Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Weight Tester interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Weight Tester so you can tailor your answers to impress potential employers.

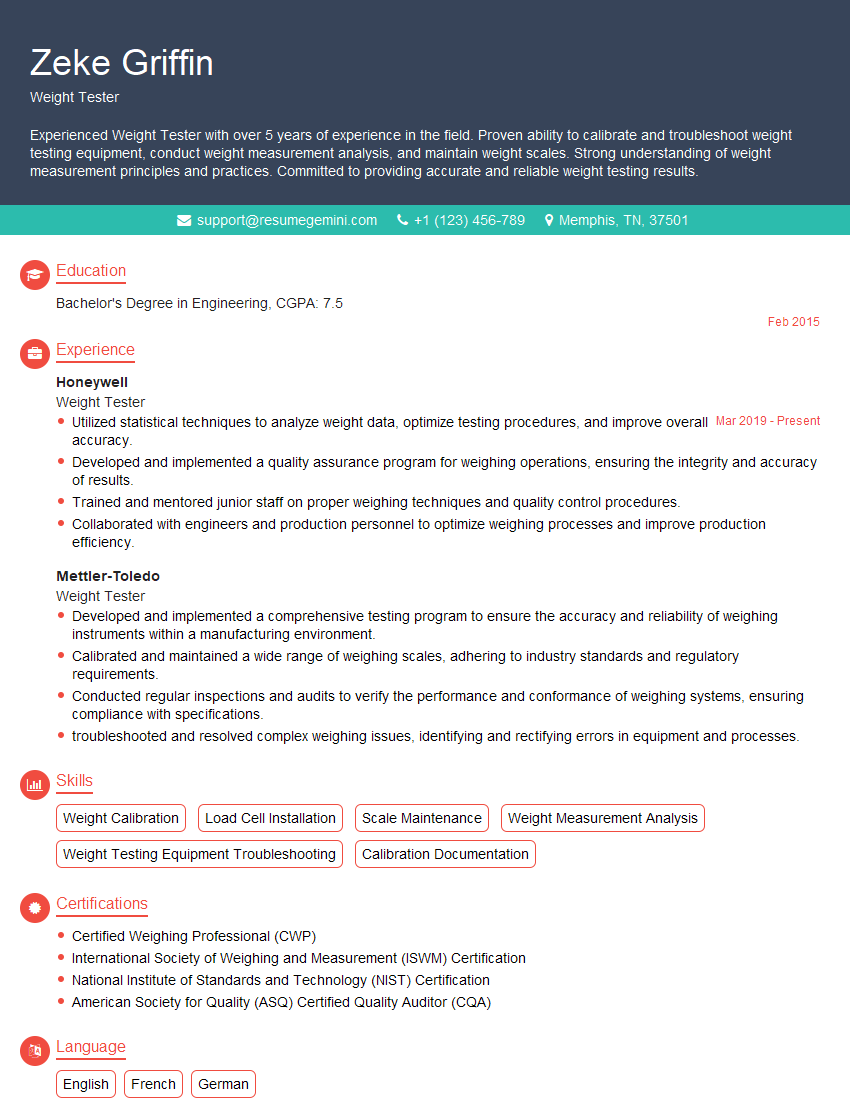

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Weight Tester

1. Describe the calibration process for a digital weight tester.

The calibration process for a digital weight tester involves the following steps:

- Clean the weight tester and remove any debris or foreign objects.

- Place the weight tester on a stable, level surface.

- Load a known weight onto the weight tester.

- Adjust the weight tester’s display to read the correct weight.

- Repeat steps 3 and 4 for several different weights.

- Record the weight tester’s readings in a calibration log.

2. What are the different types of weight testers available?

Mechanical weight testers

- Use a mechanical lever system to measure weight.

- Are typically used for weighing large, heavy objects.

- Are less accurate than digital weight testers.

Electronic weight testers

- Use a strain gauge or load cell to measure weight.

- Are typically used for weighing small, light objects.

- Are more accurate than mechanical weight testers.

3. What are the advantages and disadvantages of using a digital weight tester over a mechanical weight tester?

Advantages of digital weight testers:

- More accurate than mechanical weight testers.

- Easier to read than mechanical weight testers.

- Can be used to weigh a wider range of objects.

- More portable than mechanical weight testers.

Disadvantages of digital weight testers:

- More expensive than mechanical weight testers.

- Require batteries or a power source to operate.

- Can be less durable than mechanical weight testers.

4. What are the key factors to consider when selecting a weight tester?

The key factors to consider when selecting a weight tester include:

- The type of objects you will be weighing.

