Are you gearing up for an interview for a Waterman position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Waterman and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

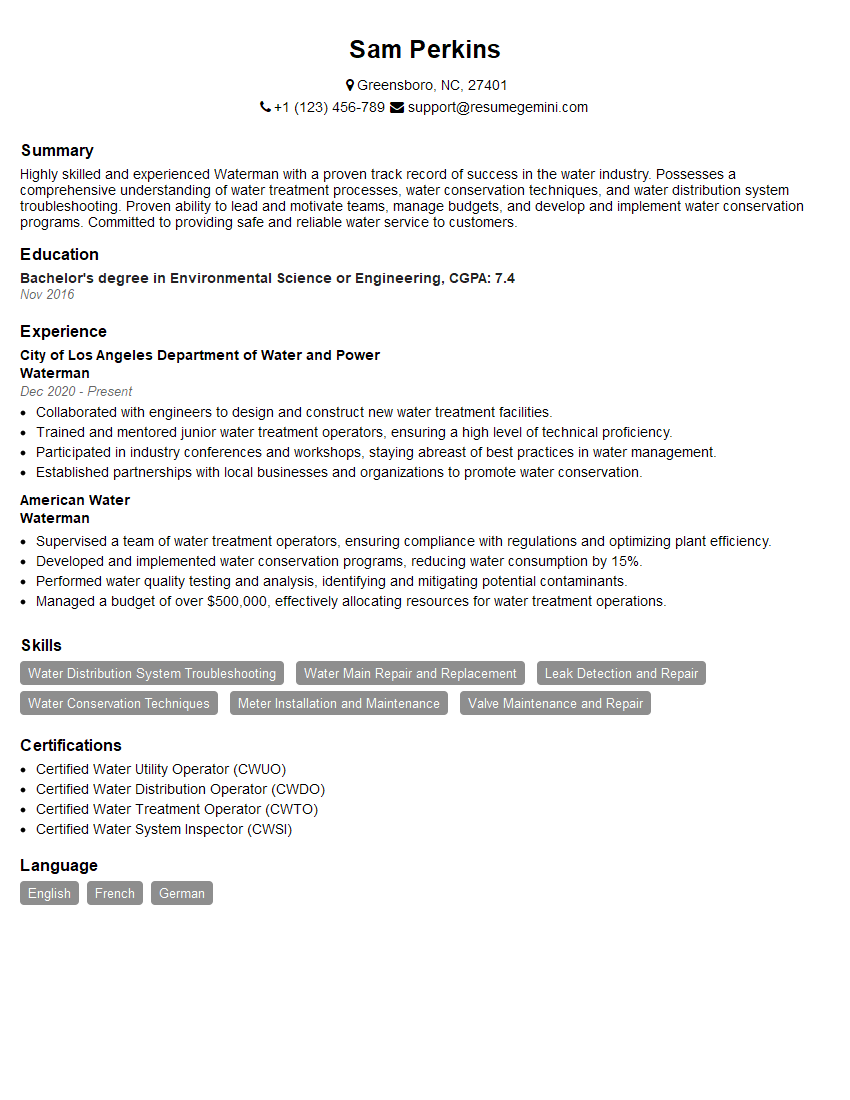

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Waterman

1. We use injectors for controlling and changing the flow of fluid in Waterman. Explain the different types of injectors?

There are three main types of injectors used in Waterman:

- Needle injectors: These injectors use a thin, sharp needle to inject fluid into the material. They are commonly used for precise injections and can be used to inject fluids into hard materials.

- Venturi injectors: These injectors use the Venturi effect to create a vacuum that draws fluid into the injector. They are commonly used for high-volume injections and can be used to inject fluids into soft materials.

- Syringe injectors: These injectors use a plunger to push fluid into the material. They are commonly used for small-volume injections and can be used to inject fluids into both hard and soft materials.

2. What are the different types of fluids that can be used in Waterman?

- Water-based fluids: These fluids are made from water and can be used for a variety of applications, including cutting, grinding, and polishing.

- Oil-based fluids: These fluids are made from oil and can be used for a variety of applications, including cutting, grinding, and honing.

- Synthetic fluids: These fluids are made from synthetic materials and can be used for a variety of applications, including cutting, grinding, and polishing.

3. What are the different types of materials that can be machined using Waterman?

- Metals: Waterman can be used to machine a variety of metals, including steel, aluminum, and titanium.

- Plastics: Waterman can be used to machine a variety of plastics, including ABS, PVC, and polycarbonate.

- Composites: Waterman can be used to machine a variety of composites, including fiberglass, carbon fiber, and Kevlar.

4. What are the different types of machining operations that can be performed using Waterman?

- Cutting: Waterman can be used to cut a variety of materials, including metals, plastics, and composites.

