Are you gearing up for a career in Weigh Boss? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Weigh Boss and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

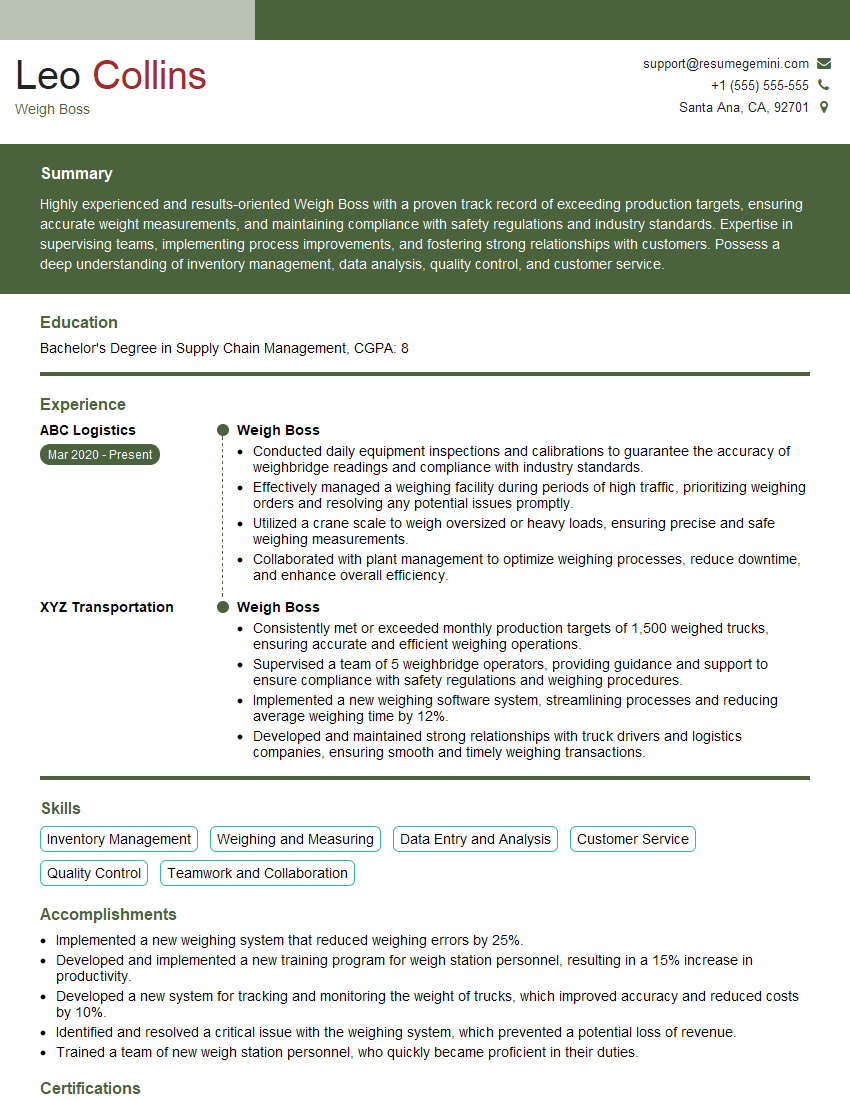

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Weigh Boss

1. Can you explain the process of calibrating a scale?

- The process of calibrating a scale involves adjusting it to ensure it provides accurate weight measurements.

- Typically, a known weight (called a calibration weight) is placed on the scale, and the scale is adjusted until it displays the correct weight.

- The calibration process may involve using a calibration knob or a software interface.

- Calibration is important to ensure the accuracy of the weighing results, as even minor deviations can affect the reliability of the measurements.

2. What are the different types of scales used in the industry?

Analog Scales

- Use a mechanical lever and spring system to indicate weight.

- Simple to use and relatively inexpensive.

- Not as accurate or precise as digital scales.

Digital Scales

- Use a load cell to measure weight and display the result digitally.

- More accurate and precise than analog scales.

- Often have additional features such as tare, hold, and unit conversion.

Platform Scales

- Designed to weigh large or heavy items.

- Typically have a flat platform where the item is placed for weighing.

- Can measure weight in a range of units.

Crane Scales

- Used to weigh suspended loads.

- Attached to a crane or hoist.

- Can measure weight remotely.

3. What are the key factors to consider when selecting a scale for a specific application?

- Capacity: The maximum weight the scale can measure.

- Accuracy: The level of precision the scale provides.

- Resolution: The smallest weight increment that the scale can display.

- Type of scale: Analog or digital, platform, crane, etc.

- Features: Additional capabilities such as tare, hold, unit conversion, etc.

- Environmental conditions: Where the scale will be used and any special requirements.

- Cost: The budget for purchasing and maintaining the scale.

4. What are the common errors that can occur when using a scale?

- Incorrect calibration: The scale may not be properly calibrated, leading to inaccurate readings.

- Overloading: Weighing an item that exceeds the scale’s capacity can damage the scale and produce incorrect measurements.

- Environmental factors: Extreme temperatures, vibrations, or magnetic fields can affect the scale’s accuracy.

