Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Water Sander interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Water Sander so you can tailor your answers to impress potential employers.

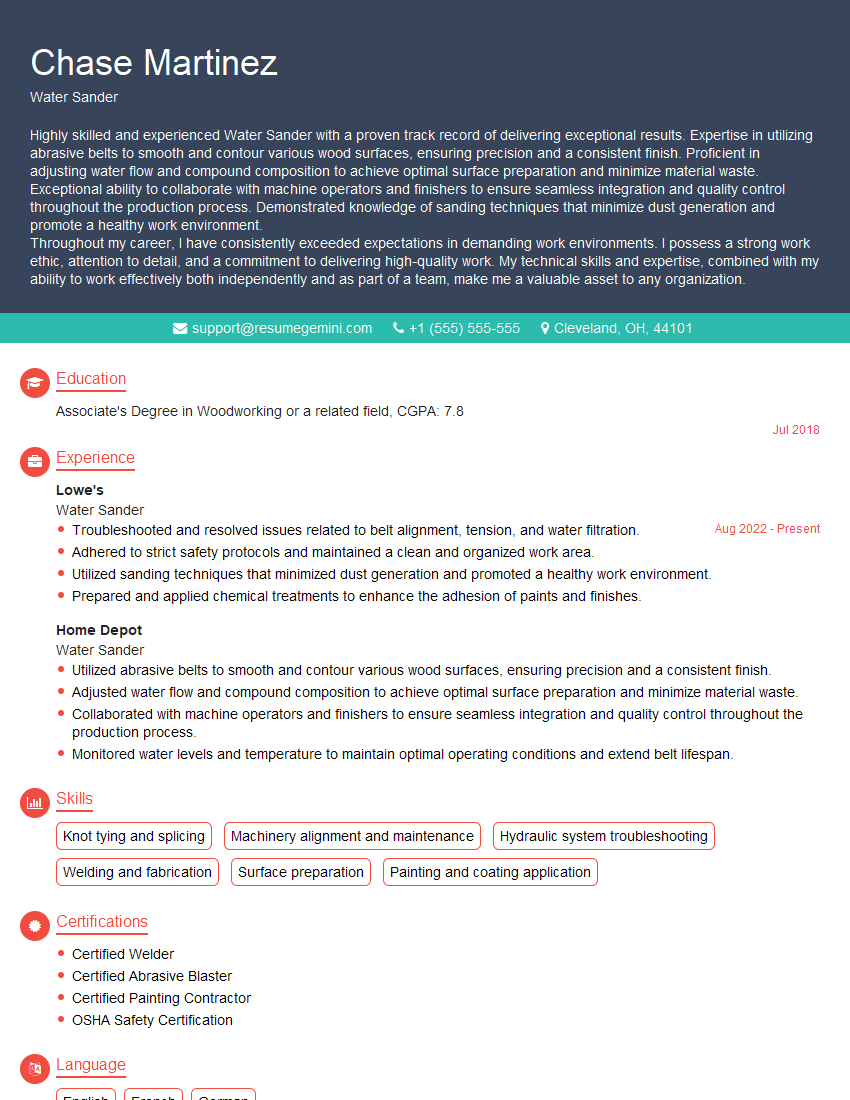

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Water Sander

1. What are the key considerations when selecting the appropriate water sander for a specific application?

- The type of material being sanded

- The desired finish

- The size and shape of the workpiece

- The budget

2. How do you determine the correct grit size for a water sander?

Factors to consider:

- The type of material being sanded

- The desired finish

- The speed of the sander

General guidelines:

