Feeling lost in a sea of interview questions? Landed that dream interview for Weigher and Mixer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Weigher and Mixer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

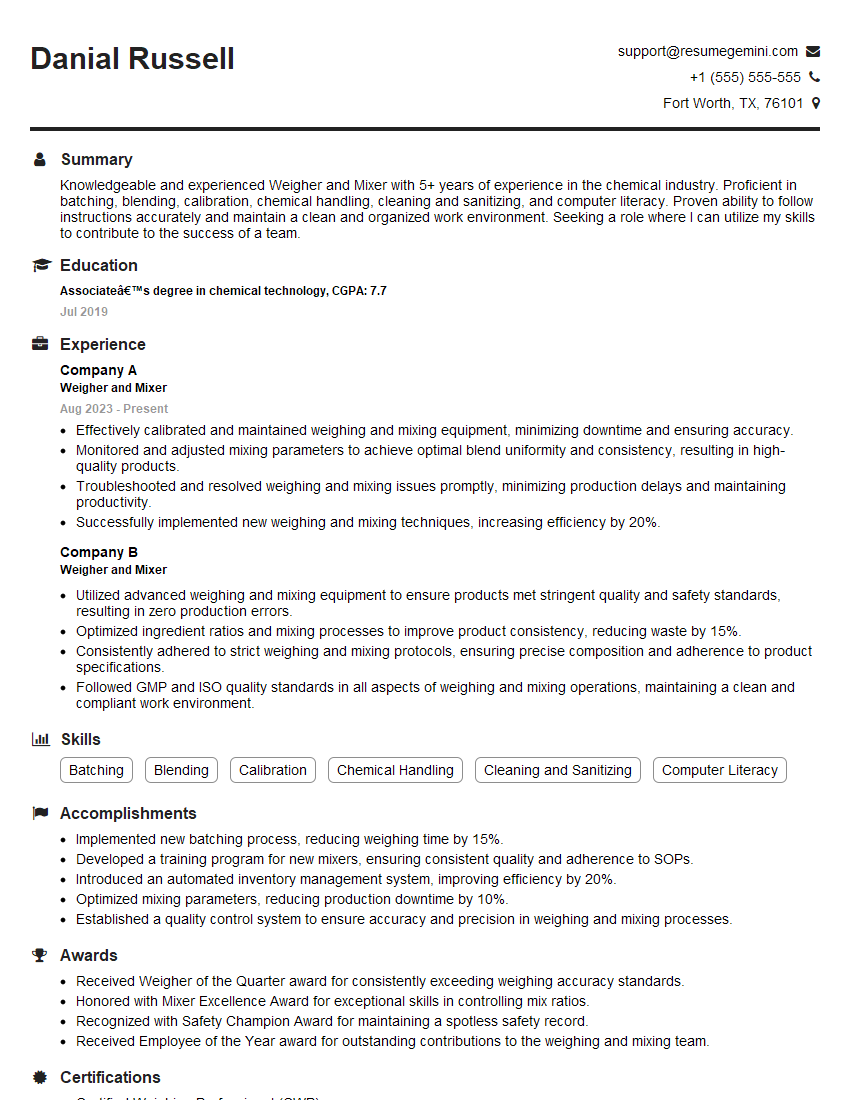

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Weigher and Mixer

1. How do you ensure accurate weighing and mixing of ingredients?

To ensure accurate weighing and mixing of ingredients, I follow these key steps:

- Calibrate weighing scales and mixers regularly to maintain precision.

- Adhere to established recipes and specifications to guarantee correct proportions.

- Use proper weighing techniques like double-checking measurements to minimize errors.

- Pay attention to environmental factors such as temperature and humidity that can affect weighing accuracy.

- Frequently monitor the mixing process to ensure uniform distribution of ingredients.

2. Describe the process of calibrating a weighing scale.

Weighing Scale Calibration Process:

- Preparation: Gather necessary tools like calibration weights and a calibration certificate.

- Warm-Up: Allow the scale to stabilize for an optimal period before calibration.

- Test Mode: Access the scale’s calibration mode and follow its specific instructions.

- Calibration Weights: Place certified calibration weights on the scale in ascending order.

- Adjustment: Adjust the scale’s internal settings to match the weight readings.

- Verification: After calibration, verify the scale’s accuracy using different weights.

- Documentation: Record the calibration details for future reference and traceability.

Mixer Calibration Process:

- Speed Calibration: Use a tachometer to measure the mixer’s speed and adjust it to specified levels.

- Temperature Calibration: Monitor the mixer’s temperature and calibrate probes to ensure accurate temperature readings.

- Torque Calibration: Check and adjust the mixer’s torque settings using calibrated torque wrenches.

3. How do you handle discrepancies between the desired and actual weight or mix?

When discrepancies occur, I take the following steps:

- Reweigh or remix the ingredients to confirm the accuracy of the initial measurement.

- Check the calibration of the weighing scale or mixer to rule out equipment errors.

- Thoroughly inspect the ingredients for any foreign objects or contamination that may affect weight.

- Consult with supervisors or quality control personnel to determine the root cause and appropriate corrective actions.

- Document the discrepancy and any corrective measures taken for traceability and accountability.

4. What safety measures do you follow when operating weighing and mixing equipment?

To ensure a safe work environment, I adhere to these safety practices:

- Wear appropriate personal protective equipment such as gloves and safety glasses.