- The accuracy you need.

- The portability you need.

- The cost.

5. How do you troubleshoot a weight tester that is not giving accurate readings?

There are several things you can do to troubleshoot a weight tester that is not giving accurate readings:

- Check the weight tester’s calibration.

- Clean the weight tester.

- Inspect the weight tester for any damage.

- Contact the manufacturer of the weight tester for assistance.

6. What are the safety precautions that should be taken when using a weight tester?

The safety precautions that should be taken when using a weight tester include:

- Do not overload the weight tester.

- Do not use the weight tester in a wet or dusty environment.

- Do not drop the weight tester.

- Do not attempt to repair the weight tester yourself.

7. What are the different types of weighing scales available?

The different types of weighing scales available include:

- Mechanical scales

- Electronic scales

- Digital scales

- Platform scales

- Crane scales

- Truck scales

8. What are the key factors to consider when selecting a weighing scale?

The key factors to consider when selecting a weighing scale include:

- The capacity of the scale

- The accuracy of the scale

- The readability of the scale

- The portability of the scale

- The cost of the scale

9. How do you calibrate a weighing scale?

The calibration process for a weighing scale varies depending on the type of scale. However, the general steps involved in calibrating a weighing scale are as follows:

- Clean the weighing scale.

- Place the weighing scale on a stable, level surface.

- Load a known weight onto the weighing scale.

- Adjust the weighing scale’s display to read the correct weight.

- Repeat steps 3 and 4 for several different weights.

- Record the weighing scale’s readings in a calibration log.

10. What are the most common problems that can occur with weighing scales?

The most common problems that can occur with weighing scales include:

- Inaccurate readings

- Drifting readings

- Zero errors

- Mechanical problems

- Electrical problems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Weight Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Weight Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Weight Testers are responsible for ensuring the accuracy of weighing systems used in various industries. They perform a range of tasks to maintain and calibrate scales and other weighing devices.

1. Testing and Calibration

Weight Testers perform regular testing and calibration of weighing systems to ensure they meet industry standards and regulations. They use standard weights to verify the accuracy of scales and identify any deviations.

- Conducting periodic testing of weighing systems using certified weights

- Calibrating scales to meet specified accuracy requirements

2. Maintenance and Repair

They also perform maintenance and repair tasks on weighing systems. They inspect components, replace worn parts, and troubleshoot any issues to ensure optimal performance.

- Inspecting weighing systems for wear and damage

- Replacing defective components and repairing system malfunctions

3. Documentation and Reporting

Weight Testers maintain detailed records of all testing, calibration, and maintenance activities. They prepare reports and provide recommendations to ensure the accuracy and reliability of weighing systems.

- Documenting calibration results and maintenance activities

- Preparing reports on weighing system performance and recommendations

4. Compliance and Standards

Weight Testers must be familiar with industry regulations and standards related to weighing systems. They ensure that the systems they work on comply with these standards and regulations.

- Maintaining knowledge of industry regulations and standards

- Ensuring that weighing systems meet legal and regulatory requirements

Interview Tips

To ace an interview for a Weight Tester position, it is important to demonstrate your technical knowledge and skills, as well as your attention to detail and commitment to accuracy. Here are a few tips to help you prepare for your interview.

1. Research the Company and Position

Before the interview, take some time to research the company and the specific Weight Tester position. This will give you a better understanding of the company’s culture, goals, and the specific responsibilities of the role.

- Visit the company’s website to learn about their history, products, and services.

- Read any available job descriptions or company news articles to get a better sense of the company’s culture and values.

2. Practice Your Technical Skills

Weight Testers need to have a strong understanding of weighing systems, calibration techniques, and industry regulations. Prepare for the interview by practicing your technical skills. You may want to review the following concepts:

- Types of weighing systems and their applications

- Calibration methods and procedures

- Industry regulations and standards for weighing systems

3. Prepare Examples of Your Work

During the interview, you may be asked to provide examples of your work. Be prepared to discuss specific projects or tasks that you have completed that demonstrate your skills and abilities as a Weight Tester.

- Describe a time when you successfully calibrated a weighing system to meet industry standards.

- Explain how you troubleshoot and repair a malfunctioning weighing system.

4. Be Punctual and Professional

Punctuality and professionalism are important for any job interview, but they are especially important for a Weight Tester position. As a Weight Tester, you will be responsible for ensuring the accuracy and reliability of weighing systems. Your punctuality and professionalism will demonstrate your commitment to quality and attention to detail.

- Arrive for your interview on time, or even a few minutes early.

- Dress professionally and be well-groomed.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Weight Tester role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.