Are you gearing up for an interview for a Water Supply Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Water Supply Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

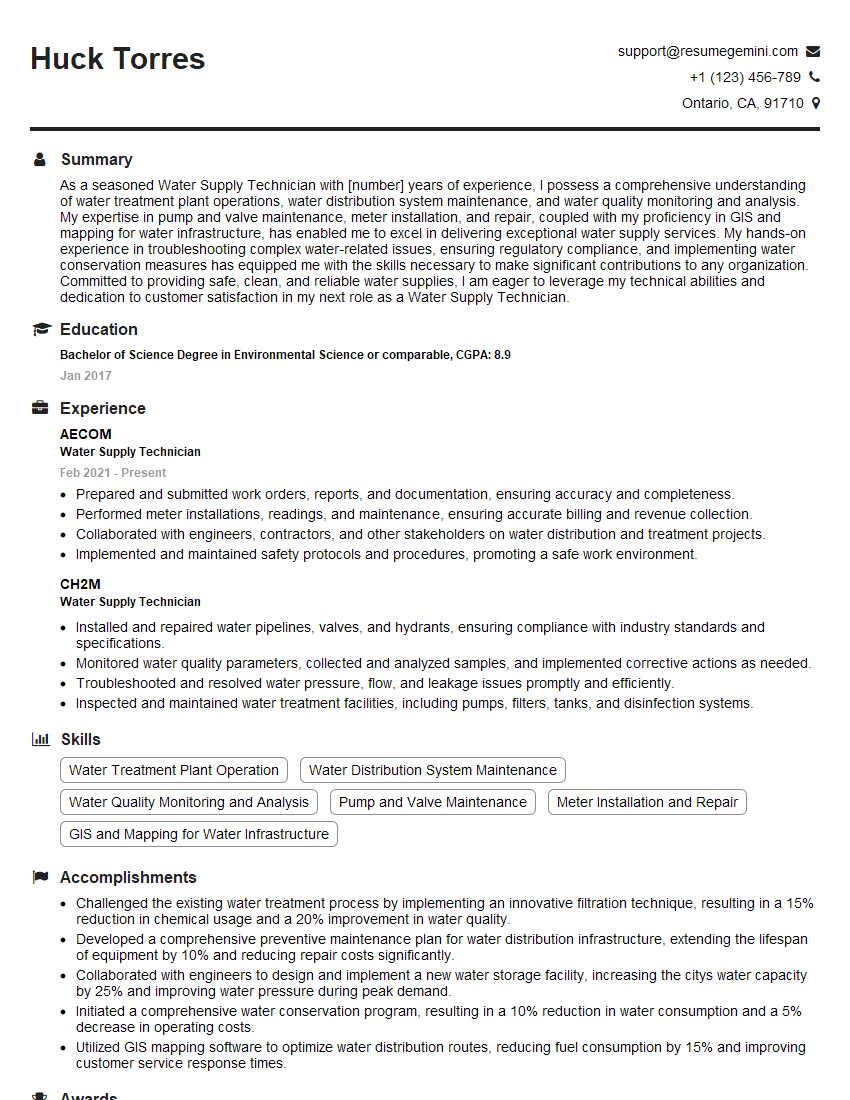

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Water Supply Technician

1. Briefly describe the water distribution system and its components?

A water distribution system is a complex network of pipes, valves, tanks, and pumps that delivers water from a source to consumers. The components of a water distribution system include:

- Water sources: These can be surface water sources (such as rivers or lakes) or groundwater sources (such as aquifers).

- Water treatment plants: These facilities treat raw water to make it safe for drinking.

- Storage tanks: These store treated water to meet peak demand and provide backup in case of emergencies.

- Distribution pipes: These carry treated water from storage tanks to consumers.

- Valves: These control the flow of water through the system.

- Pumps: These increase the pressure of water to ensure that it reaches consumers at an adequate rate.

2. What are the different types of water meters used in water distribution systems?

- Positive displacement meters: These meters measure the volume of water that passes through them by physically displacing a volume of water within the meter. They are generally more accurate than other types of meters but are also more expensive.

- Velocity meters: These meters measure the velocity of water flowing through them and use this information to calculate the volume of water that has passed through them. They are less accurate than positive displacement meters but are also less expensive.

- Ultrasonic meters: These meters use ultrasonic waves to measure the velocity of water flowing through them. They are more accurate than velocity meters but are also more expensive.

3. What are the common materials used for water distribution pipes?

- PVC (polyvinyl chloride): PVC is a lightweight and corrosion-resistant plastic that is commonly used for water distribution pipes. It is relatively inexpensive and easy to install.

- Ductile iron: Ductile iron is a strong and durable material that is often used for large-diameter water distribution pipes. It is more expensive than PVC but is also more resistant to corrosion and cracking.

- Copper: Copper is a corrosion-resistant and antimicrobial material that is often used for small-diameter water distribution pipes. It is more expensive than PVC and ductile iron but is also more durable.

4. What are the key considerations when designing a water distribution system?

- Population: The population of the area to be served by the system is a key factor in determining the size and capacity of the system.

- Water demand: The water demand of the area to be served by the system is also a key factor in determining the size and capacity of the system.