- Grinding: Waterman can be used to grind a variety of materials, including metals, plastics, and composites.

- Polishing: Waterman can be used to polish a variety of materials, including metals, plastics, and composites.

5. What are the advantages of using Waterman for machining?

- Waterman is a very versatile machine that can be used for a wide variety of machining operations.

- Waterman is a very precise machine that can produce very accurate results.

- Waterman is a very efficient machine that can save time and money.

6. What are the challenges of using Waterman for machining?

- Waterman can be a complex machine to operate, and it requires skilled operators to achieve the best results.

- Waterman can be a expensive machine to purchase and maintain.

- Waterman can be a noisy machine, and it can generate dust and debris.

7. What are the different types of maintenance that need to be performed on Waterman?

- Daily maintenance: Daily maintenance includes cleaning the machine, checking the fluid levels, and inspecting the components for wear and tear.

- Weekly maintenance: Weekly maintenance includes cleaning the machine more thoroughly, checking the calibration, and replacing any worn or damaged components.

- Monthly maintenance: Monthly maintenance includes a more comprehensive inspection of the machine, including checking the bearings, the motors, and the electrical system.

8. What are the different types of troubleshooting that can be performed on Waterman?

- Mechanical troubleshooting: Mechanical troubleshooting involves identifying and repairing any mechanical problems with the machine, such as problems with the bearings, the motors, or the electrical system.

- Electrical troubleshooting: Electrical troubleshooting involves identifying and repairing any electrical problems with the machine, such as problems with the wiring, the switches, or the control panel.

- Software troubleshooting: Software troubleshooting involves identifying and repairing any software problems with the machine, such as problems with the operating system, the application software, or the firmware.

9. What are the different types of training that are available for Waterman?

- Operator training: Operator training teaches operators how to operate the machine safely and efficiently.

- Maintenance training: Maintenance training teaches maintenance technicians how to maintain and repair the machine.

- Troubleshooting training: Troubleshooting training teaches operators and maintenance technicians how to troubleshoot and repair common problems with the machine.

10. What are the different types of documentation that are available for Waterman?

- User manual: The user manual provides instructions on how to operate the machine safely and efficiently.

- Maintenance manual: The maintenance manual provides instructions on how to maintain and repair the machine.

- Troubleshooting manual: The troubleshooting manual provides instructions on how to troubleshoot and repair common problems with the machine.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Waterman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Waterman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The role of a Waterman encompasses various tasks that directly impact the efficient and safe operation of a ship’s propulsion, auxiliary, and cargo systems. Key responsibilities include:

1. Machinery Operation and Maintenance

Watermen are responsible for the smooth operation and maintenance of a ship’s machinery, including engines, pumps, and other components.

- Monitor and adjust machinery settings to ensure optimal performance

- Perform minor repairs and troubleshoot problems to minimize downtime

2. Fuel and Water Management

Watermen oversee the management of fuel and water resources on the ship.

- Plan and coordinate fuel and water replenishment schedules

- Monitor fuel and water levels and maintain inventory records

3. Ballast Management

Watermen play a crucial role in ballast management, ensuring the ship’s stability and buoyancy.

- Plan and execute ballast water exchange operations

- Monitor ballast water levels and maintain proper distribution

4. Safety and Compliance

Watermen prioritize the safety of crew and passengers while upholding regulatory compliance.

- Implement and maintain safety procedures for machinery operation

- Adhere to environmental regulations and maritime laws

Interview Tips

Preparing thoroughly for a Waterman interview is crucial to showcase your skills and knowledge. Here are some valuable tips:

1. Research the Company and Position

Understanding the company’s operations, fleet, and market standing will help you tailor your answers and demonstrate your interest.

- Visit the company’s website and review their services, values, and recent news.

- Explore the position’s responsibilities and qualifications to highlight your relevant experience.

2. Practice Common Interview Questions

Anticipating typical interview questions allows you to prepare structured and confident responses.

- Prepare for questions about your experience in machinery operation, maintenance, and fuel management.

- Rehearse scenarios related to safety protocols, problem-solving, and teamwork.

3. Highlight Relevant Skills and Experiences

Emphasize your technical abilities, such as machinery troubleshooting, fuel optimization, and ballast water management.

- Quantify your accomplishments with specific figures and outcomes.

- Provide examples that showcase your attention to detail, problem-solving skills, and safety consciousness.

4. Demonstrate Enthusiasm and Passion

Convey your passion for the maritime industry and your eagerness to contribute to the company.

- Share anecdotes or examples that highlight your interest in watermen’s duties.

- Express your commitment to safety, efficiency, and environmental stewardship.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Waterman interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!