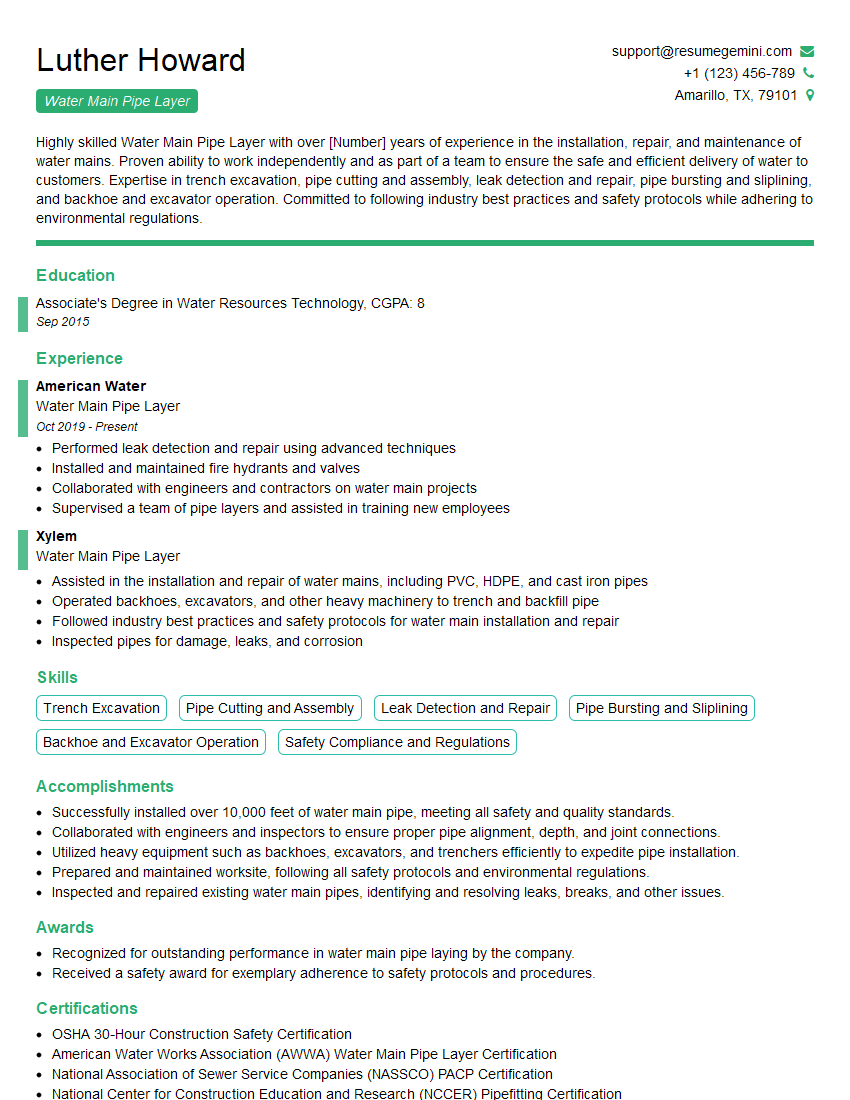

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Water Main Pipe Layer

1. Describe the steps involved in installing a water main pipe?

Sure, here are the steps involved in installing a water main pipe:

- Plan the installation and obtain the necessary permits.

- Excavate the trench for the pipe.

- Install the bedding material and the pipe.

- Backfill the trench and compact the soil.

- Pressure test the pipe to ensure it is watertight.

- Disinfect the pipe to remove any bacteria.

- Connect the pipe to the water supply and the distribution system.

2. What are the different types of water main pipes, and what are their advantages and disadvantages?

The three most common types of water main pipes are:

Ductile iron pipes

- Advantages: strong, durable, and resistant to corrosion.

- Disadvantages: heavy and expensive.

PVC pipes

- Advantages: lightweight, flexible, and easy to install.

- Disadvantages: not as strong as ductile iron pipes and can be damaged by sunlight.

Polyethylene pipes

- Advantages: lightweight, flexible, and resistant to corrosion.

- Disadvantages: can be damaged by sunlight and rodents.

3. What are the safety precautions that must be taken when working with water main pipes?

When working with water main pipes, it is important to take the following safety precautions:

- Wear appropriate safety gear, including hard hat, safety glasses, gloves, and steel-toed boots.

- Be aware of the location of underground utilities before digging.

- Use proper lifting techniques when handling heavy pipes.

- Be aware of the risk of trench collapse and take precautions to prevent it.

