Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wave Soldering Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

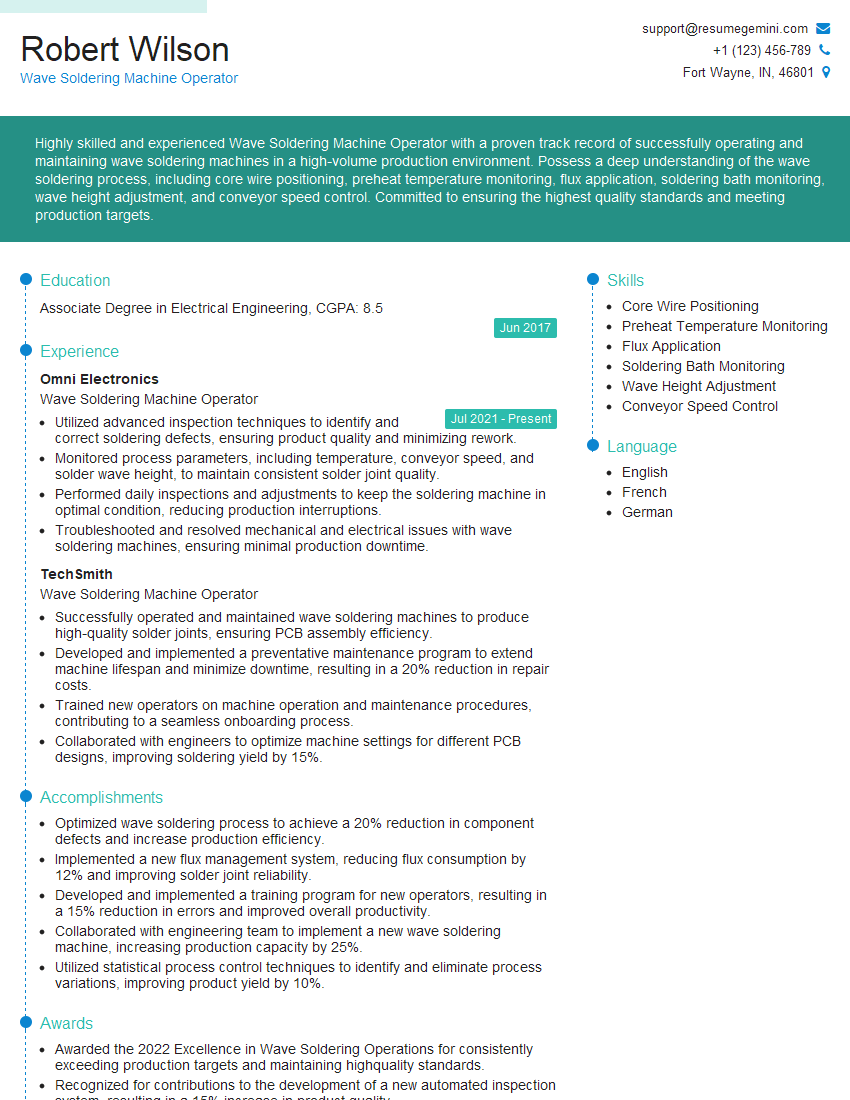

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wave Soldering Machine Operator

1. Describe the process of wave soldering?

Wave soldering is a mass soldering technique in which a printed circuit board (PCB) is passed over a wave of molten solder. The solder wave is created by a pump that forces molten solder up through a nozzle, creating a continuous wave. As the PCB passes over the wave, the solder flows up and over the surface of the board, wetting the metal surfaces of the components and forming solder joints.

2. What are the advantages of wave soldering?

Cost-effective

- Wave soldering is a cost-effective method of soldering, especially for high-volume production.

Efficient

- It is an efficient process, as it can solder multiple components simultaneously.

Reliable

- When properly set up and maintained, wave soldering can produce reliable solder joints.

3. What are the disadvantages of wave soldering?

- Wave soldering can be challenging to set up and maintain, and it requires specialized equipment.

- It is not suitable for all types of PCBs or components.

- Wave soldering can produce solder bridges and other defects if not properly controlled.

4. What are the key parameters to control in wave soldering?

- Solder temperature

- Wave height

- Conveyor speed

- Preheat temperature

- Flux type and application

5. How do you troubleshoot common wave soldering defects?

- Solder bridges: Caused by excessive solder flow, dirty flux, or misaligned components.

