Feeling lost in a sea of interview questions? Landed that dream interview for Wax Pattern Coater but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wax Pattern Coater interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

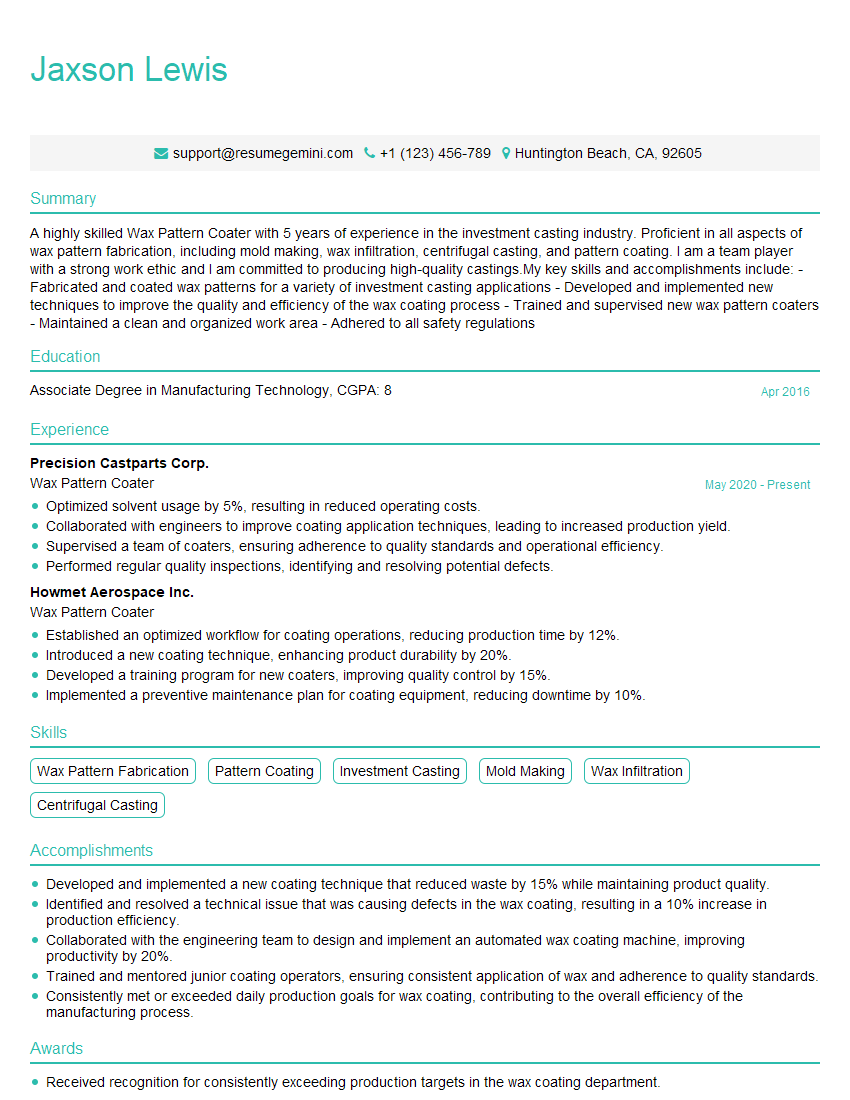

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wax Pattern Coater

1. Describe the process of wax pattern coating in lost-wax casting.

In lost-wax casting, wax pattern coating involves:

- Preparing the wax pattern by removing any imperfections.

- Applying a thin layer of primary slurry coat, typically composed of fine-grained ceramic, to create an initial bond between the pattern and the ceramic shell.

- Applying the backup coat, a coarser ceramic layer that supports the primary coat and provides thickness to the finished shell.

- Firing the shell to cure the ceramic and burn out the wax, leaving a negative mold of the original pattern.

2. What are the key properties of a good wax pattern for coating?

A good wax pattern for coating should possess the following properties:

- Dimensional accuracy: Accurate reproduction of the final part’s dimensions.

- Smooth surface: Minimizes defects and promotes proper coating adhesion.

- Free of defects: Avoids imperfections that could weaken the shell.

- Adequate strength: Withstands handling and coating without deformation.

- Meltability: Easily removable by burnout during the casting process.