- Improper placement: The scale should be placed on a stable, level surface to ensure accurate readings.

- Human error: Mistakes in reading or recording the weight can lead to incorrect results.

5. How do you maintain and troubleshoot a scale to ensure its accuracy and reliability?

- Regular calibration: Calibrate the scale regularly to maintain its accuracy.

- Cleaning: Keep the scale clean to prevent dirt and debris from affecting its performance.

- Inspection: Periodically inspect the scale for any physical damage or loose parts.

- Troubleshooting: If the scale is not functioning correctly, troubleshoot the issue by checking the power supply, connections, and display.

- Repairs: If necessary, contact a qualified technician to repair any malfunctioning components.

6. Describe the legal requirements and regulations related to the use of scales in commercial settings.

- In many jurisdictions, scales used in commercial transactions must meet certain legal requirements to ensure accuracy and fairness.

- These requirements may include regular inspections and certifications by government agencies.

- Failure to comply with legal regulations can result in fines or penalties.

- It is important to be aware of the specific requirements in your area and to ensure that your scales are compliant.

7. How do you ensure the traceability of weighing results in a quality control environment?

- Traceability refers to the ability to track the history and origin of weighing results.

- This is important in quality control to ensure the reliability and integrity of the measurements.

- Traceability can be achieved through documentation, calibration records, and using scales that meet specific standards.

- By maintaining traceability, you can demonstrate the validity of your weighing results and meet regulatory requirements.

8. How do you handle customer complaints or disputes related to weighing accuracy?

- When handling customer complaints, it is important to remain professional and empathetic.

- Listen attentively to the customer’s concerns and try to understand their perspective.

- Verify the accuracy of the scale by re-weighing the item or performing a calibration check.

- If the scale is found to be inaccurate, recalibrate or repair it as necessary.

- Communicate clearly with the customer and explain the steps taken to resolve the issue.

9. Describe your experience with using statistical process control (SPC) techniques in weighing operations.

- Statistical process control (SPC) techniques are used to monitor and improve the stability and accuracy of weighing processes.

- These techniques involve collecting and analyzing data to identify and eliminate sources of variation.

- SPC tools such as control charts can help identify trends, patterns, and special causes of variation in weighing results.

- By implementing SPC, you can optimize your weighing processes, reduce errors, and improve the overall quality of your measurements.

10. How do you stay up-to-date with advancements in weighing technology and best practices?

- To stay up-to-date with advancements in weighing technology and best practices, I regularly engage in the following activities:

- Attend industry conferences and webinars.

- Read technical journals and articles.

- Participate in online forums and discussions.

- Consult with experts in the field.

- By staying current with the latest developments, I can ensure that I am using the most effective weighing techniques and technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Weigh Boss.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Weigh Boss‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Weigh Boss is responsible for overseeing the weighing operations of a facility, ensuring accuracy and efficiency in weighing and recording the weight of materials or products. The key job responsibilities include:1. Managing Weighing Operations

Directly supervising weighing crews and ensuring they adhere to established weighing procedures.

- Assign staff to weighing stations and provide necessary instructions.

- Monitor crew performance and provide feedback to improve accuracy and efficiency.

2. Maintaining Equipment

Calibrating and maintaining weighing equipment to ensure accuracy and compliance with industry standards.

- Conduct regular equipment inspections and maintenance tasks.

- Coordinate repairs or replacements as needed.

3. Data Management

Recording and maintaining accurate weight data in a timely manner.

- Record weights using manual or automated systems.

- Generate reports and summaries as required.

4. Quality Control

Establishing and implementing quality control measures to ensure the accuracy and consistency of weighing operations.

- Develop and document standard operating procedures (SOPs) for weighing.

- Conduct regular audits to ensure compliance with SOPs.

Interview Tips

1. Research the Company and Position

Familiarize yourself with the company’s website, industry news, and the specific requirements of the Weigh Boss position.

- Identify keywords and skills mentioned in the job description and highlight them in your resume and cover letter.

- Prepare questions to ask the interviewer about the company’s weighing operations and quality control processes.

2. Quantify Your Experience and Skills

Use specific numbers and metrics to demonstrate your accomplishments in previous weighing or quality control roles.

- Provide examples of how you improved weighing accuracy, reduced errors, or enhanced efficiency.

- Emphasize your experience in calibrating and maintaining weighing equipment, as well as your knowledge of industry regulations.

3. Highlight Your Problem-Solving and Decision-Making Abilities

Share instances where you faced challenges in weighing operations and how you resolved them effectively.

- Describe situations where you analyzed data, identified trends, and implemented solutions to improve weighing accuracy or quality.

- Demonstrate your ability to prioritize tasks, manage multiple responsibilities, and make sound judgments.

4. Be Enthusiastic and Professional

Show genuine interest in the position and the company.

- Convey your passion for ensuring accuracy and quality in weighing operations.

- Maintain a professional demeanor throughout the interview and dress appropriately.

- Thank the interviewer for their time and follow up with a thank-you note.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Weigh Boss interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.