- Follow all safety procedures and guidelines established by your employer.

4. How do you troubleshoot a water main leak?

- First, identify the location of the leak.

- Once the leak is located, the water supply should be shut off.

- The leak can then be repaired by replacing the damaged section of pipe or by using a repair clamp.

- Once the leak is repaired, the water supply can be turned back on and the system can be pressure tested to ensure that the leak has been fixed.

5. What are the different methods of trenching for water main pipes?

- Manual trenching: This method involves digging the trench by hand using shovels and picks.

- Mechanical trenching: This method involves using a trenching machine to dig the trench.

- Trenchless methods: These methods involve installing the pipe without digging a trench. Some trenchless methods include horizontal directional drilling (HDD) and pipe bursting.

6. How do you determine the size of a water main pipe?

The size of a water main pipe is determined by a number of factors, including the flow rate, the pressure, and the length of the pipe.

- Flow rate: The flow rate is the amount of water that flows through the pipe per unit of time.

- Pressure: The pressure is the force exerted by the water on the walls of the pipe.

- Length: The length of the pipe is the distance from the source of the water to the point of use.

7. How do you prepare a water main pipe for installation?

Before installing a water main pipe, it is important to prepare the pipe by cleaning it and removing any burrs or sharp edges.

- Cleaning: The pipe can be cleaned using a wire brush or a power washer.

- Removing burrs and sharp edges: Burrs and sharp edges can be removed using a file or a grinder.

8. How do you connect two water main pipes together?

There are a number of different ways to connect two water main pipes together, including using mechanical joints, flanged joints, and welded joints.

- Mechanical joints: Mechanical joints are made using a rubber gasket and a metal clamp.

- Flanged joints: Flanged joints are made using two flanges that are bolted together.

- Welded joints: Welded joints are made by welding the two pipes together.

9. How do you test a water main pipe for leaks?

There are a number of different ways to test a water main pipe for leaks, including using a pressure test, a vacuum test, and an acoustic test.

- Pressure test: A pressure test involves filling the pipe with water and then pressurizing it to a certain level.

- Vacuum test: A vacuum test involves creating a vacuum in the pipe and then monitoring the pressure to see if it drops.

- Acoustic test: An acoustic test involves listening for leaks using a stethoscope or a leak detector.

10. What are the different types of water main pipe fittings?

There are a number of different types of water main pipe fittings, including elbows, tees, crosses, and reducers.

- Elbows: Elbows are used to change the direction of the pipe.

- Tees: Tees are used to connect three pipes together.

- Crosses: Crosses are used to connect four pipes together.

- Reducers: Reducers are used to connect pipes of different sizes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Water Main Pipe Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Water Main Pipe Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Water Main Pipe Layers are integral to the maintenance of our water infrastructure, ensuring a steady supply of clean water to homes and businesses.

1. Pipeline Installation

Their responsibilities include installing, repairing, and replacing water mains and service lines, ensuring a continuous and reliable water supply.

2. Excavation and Trenching

They excavate trenches to lay pipes, using precision tools to ensure proper depth and alignment.

3. Pipe Laying and Installation

They skillfully place and join pipes, using specialized equipment such as welding or mechanical joints to secure connections.

4. Leak Detection and Repair

They are adept at identifying leaks in water mains and service lines, and promptly repair them to prevent water wastage and damage.

5. Safety and Compliance

They strictly adhere to safety regulations and industry standards, ensuring that their work adheres to environmental and safety guidelines.

Interview Tips

Preparing for an interview can significantly increase your chances of success. Here are some key tips to help you ace your interview for a Water Main Pipe Layer position:

1. Research the Company and Industry

Familiarize yourself with the company’s profile, its areas of expertise, and the specific responsibilities of the role. Learn about the latest industry trends and best practices to showcase your knowledge.

2. Highlight Your Skills and Experience

Emphasize your technical skills, such as trenching, pipe installation, leak detection, and repair techniques. Quantify your accomplishments and provide specific examples to demonstrate your expertise.

3. Show Your Commitment to Safety

Stress your commitment to safety and compliance. Highlight your understanding of industry standards and your experience in working safely in hazardous environments.

4. Practice Your Answers

Anticipate common interview questions and prepare thoughtful and concise answers. Practice delivering your responses confidently and clearly.

5. Be Enthusiastic and Professional

Approach the interview with enthusiasm and professionalism. Demonstrate your interest in the role, the company, and the industry. Be courteous and respectful to the interviewers, and maintain a positive attitude throughout.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Water Main Pipe Layer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Water Main Pipe Layer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.