3. Explain the difference between primary and backup slurry coats.

The primary slurry coat:

Characteristics:

- Fine-grained ceramic

- Thin layer

- Acts as a bonding agent

The backup coat:

Characteristics:

- Coarser ceramic

- Thicker layer

- Provides support and shell strength

4. What factors affect the quality of the ceramic shell?

Factors affecting shell quality include:

- Ceramic slurry composition

- Coating thickness

- Drying conditions

- Firing schedule

- Wax pattern preparation

5. Describe the role of binders in wax pattern coating slurries.

- Organic binders:

- Enhance particle suspension

- Increase slurry adhesion

- Control viscosity

- Inorganic binders:

- Provide strength to the fired shell

- Prevent cracking during burnout

6. How do you ensure the uniformity of the ceramic shell thickness?

- Using calibrated dipping or spraying equipment

- Controlling slurry viscosity and solids content

- Maintaining consistent drying and firing conditions

- Monitoring shell thickness using non-destructive testing methods

7. Describe the process of investing a wax pattern with ceramic slurry.

Investing involves:

- Suspending the wax pattern in a frame

- Dipping or spraying the pattern with primary slurry

- Applying multiple layers of backup slurry

- Drying the shell between coats

- Firing the shell to cure the ceramic and burn out the wax

8. What precautions should be taken when handling wax patterns before coating?

- Wear gloves to avoid contaminating the pattern.

- Handle patterns carefully to prevent damage.

- Store patterns in a cool, dry place to prevent deformation.

- Remove any excess wax or sprue material before coating.

9. How do you troubleshoot common problems encountered in wax pattern coating?

Troubleshooting common issues:

Problem: Poor adhesion of the ceramic shell

- Ensure proper wax pattern preparation

- Check the primary slurry composition

- Adjust dipping or spraying parameters

Problem: Cracking of the ceramic shell

- Check the firing schedule

- Adjust slurry viscosity

- Control drying conditions

Problem: Inconsistent shell thickness

- Calibrate coating equipment

- Maintain slurry properties

- Monitor drying and firing conditions

10. Explain the importance of quality control in wax pattern coating.

- Ensures dimensional accuracy and surface quality of final castings

- Prevents casting defects

- Reduces production delays and costs

- Maintains customer satisfaction and product reputation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wax Pattern Coater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wax Pattern Coater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wax Pattern Coaters are responsible for preparing wax patterns for use in the investment casting process. Their key responsibilities involve:

1. Wax Injection

Injecting molten wax into heated metal dies to form wax patterns

- Ensuring correct wax temperature and pressure

- Maintaining proper die alignment and temperature

2. Pattern Inspection

Inspecting wax patterns for defects, such as cracks, voids, and surface imperfections

- Using a variety of inspection methods, including visual inspection and dimensional checks

- Rejecting non-conforming patterns and repairing minor defects

3. Pattern Assembly

Assembling wax patterns into clusters or “trees” for investment casting

- Using jigs and fixtures to ensure proper alignment and spacing

- Attaching patterns to sprues and gates

4. Sprue and Gate Removal

Removing sprues and gates from wax patterns after investment casting

- Using manual or automated methods to remove material

- Smoothing edges and removing any residual wax

Interview Tips

Preparing thoroughly for an interview can increase your chances of a successful outcome. Here are some tips to help you ace your Wax Pattern Coater interview:

1. Research the Company and Position

Take the time to learn about the company’s history, values, and products. Familiarize yourself with the specific job description and identify your relevant skills and experience.

- Visit the company website and read any available information about the position.

- Research the industry and current trends to demonstrate your knowledge.

2. Practice Common Interview Questions

Prepare responses to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering in a clear and concise manner, highlighting your relevant qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Quantify your accomplishments whenever possible, using specific metrics and data.

3. Dress Professionally and Arrive Early

First impressions matter. Dress in appropriate business attire and arrive at the interview on time, if not a few minutes early. This shows respect for the interviewers and indicates your professionalism.

- Avoid wearing overly casual or revealing clothing.

- Allow yourself extra time to account for unexpected delays.

4. Be Confident and Enthusiastic

Show confidence in your abilities and enthusiasm for the position. Maintain eye contact, speak clearly and articulate, and demonstrate your interest in the company and the role.

- Be prepared to talk about your skills, experiences, and accomplishments.

- Ask thoughtful questions to show your engagement and interest.

5. Follow Up After the Interview

Within 24 hours of the interview, send a thank-you note to the interviewers. Express your appreciation for their time and reiterate your interest in the position. You can also use this opportunity to clarify any points or address any concerns that arose during the interview.

- Keep the note concise and professional.

- Mention specific aspects of the interview that you found interesting or relevant.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wax Pattern Coater, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wax Pattern Coater positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.