Are you gearing up for a career in Web Offset Press Feeder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Web Offset Press Feeder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

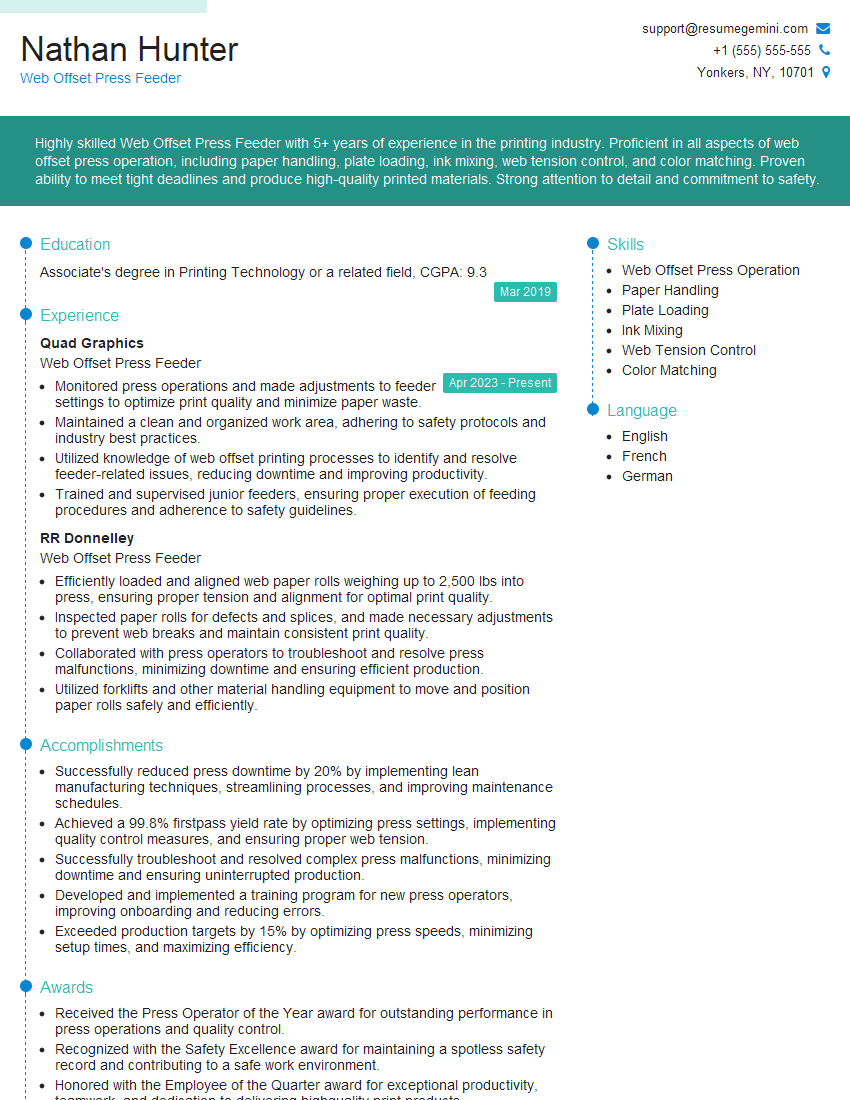

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Web Offset Press Feeder

1. Explain your knowledge about web offset press printing?

- Web offset press printing is a type of offset printing that uses a continuous roll of paper instead of individual sheets.

- The paper is fed through the press from a roll, and the ink is transferred to the paper from a series of rollers.

- Web offset press printing is used to produce large quantities of printed materials, such as newspapers, magazines, and catalogs.

2. What are the major components of a web offset press?

- The main components of a web offset press include the infeed, the printing units, the dryer, and the folder.

- The infeed feeds the paper into the press.

- The printing units transfer the ink to the paper.

- The dryer dries the ink on the paper.

- The folder folds the paper into the desired format.

3. What are the different types of web offset presses?

- The different types of web offset presses include heatset, coldset, and non-heatset presses.

- Heatset presses use heat to dry the ink, while coldset presses use cold air.

- Non-heatset presses do not use heat to dry the ink.

4. What are the common problems that can occur on a web offset press?

- The common problems that can occur on a web offset press include paper jams, ink problems, and printing defects.

- Paper jams can be caused by a variety of factors, such as неправильный trimming of the paper or a buildup of paper dust in the press.

- Ink problems can be caused by a variety of factors, such as the неправильное соотношение of ink to water or the use of неправильный inks.

- Printing defects can be caused by a variety of factors, such as a dirty press or a неправильная adjustment of the press.