- Water sources: The availability of water sources is a key factor in determining the location and design of the system.

- Terrain: The terrain of the area to be served by the system can also affect the design of the system.

- Cost: The cost of constructing and operating the system is also a key factor in the design process.

5. What are the most common problems that can occur in water distribution systems?

- Leaks: Leaks are one of the most common problems that can occur in water distribution systems. They can be caused by a variety of factors, such as corrosion, damage to pipes, or improper installation.

- Blockages: Blockages are another common problem that can occur in water distribution systems. They can be caused by a variety of factors, such as sediment, debris, or ice.

- Water quality problems: Water quality problems can also occur in water distribution systems. They can be caused by a variety of factors, such as contamination of the water source, problems with the water treatment process, or corrosion of pipes.

6. What are the different methods that can be used to maintain water distribution systems?

- Inspection: Regular inspection of water distribution systems is essential to identify and correct potential problems. Inspections can be performed visually, using cameras, or using other methods.

- Cleaning: Water distribution systems should be cleaned regularly to remove sediment, debris, and other contaminants. Cleaning can be performed using a variety of methods, such as flushing, jetting, or chemical cleaning.

- Repair: When problems are identified in a water distribution system, they should be repaired as soon as possible. Repairs can be performed using a variety of methods, such as patching, replacement, or relining.

7. What are the different types of water conservation measures that can be implemented in water distribution systems?

- Water-efficient fixtures: Installing water-efficient fixtures, such as low-flow toilets and showerheads, can reduce water consumption.

- Leak detection and repair: Identifying and repairing leaks can help to reduce water loss.

- Water audits: Conducting water audits can help to identify areas where water is being wasted and develop strategies to reduce water consumption.

8. What are the different types of water quality monitoring that can be performed in water distribution systems?

- Physical monitoring: Physical monitoring includes tests for parameters such as turbidity, color, and odor.

- Chemical monitoring: Chemical monitoring includes tests for parameters such as pH, chlorine, and lead.

- Biological monitoring: Biological monitoring includes tests for parameters such as coliform bacteria and E. coli.

9. What are the different types of water treatment processes that can be used in water distribution systems?

- Disinfection: Disinfection is the process of killing or inactivating microorganisms in water. Common disinfection methods include chlorination, ozonation, and ultraviolet disinfection.

- Filtration: Filtration is the process of removing particles from water. Common filtration methods include rapid sand filtration, slow sand filtration, and membrane filtration.

- Coagulation and flocculation: Coagulation and flocculation are processes that help to remove particles from water by forming larger particles that can be more easily removed by filtration.

10. What are the different types of water distribution system modeling that can be used to optimize system performance?

- Hydraulic modeling: Hydraulic modeling is used to simulate the flow of water through a water distribution system. This can be used to identify areas of the system that are experiencing problems, such as low pressure or high flow velocities.

- Water quality modeling: Water quality modeling is used to simulate the transport of contaminants through a water distribution system. This can be used to identify areas of the system that are at risk of contamination.

- Optimization modeling: Optimization modeling is used to identify the best way to operate a water distribution system to meet specific goals, such as minimizing water loss or maximizing water quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Water Supply Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Water Supply Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Water Supply Technicians play a vital role in ensuring a safe and reliable water supply for communities. Their responsibilities encompass a wide range of technical and operational tasks.

1. Water Distribution System Maintenance and Repair

Water Supply Technicians are responsible for maintaining and repairing the water distribution system, including pipes, valves, hydrants, and meters. They respond to leaks, breaks, and other emergencies to ensure uninterrupted water service.

2. Water Quality Monitoring and Testing

Water Supply Technicians collect and analyze water samples to ensure that the water meets drinking water standards. They perform tests for various contaminants, such as bacteria, chemicals, and heavy metals.

3. New Water System Installation and Upgrade

Water Supply Technicians may assist in the installation and upgrade of new water systems or components, such as pumps, filters, and reservoirs. They ensure that the systems are installed and operate according to specifications.

4. Customer Support and Communication

Water Supply Technicians interact with customers, answering questions about water service and billing. They respond to complaints and provide technical support to resolve issues.

Interview Tips

To ace an interview for a Water Supply Technician role, candidates should prepare thoroughly and present themselves professionally. Here are some key tips:

1. Research the Company and Position

Research the water utility company and the specific position you are applying for. Understand their mission, values, and the scope of responsibilities expected of a Water Supply Technician.

2. Highlight Relevant Experience and Skills

Emphasize your experience in water distribution system maintenance, repair, and water quality monitoring. Highlight your technical skills, problem-solving abilities, and customer service orientation.

3. Demonstrate Technical Knowledge

Be prepared to discuss technical concepts related to water distribution systems, water quality testing, and system upgrades. Show that you have a solid understanding of water treatment and distribution processes.

4. Showcase Customer Service Skills

Water Supply Technicians interact with customers and provide technical support. Demonstrate your customer service skills by providing examples of how you resolved complaints or provided assistance to customers.

5. Emphasize Safety and Regulations

Water Supply Technicians work in a safety-sensitive environment. Emphasize your commitment to safety and your knowledge of industry regulations related to water quality and system maintenance.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Water Supply Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Water Supply Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.