Are you gearing up for a career in Wax Pattern Repairer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wax Pattern Repairer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

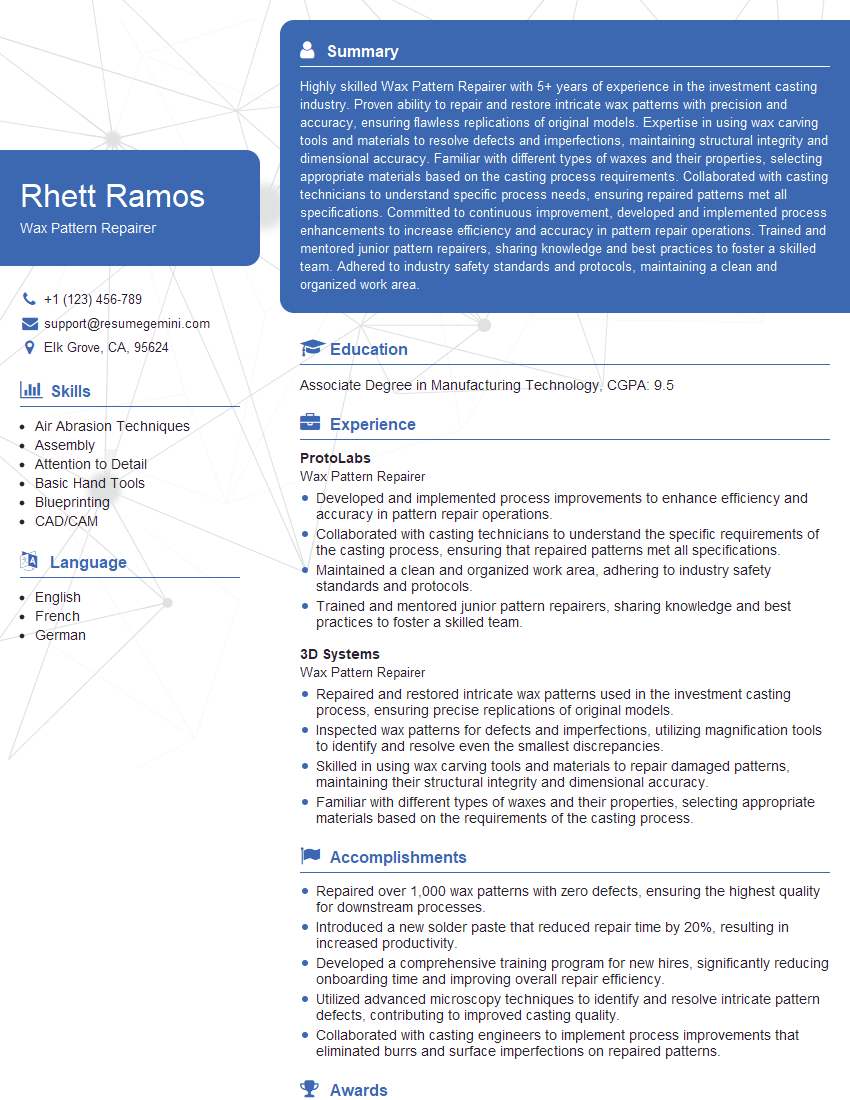

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wax Pattern Repairer

1. Explain the process of repairing a wax pattern?

The process of repairing a wax pattern involves several steps:

- Inspection: The first step is to inspect the wax pattern carefully to identify the damaged areas.

- Cleaning: The damaged area is cleaned using a suitable solvent to remove any contaminants.

- Preparation: The damaged area is prepared for repair by leveling the surface and removing any debris.

- Repair: The appropriate repair material is selected and applied to the damaged area using a heated tool or spatula.

- Finishing: Once the repair is complete, the area is smoothed and finished to restore the original shape and dimensions.

2. What are the different types of wax pattern defects and how do you identify them?

Types of defects:

- Cracks: Lines or breaks in the wax pattern caused by stress or mishandling.

- Voids: Empty spaces or holes in the wax pattern caused by trapped air or poor mold filling.

- Pinholes: Small holes in the wax pattern caused by air bubbles or impurities.

- Warpage: Distortion or bending of the wax pattern due to uneven shrinkage or temperature fluctuations.

- Sags or Runs: Irregularities in the wax pattern caused by excessive melting or poor support.

Identification:

- Visual inspection: Most defects can be identified by visually examining the wax pattern.

- Dimensional measurement: Warpage or other defects can be detected using calipers or a coordinate measuring machine (CMM).

- Non-destructive testing (NDT): Advanced techniques such as ultrasonic testing or magnetic particle testing can be used to identify hidden defects.

3. What materials and tools are used in wax pattern repair?

The following materials and tools are commonly used in wax pattern repair:

- Wax repair material: A wax-based material that matches the original wax formulation.

- Heated tool: A soldering iron, spatula, or hot air gun used to melt and apply the repair material.

- Solvent: A chemical cleaner used to remove contaminants from the damaged area.

- Brushes: Soft-bristled brushes used to apply or remove the repair material.

- Measuring tools: Calipers or a CMM used to ensure accurate repair dimensions.

- Safety equipment: Gloves, safety glasses, and a respirator to protect against fumes or molten wax.

4. What safety precautions should be taken while repairing wax patterns?

The following safety precautions should be observed:

- Use proper ventilation: Fumes from heated wax can be harmful, so ensure adequate ventilation in the work area.

- Wear protective gear: Use gloves, safety glasses, and a respirator to protect against molten wax and fumes.

- Handle heated tools with care: Heated tools can cause burns or fires, so handle them with utmost caution and use proper heat-resistant materials.