5. What are the safety precautions that must be followed when operating a web offset press?

- The safety precautions that must be followed when operating a web offset press include wearing proper clothing, keeping hands away from moving parts, and following all safety procedures.

- Proper clothing includes long pants, a long-sleeved shirt, and closed-toe shoes.

- Hands should be kept away from moving parts, such as the rollers and the gears.

- All safety procedures must be followed, such as locking out the press before performing maintenance.

6. What are the maintenance procedures that must be performed on a web offset press?

- The maintenance procedures that must be performed on a web offset press include cleaning the press, lubricating the press, and adjusting the press.

- Cleaning the press removes dirt and debris from the press.

- Lubricating the press keeps the press running smoothly.

- Adjusting the press ensures that the press is printing correctly.

7. What are the quality control procedures that must be followed when operating a web offset press?

- The quality control procedures that must be followed when operating a web offset press include inspecting the paper, inspecting the ink, and inspecting the printed product.

- Inspecting the paper ensures that the paper is the correct type and size.

- Inspecting the ink ensures that the ink is the correct color and consistency.

- Inspecting the printed product ensures that the product is free of defects.

8. What are the environmental regulations that must be followed when operating a web offset press?

- The environmental regulations that must be followed when operating a web offset press include managing waste, reducing emissions, and conserving energy.

- Managing waste includes properly disposing of waste ink and paper.

- Reducing emissions includes using low-VOC inks and installing emission control devices.

- Conserving energy includes turning off the press when not in use and using energy-efficient lighting.

9. What are the future trends in web offset printing?

- The future trends in web offset printing include the use of digital printing, the use of new materials, and the development of new printing technologies.

- Digital printing is a type of printing that uses a digital file to create a printed image.

- New materials are being developed that are more sustainable and can be printed on with offset presses.

- New printing technologies are being developed that are more efficient and can produce higher-quality printed products.

10. How do you ensure that the paper is properly tensioned on the press?

- I use a tension meter to measure the tension of the paper.

- I adjust the tension knobs on the press to achieve the desired tension.

- I monitor the tension of the paper throughout the printing process to ensure that it remains consistent.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Web Offset Press Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Web Offset Press Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Web Offset Press Feeders are responsible for ensuring a smooth and efficient printing process by feeding paper into the press and monitoring the machine. Their key job responsibilities include:

1. Paper Handling

Loading, aligning, and feeding paper rolls into the press.

- Inspecting paper for defects or damage before loading.

- Adjusting paper tension and alignment to prevent jams or misfeeds.

2. Machine Operation

Monitoring the press during operation, checking for any irregularities or malfunctions.

- Adjusting press settings as needed to maintain optimal print quality.

- Performing routine maintenance and troubleshooting minor issues.

3. Quality Control

Inspecting printed materials for defects or errors, and reporting any issues to the press operator.

- Maintaining a clean and organized work area to minimize print errors.

- Adhering to safety regulations and following proper work procedures.

4. Communication

Communicating effectively with the press operator and other team members to ensure a coordinated workflow.

- Reporting any concerns or observations to the supervisor or manager.

- Providing guidance and training to new team members.

Interview Tips

To ace the interview for a Web Offset Press Feeder position, it is crucial to be well-prepared and demonstrate your skills and knowledge. Here are some tips to help you succeed:

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for. This will enable you to tailor your answers to the interviewer’s questions and demonstrate your interest in the position.

- Look into the company’s website, social media pages, and industry reports.

- Read the job description carefully and identify the key requirements and responsibilities.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are relevant to the job responsibilities. Provide specific examples and quantifiable results whenever possible.

- Discuss your experience in paper handling, machine operation, and quality control.

- Highlight any training or certifications you have received in these areas.

3. Demonstrate Your Attention to Detail

Web Offset Press Feeders must be highly attentive to detail to ensure the accuracy and quality of printed materials. During the interview, emphasize your ability to spot errors and ensure precision in your work.

- Share examples of how you have maintained high standards in previous roles.

- Explain how you handle tasks that require meticulous attention.

4. Show Your Communication Skills

Effective communication is crucial for success in this role. Highlight your ability to communicate clearly and effectively with both superiors and colleagues.

- Provide examples of how you have successfully resolved issues or provided feedback.

- Discuss your experience in working as part of a team and collaborating with others.

5. Prepare for Common Interview Questions

Familiarize yourself with common interview questions and prepare your answers in advance. This will help you feel more confident and organized during the interview.

- Practice answering questions about your experience, skills, and motivations.

- Consider preparing questions to ask the interviewer about the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Web Offset Press Feeder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!