- Operate equipment only when authorized and after receiving proper training.

- Keep the work area clean and free from tripping hazards or spills.

- Never overload weighing scales or mixers beyond their capacity.

- Follow established lockout/tagout procedures when servicing or repairing equipment.

- Report any equipment malfunctions or safety concerns promptly to supervisors.

5. How do you maintain hygiene and sanitation standards in your work area?

Maintaining hygiene and sanitation is crucial. I follow these practices:

- Clean and sanitize all equipment and work surfaces before and after each use.

- Wear clean gloves and aprons to prevent contamination.

- Store ingredients properly to prevent spoilage or contamination.

- Dispose of waste and cleaning materials appropriately.

- Follow established sanitation protocols and adhere to all applicable regulations.

6. What types of scales and mixers are you familiar with?

I am proficient in operating the following types of scales and mixers:

Scales:

- Mechanical Scales

- Electronic Scales

- Platform Scales

- Analytical Scales

Mixers:

- Ribbon Mixers

- Paddle Mixers

- Dough Mixers

- Extruders

7. How do you calculate the theoretical yield of a mixed product?

To calculate the theoretical yield, I follow this formula:

Theoretical Yield = (Mass of Ingredient A / Purity of Ingredient A) + (Mass of Ingredient B / Purity of Ingredient B) + …

Where:

- Mass of Ingredient = Measured weight of the ingredient

- Purity of Ingredient = Percentage of active ingredient in the ingredient

8. What quality control procedures do you implement to ensure the accuracy and consistency of your work?

I implement the following quality control procedures:

- Regularly calibrate weighing scales and mixers to maintain precision.

- Follow standardized weighing and mixing protocols to minimize errors.

- Conduct in-process checks to verify accuracy and consistency.

- Monitor and document environmental conditions that can affect weighing and mixing.

- Keep detailed records of all weighing and mixing activities for traceability.

9. How do you handle rush orders or unexpected changes in production schedules?

To manage rush orders or schedule changes, I prioritize tasks and adjust my workflow as follows:

- Communicate with supervisors to understand the urgency and requirements.

- Reprioritize tasks and allocate resources to complete rush orders on time.

- Work overtime or adjust my schedule if necessary to meet deadlines.

- Stay flexible and adaptable to accommodate changes in production schedules.

- Inform supervisors of any potential delays or challenges to ensure timely delivery.

10. What are your strengths and weaknesses as a Weigher and Mixer?

Strengths:

- Exceptional attention to detail and accuracy.

- Proficient in using various weighing and mixing equipment.

- Strong knowledge of quality control procedures.

- Ability to work independently and as part of a team.

- Excellent communication and interpersonal skills.

Weaknesses:

- Can be overly focused on meeting accuracy standards, potentially slowing down the process at times.

- May need additional training on advanced mixing techniques for specific products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Weigher and Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Weigher and Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Weigher and Mixer is responsible for the accurate weighing, measuring, and mixing of ingredients in the production process. They also ensure that all materials are handled and stored in a safe and efficient manner.

1. Weighing and Measuring Ingredients

Weigh and measure ingredients according to specified recipes or formulations using various weighing and measuring equipment, such as scales, balances, volumetric dispensers, and graduated cylinders.

- Follow established weighing and measuring procedures to ensure accuracy and consistency.

- Record weights and measurements accurately in designated logs or electronic systems.

2. Mixing Ingredients

Mix ingredients thoroughly using appropriate mixing equipment, such as mixers, blenders, or agitators, to achieve the desired consistency and uniformity.

- Follow established mixing procedures to ensure proper blending and prevent contamination.

- Monitor mixing processes and make adjustments as needed to ensure desired results.

3. Quality Control

Conduct quality control checks on ingredients and finished products to ensure they meet specifications.

- Use appropriate testing methods, such as visual inspection, moisture analysis, or pH testing, to assess quality.

- Report any deviations from specifications to supervisors or quality control personnel.

4. Material Handling and Storage

Handle and store ingredients and materials in a safe and efficient manner.

- Use proper lifting techniques and equipment to move heavy or bulky materials.

- Follow established storage procedures to prevent contamination, spoilage, or damage.

Interview Tips

Preparation is key to acing any interview. Here are some tips to help you prepare for your interview for a Weigher and Mixer position:

1. Research the Company and Role

Take the time to learn about the company you’re applying to and the specific role you’re interested in. This will help you understand the company’s culture, values, and what they’re looking for in a candidate.

- Visit the company’s website to learn about their products, services, and mission.

- Read industry news and articles to stay up-to-date on the latest trends and developments.

2. Practice Your Answers

Once you’ve done your research, take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Prepare for questions about your experience, skills, and qualifications.

- Practice answering questions about your knowledge of the industry and the company.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- For men, a suit or dress pants and a button-down shirt are always a good choice.

- For women, a skirt or dress suit, or dress pants and a blouse are appropriate.

4. Be Punctual

Punctuality shows that you respect the interviewer’s time. Plan to arrive at the interview location 10-15 minutes early so you have time to check in and prepare yourself.

- If you’re running late, call or email the interviewer to let them know.

- Don’t be afraid to ask for directions if you get lost.

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest about your experience and qualifications.

- Show the interviewer your enthusiasm for the role and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Weigher and Mixer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.