- Keep the work area clean: Clean up any spilled wax or solvents to prevent slipping or other accidents.

- Follow established procedures: Always follow established safety protocols and manufacturer’s instructions when using materials and equipment.

5. How do you ensure the quality of the repaired wax pattern?

To ensure quality, follow these steps:

- Inspection: Conduct a thorough visual inspection of the repaired area to ensure it meets the original specifications.

- Dimensional verification: Use measuring tools to verify that the dimensions of the repaired area are accurate.

- Leak testing: If the repaired wax pattern is intended for use in a casting process, perform leak testing to ensure it holds liquids without any defects.

- Documentation: Keep a record of the repair process, including the materials used, techniques applied, and any observations made.

6. Describe the importance of accurate temperature control in wax pattern repair.

Accurate temperature control is crucial for several reasons:

- Material properties: The viscosity and flow characteristics of wax are highly temperature-dependent, so controlled heating ensures proper application.

- Bonding strength: The bond between the repair material and the original wax depends on the temperature at which they are joined.

- Dimensional stability: Wax can expand or contract significantly with temperature changes, so controlled heating prevents distortion during repair.

- Safety: Overheating can cause wax to ignite or release harmful fumes, so temperature control ensures a safe working environment.

7. Explain the use of non-destructive testing (NDT) in wax pattern repair.

NDT techniques, such as ultrasonic testing or magnetic particle testing, are used to detect hidden defects or assess the integrity of the repaired wax pattern:

- Ultrasonic testing: Sound waves are transmitted through the wax pattern to identify internal voids or cracks.

- Magnetic particle testing: Magnetic particles are applied to the surface of the wax pattern to reveal any surface or subsurface defects.

- These techniques: complement visual inspection and dimensional verification to provide a comprehensive assessment of the repaired wax pattern.

8. How do you handle repairs on complex wax patterns with intricate details?

Repairing complex wax patterns requires special techniques:

- Careful handling: Delicate patterns require gentle handling to prevent damage during repair.

- Precision tools: Fine-tipped tools and brushes are used for precise application of repair material.

- Magnification: Magnifying lenses or microscopes aid in visualizing and repairing intricate details.

- Patience and skill: Complex repairs demand patience, attention to detail, and a high level of craftsmanship.

9. What are the common challenges faced in wax pattern repair?

Wax pattern repair presents several challenges:

- Material characteristics: Wax is a soft and delicate material that can be easily damaged or distorted.

- Precision: Repairs require precision to maintain the original dimensions and details of the wax pattern.

- Time constraints: Repairing wax patterns can be time-consuming, especially for complex or large patterns.

- Safety hazards: Fumes from heated wax and the use of sharp tools pose safety risks.

10. How do you stay updated with the latest techniques and materials in wax pattern repair?

To stay current in the field, I follow these practices:

- Industry publications: I subscribe to trade journals and industry magazines to stay informed about advancements in wax pattern repair techniques and materials.

- Conferences and workshops: I attend industry events and workshops to learn about new technologies and best practices.

- Manufacturer training: I seek training opportunities provided by manufacturers of wax repair materials and equipment.

- Online resources: I utilize online forums, webinars, and technical articles to expand my knowledge and stay connected with the industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wax Pattern Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wax Pattern Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wax Pattern Repairers are responsible for repairing and maintaining wax patterns used in the production of investment castings. Their duties involve identifying and fixing defects in wax patterns, ensuring the patterns meet the required specifications.

1. Pattern Inspection and Repair

Inspect wax patterns for defects such as cracks, voids, and surface imperfections.

- Use hand tools and specialized equipment to repair defects in wax patterns.

- Ensure repaired patterns meet dimensional accuracy and surface finish specifications.

2. Wax Injection and Mold Preparation

Prepare wax injection molds and inject wax into the molds to create wax patterns.

- Maintain a clean and organized work area to minimize contamination.

- Follow established procedures to ensure the proper mixing and injection of wax.

3. Casting and Molding

Assist in the casting and molding processes to produce investment castings.

- Prepare investment slurry and apply it to wax patterns to create ceramic molds.

- operate and maintain casting equipment to produce metal castings.

4. Quality Control and Inspection

Inspect finished castings for defects and ensure they meet quality standards.

- Use measuring and testing equipment to verify dimensional accuracy and surface finish.

- Document and report any defects or nonconformances to supervisors.

Interview Tips

To ace the interview for a Wax Pattern Repairer position, follow these tips:

1. Research the Company and Industry

Learn about the company’s casting processes, products, and reputation within the industry. This knowledge will demonstrate your interest and preparation.

- Visit the company website and review their product line and customer testimonials.

- Research industry trends and advancements to showcase your understanding of the field.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in wax pattern repair techniques, mold preparation, and casting processes. Highlight any experience in quality control or defect analysis.

- Quantify your accomplishments, using specific examples to demonstrate your impact.

- Demonstrate your attention to detail and meticulousness to convey your suitability for the role.

3. Prepare for Technical Questions

Anticipate technical questions related to wax pattern repair, casting techniques, and quality control standards.

- Review common defects in wax patterns and their repair methods.

- Understand the different casting processes and the factors that affect casting quality.

4. Practice Your Communication Skills

Demonstrate your ability to communicate clearly and concisely, both verbally and in writing. Highlight your teamworking and problem-solving abilities.

- Prepare for behavioral questions by recalling instances where you successfully resolved issues or collaborated with others.

- Practice answering preguntas in a structured manner, using the STAR method (Situation, Task, Action, Result).

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wax Pattern Repairer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.