- Coarse grit (60-80) for removing large amounts of material or shaping

- Medium grit (120-180) for smoothing surfaces and removing imperfections

- Fine grit (220-320) for polishing and achieving a high-quality finish

3. What are the advantages and disadvantages of using a water sander versus a dry sander?

Advantages of water sanders:- Produces less dust

- Prevents clogging of the sandpaper

- Cools the workpiece and reduces the risk of burning

- Can be messy

- May require more setup time

- Can damage some materials if not used properly

4. How do you maintain a water sander to ensure optimal performance and longevity?

- Clean the sander regularly

- Inspect the pads and sandpaper for wear

- Check the water level and add water as needed

- Store the sander in a clean and dry place

5. What are some common troubleshooting tips for water sanders?

- If the sander is not sanding effectively, check the grit size of the sandpaper

- If the sander is clogging, clean the pads and sandpaper

- If the sander is leaking water, check the seals and gaskets

- If the sander is making noise, check the bearings and brushes

6. What are the different types of water sanders available?

- Random orbital sanders

- Belt sanders

- Disc sanders

7. What are the safety precautions that should be taken when using a water sander?

- Wear appropriate safety gear

- Use the sander in a well-ventilated area

- Do not use the sander on wet surfaces

- Be aware of the electrical cord

8. What are the different types of abrasives used in water sanding?

- Aluminum oxide

- Zirconia

- Ceramic

9. What is the difference between wet sanding and dry sanding?

- Wet sanding uses water to lubricate the sanding process

- Dry sanding does not use water

- Wet sanding produces less dust and provides a smoother finish

10. What are the advantages of using a water sander for woodworking?

- Produces a smoother finish

- Reduces dust

- Prevents clogging of the sandpaper

- Cools the workpiece and reduces the risk of burning

11. What are some of the challenges associated with using a water sander?

- Can be messy

- May require more setup time

- Can damage some materials if not used properly

12. How do you choose the right water sander for your needs?

- Consider the type of material you will be sanding

- Determine the desired finish

- Choose a sander with the appropriate power and speed

- Select a sander with the right features for your needs

13. What are some tips for getting the best results from a water sander?

- Use the correct grit size for the material you are sanding

- Apply even pressure to the sander

- Move the sander in a circular motion

- Keep the sander wet

14. What are some common mistakes to avoid when using a water sander?

- Using the wrong grit size

- Applying too much pressure to the sander

- Moving the sander too quickly

- Letting the sander dry out

15. How do you maintain a water sander?

- Clean the sander after each use

- Inspect the sander regularly for wear and tear

- Replace the sandpaper as needed

- Store the sander in a dry place

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Water Sander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Water Sander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Water Sanders are responsible for a variety of tasks in the manufacturing process. They operate water sanding machines to smooth and finish surfaces of products, ensuring they meet quality standards. The following are key job responsibilities of a Water Sander:

1. Sanding

Using water sanding machines, Water Sanders remove burrs, imperfections, and excess material from surfaces of products. They adjust machine settings and select appropriate sanding belts to achieve desired smoothness and finish.

- Operate water sanding machines to sand and smooth surfaces of products

- Adjust machine settings and select sanding belts based on product specifications

- Ensure sanded surfaces meet required quality standards

2. Quality Control

Water Sanders inspect sanded surfaces for defects, ensuring they meet specifications. They use measuring tools and gauges to verify dimensions and smoothness.

- Inspect sanded surfaces for defects and imperfections

- Use measuring tools and gauges to verify dimensions and smoothness

- Identify and report any non-conforming products

3. Equipment Maintenance

Water Sanders are responsible for maintaining and cleaning water sanding machines. They perform regular inspections, lubricate moving parts, and replace worn components to ensure optimal performance.

- Inspect and maintain water sanding machines

- Lubricate moving parts and replace worn components

- Ensure machines are operating safely and efficiently

4. Safety Compliance

Water Sanders follow safety protocols to minimize risks in the workplace. They wear appropriate personal protective equipment and adhere to established safety guidelines.

- Follow established safety protocols and guidelines

- Wear appropriate personal protective equipment

- Report any safety concerns or hazards

Interview Tips

Preparing for a Water Sander interview can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take time to research the company and the specific Water Sander position. Learn about the company’s products, services, and industry standing. Understand the job responsibilities and qualifications required for the role.

- Visit the company website and social media pages

- Read industry news and articles

- Identify the specific skills and experience required for the position

2. Practice Common Interview Questions

Common interview questions for Water Sanders may include:

- Tell us about your experience in water sanding.

- How do you ensure the quality of your work?

- What safety precautions do you take when operating water sanding machines?

- How do you handle working in a fast-paced environment?

- What are your strengths and weaknesses as a Water Sander?

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest in the position and company. Prepare a few questions related to the job responsibilities, company culture, or industry trends.

- What are the expectations for this role in the first 90 days?

- Can you describe the company’s commitment to safety?

- What are the opportunities for professional development and growth within the company?

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This demonstrates respect for the interviewer and the company.

- Wear clean, pressed clothing

- Arrive at the interview location on time

- Bring a portfolio or examples of your work if relevant

5. Be Confident and Enthusiastic

Confidence and enthusiasm can make a positive impact on the interviewer. Believe in your abilities and show your passion for the Water Sander role. Be clear and concise in your answers, and highlight your skills and experience.

- Maintain eye contact and speak clearly

- Be positive and enthusiastic about the position

- Emphasize your relevant skills and experience

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Water Sander, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Water Sander positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.