- Solder voids: Caused by insufficient solder flow, cold solder joints, or outgassing from the PCB.

- Solder balls: Caused by solder spattering from the wave or flux contamination.

- Poor wetting: Caused by dirty surfaces, insufficient preheat, or improper flux application.

6. What are the safety precautions to observe when operating a wave soldering machine?

- Wear appropriate protective clothing, including gloves, safety glasses, and a lab coat.

- Keep the work area clean and free of flammable materials.

- Never touch the molten solder or the wave soldering machine with bare hands.

- Be aware of the potential for solder spatter and take precautions to avoid injury.

7. How do you maintain a wave soldering machine?

- Clean the solder pot and wave nozzle regularly.

- Inspect the conveyor belt and tension it as needed.

- Calibrate the temperature controllers and wave height gauges.

- Lubricate the moving parts of the machine.

- Perform regular preventive maintenance to identify and resolve potential problems.

8. What are the different types of wave soldering fluxes?

- Water-soluble fluxes: These fluxes are the most common and are easily removed with water after soldering.

- Rosin fluxes: These fluxes are less corrosive than water-soluble fluxes but leave a residue that must be removed with a solvent.

- No-clean fluxes: These fluxes leave a residue that does not need to be removed, but they can be more difficult to work with.

9. What is the role of preheat in wave soldering?

- Preheat helps to remove moisture and contaminants from the PCB.

- It also helps to activate the flux and promote wetting of the solder.

10. How do you determine the optimal wave height for wave soldering?

- The optimal wave height is typically between 1.5 and 2.5 mm.

- It should be high enough to provide adequate solder coverage, but not so high that it causes solder spattering or bridging.

- The correct wave height is determined by the type of PCB, the components being soldered, and the solder alloy being used.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wave Soldering Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wave Soldering Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Wave Soldering Machine Operator is responsible for setting up, operating, and maintaining a wave soldering machine. This individual is also responsible for inspecting and testing printed circuit boards (PCBs) to ensure that they meet quality standards.

1. Set up and operate wave soldering machine

The operator is responsible for setting up the wave soldering machine according to the manufacturer’s specifications. This includes setting the temperature of the solder, the speed of the conveyor belt, and the height of the solder wave.

- Follows established procedures and work instructions to ensure the quality of the soldering process

- Monitors the machine during operation and makes adjustments as needed to maintain optimal performance

2. Inspect and test PCBs

The operator is responsible for inspecting and testing PCBs after they have been soldered. This includes visually inspecting the boards for defects, such as solder bridges, shorts, and opens. The operator also tests the boards to ensure that they meet electrical specifications.

- Visually inspects PCBs for defects such as solder bridges, shorts, and opens

- Tests PCBs to ensure that they meet electrical specifications

3. Maintain wave soldering machine

The operator is responsible for maintaining the wave soldering machine. This includes cleaning the machine, replacing worn parts, and calibrating the machine.

- Cleans the machine regularly to remove solder residue and other contaminants

- Replaces worn parts as needed to ensure the proper functioning of the machine

4. Other duties

The operator may also be responsible for performing other duties, such as training new operators, troubleshooting problems, and working with other members of the production team.

- Trains new operators on the safe and efficient operation of the wave soldering machine

- Troubleshoots problems with the wave soldering machine and takes corrective action

Interview Tips

To prepare for your interview for a Wave Soldering Machine Operator position, you should be familiar with the key job responsibilities. You should also be able to demonstrate your skills in operating and maintaining a wave soldering machine. You should also be prepared to answer questions about your experience in the electronics industry.

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn about their history, products, and services

- Read online reviews of the company to get an idea of its culture and work environment

2. Practice your answers to common interview questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- The STAR method stands for Situation, Task, Action, Result

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in operating and maintaining wave soldering machines. Be prepared to discuss your skills and experience in detail.

- Quantify your experience whenever possible

- For example, instead of saying “I have experience operating wave soldering machines,” you could say “I have operated a wave soldering machine for over five years, and I have produced over 100,000 PCBs during that time.”

4. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the company and the position. This will show that you are interested in the opportunity and that you are serious about getting the job.

- Some good questions to ask include:

- “What are the biggest challenges facing the company right now?”

- “What are the opportunities for advancement within the company?”

Next Step:

Now that you’re armed with the knowledge of Wave Soldering Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wave Soldering Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini