Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Weld Fitter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

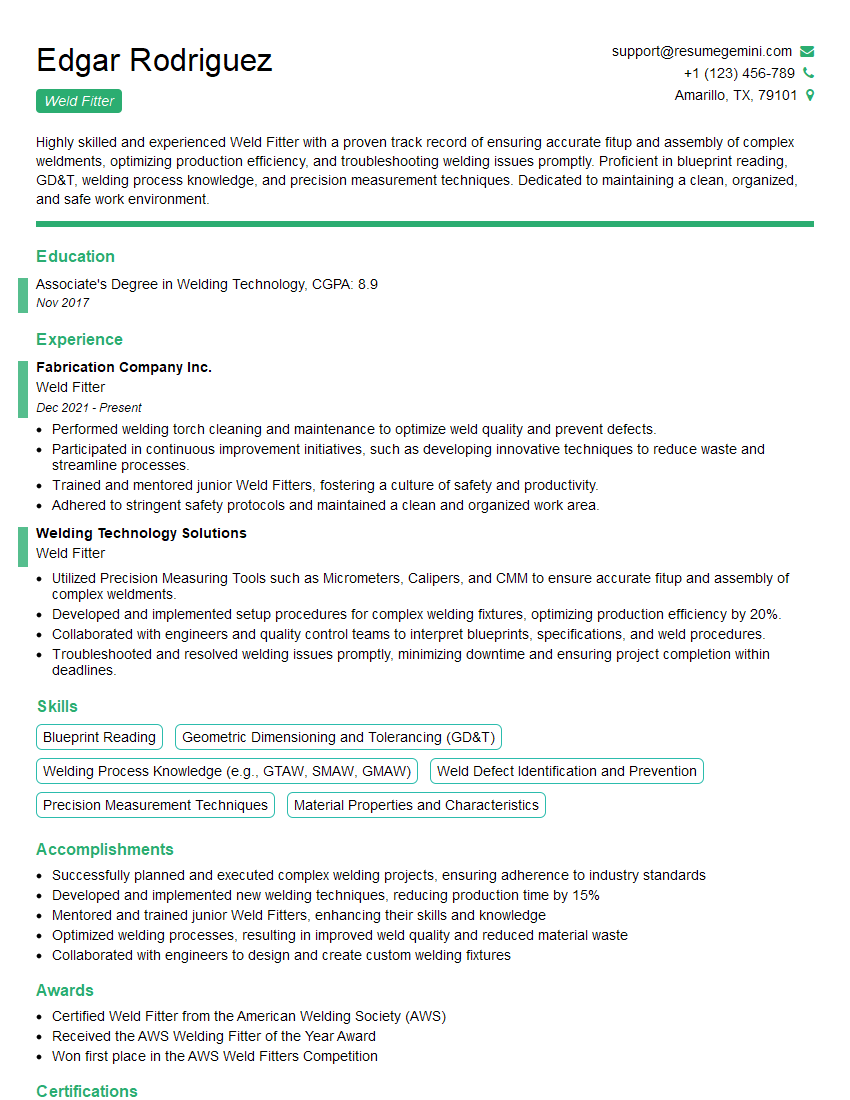

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Weld Fitter

1. Describe the process of welding a pipe joint using the GMAW method?

The GMAW (Gas Metal Arc Welding) process involves:

- Selecting the appropriate wire and shielding gas for the material being welded.

- Preparing the pipe joint by cleaning and beveling the edges.

- Positioning the workpiece in a welding jig or clamp.

- Setting the welding parameters, including voltage, wire feed speed, and travel speed.

- Holding the welding gun at the correct angle and distance from the joint.

- Moving the welding gun along the joint, creating a continuous weld bead.

- Inspecting the weld for quality and making necessary adjustments.

2. What are the common welding defects and how can they be prevented?

- Porosity: Caused by trapped gas during welding. Prevented by using proper shielding gases and ensuring clean base materials.

- Undercut: A groove formed at the edge of the weld. Prevented by maintaining the correct welding parameters and using the correct welding technique.

- Cold Lap: A lack of fusion between two adjacent passes. Prevented by ensuring proper penetration and overlapping.

- Cracking: Caused by excessive heat buildup or residual stress. Prevented by using preheating, post-weld heat treatment, and proper welding techniques.

3. How do you determine the correct welding parameters for a given material and joint configuration?

The selection of welding parameters depends on:

- Material thickness and type

- Joint design

- Welding process

- Desired weld quality

- Reference to welding procedure specifications (WPS)

4. Explain how you would troubleshoot a welding machine that is not producing a stable arc?

- Check for proper grounding.

- Inspect the welding cable and connections.

- Clean the contact tip and nozzle.

- Adjust the wire feed speed.

- Calibrate the welding machine.

5. What is the difference between preheat and post-weld heat treatment?

- Preheat: Applied before welding to reduce the risk of cracking by slowing down the cooling process.

- Post-weld heat treatment: Applied after welding to improve the mechanical properties, reduce residual stresses, and enhance toughness.

6. How do you ensure that a welded joint meets the required specifications and quality standards?

- Follow approved welding procedures.

- Conduct visual, destructive, and non-destructive testing.

- Obtain certifications and meet industry standards.

7. What is the importance of weld inspection?

- Ensures the quality and integrity of welded joints.

- Detects and identifies defects that could compromise the safety and performance of welded structures.

- Meets regulatory requirements and industry standards.

8. What are the different methods of weld inspection?

- Visual inspection: Examination of the weld surface for defects.

- Non-destructive testing (NDT): Methods such as ultrasonic, radiographic, and magnetic particle inspection to evaluate internal weld quality.

- Destructive testing: Physical testing of welded samples to determine strength and ductility.

9. How do you plan and prepare for a welding project?

- Review drawings and specifications.

- Identify materials and equipment.

- Determine welding procedures.

- Plan for safety precautions.

- Schedule tasks and resources.

10. Describe the safety precautions you take while welding.

- Wear appropriate protective clothing.

- Ensure proper ventilation.

- Inspect equipment before use.

- Follow established safety procedures.

- Be aware of potential hazards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Weld Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Weld Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Weld fitters play a vital role in ensuring the accuracy and quality of welded components. Their key responsibilities include:

1. Fitting and Assembling Metal Components

Weld fitters are responsible for fitting and assembling metal components according to specifications. They use precision measuring tools and techniques to ensure that the components fit together accurately and securely.

- Reads and interprets blueprints and engineering drawings.

- Uses precision measuring tools, such as micrometers and calipers, to ensure that components meet specifications.

- Fits and assembles metal components using hand tools and power tools.

2. Measuring and Marking Weld Joints

Weld fitters measure and mark weld joints to ensure that the welds are properly aligned and sized. They use a variety of tools, including tape measures, rulers, and protractors, to make precise measurements.

- Measures and marks weld joints using tape measures, rulers, and protractors.

- Ensures that weld joints are properly aligned and sized.

- Uses a variety of tools to make precise measurements.

3. Tack Welding Components

Weld fitters tack weld components together to hold them in place before final welding. They use a welding machine to create a series of small welds that hold the components securely.

- Uses a welding machine to create tack welds.

- Holds components in place before final welding.

- Ensures that tack welds are strong and secure.

4. Inspecting Welds

Weld fitters inspect welds to ensure that they meet quality standards. They use a variety of tools, including visual inspection, dye penetrant testing, and ultrasonic testing, to identify any defects or inconsistencies.

- Inspects welds using visual inspection, dye penetrant testing, and ultrasonic testing.

- Identifies any defects or inconsistencies.

- Ensures that welds meet quality standards.

Interview Tips

Preparing for a weld fitter interview is crucial to making a positive impression on the hiring manager and demonstrating your qualifications. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific weld fitter position you’re applying for. This will give you a good understanding of the company’s culture, values, and the specific responsibilities and requirements of the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

- Prepare specific questions to ask the interviewer about the company and the position.

2. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the weld fitter role. Be prepared to provide specific examples of your work, showcasing your ability to fit and assemble metal components, measure and mark weld joints, tack weld components, and inspect welds.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide clear and concise examples.

- Be enthusiastic and passionate about your work, and demonstrate your commitment to quality and safety.

3. Be Prepared to Discuss Industry Trends

Weld fitters should be knowledgeable about the latest industry trends and technologies. During the interview, be prepared to discuss your views on emerging technologies and how they might impact the field of welding. This demonstrates your commitment to continuous learning and your ability to adapt to changes in the industry.

- Read industry publications and attend webinars to stay informed about the latest developments.

- Be able to articulate your thoughts on how new technologies might affect the way weld fitters work in the future.

- Show that you are eager to embrace new challenges and learn new skills.

4. Ask Thoughtful Questions

At the end of the interview, asking thoughtful questions shows that you’re engaged and interested in the position. Prepare a few questions that demonstrate your knowledge of the industry and your enthusiasm for the role. This is also an opportunity to clarify any aspects of the job or the company that you’re curious about.

- Ask about the company’s plans for future growth and expansion.

- Inquire about the opportunities for professional development and training.

- Express your interest in the company’s commitment to safety and quality.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Weld Fitter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Weld Fitter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.