Are you gearing up for a career in Weld Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Weld Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

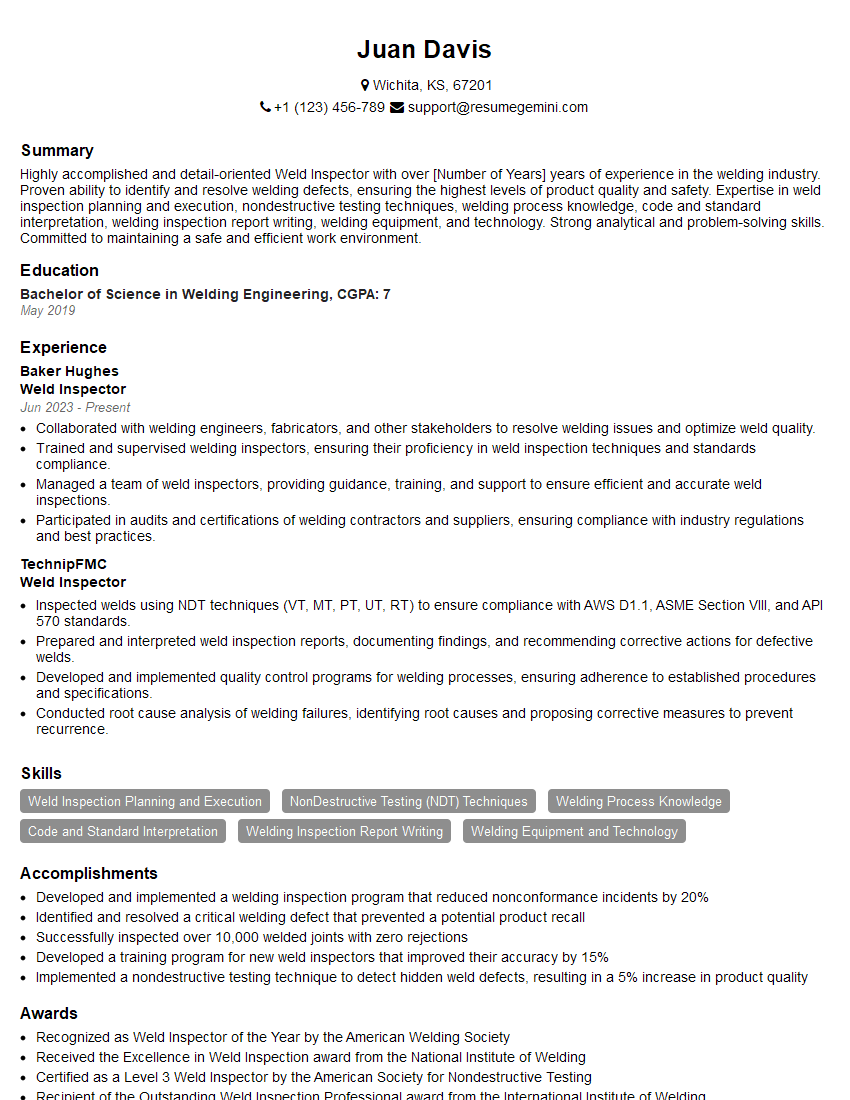

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Weld Inspector

1. What are the different types of weld defects and how do you identify them?

- Porosity: Bubbles of gas trapped in the weld. Can be detected by visual inspection or radiography.

- Lack of fusion: Inclusions of unwelded metal between two fused surfaces. Can be detected by visual inspection or ultrasonic testing.

- Undercut: A groove melted into the base metal adjacent to the weld bead. Can be detected by visual inspection or magnetic particle testing.

- Cracking: A separation of the weld metal or base metal. Can be detected by visual inspection or dye penetrant testing.

- Cold lap: A weld joint where the two surfaces of the metal have not completely fused together. Can be detected by visual inspection or ultrasonic testing.

2. What are the different types of welding processes and when would you use each one?

MIG Welding

- Uses a continuously fed consumable wire electrode.

- Provides high deposition rates and good weld quality.

- Suitable for welding a wide range of materials, including steel, aluminum, and stainless steel.

TIG Welding

- Uses a non-consumable tungsten electrode.

- Provides high-quality welds with minimal distortion.

- Suitable for welding thin materials and critical applications.

Stick Welding

- Uses a consumable electrode that melts into the weld pool.

- Provides high deposition rates and is suitable for welding thick materials.

- Often used in outdoor or field applications where portability is important.

3. What are the different types of weld joints and when would you use each one?

- Butt joint: Two pieces of metal are joined edge-to-edge

- Edge joint: Two pieces of metal are joined side-by-side

- T-joint: A piece of metal is joined perpendicular to another piece

- Corner joint: Two pieces of metal are joined at a 90-degree angle

- Lap joint: Two pieces of metal are overlapped and joined

4. What are the different types of welding codes and standards?

- AWS D1.1: Structural Welding Code – Steel

- AWS D1.2: Structural Welding Code – Aluminum

- AWS D1.3: Structural Welding Code – Stainless Steel

- ASME Boiler and Pressure Vessel Code

- API 1104: Welding of Pipelines and Related Facilities

5. What are the different types of welding equipment and how do they work?

- Welding machines: Provide the electrical power for the welding process.

- Welding torches: Direct the welding arc and shield the weld pool from the atmosphere.

- Welding electrodes: Conduct the electrical current and melt into the weld pool.

- Welding filler metals: Provide additional material to the weld pool to fill gaps and strengthen the joint.

- Welding shielding gases: Protect the weld pool from the atmosphere and prevent oxidation.

6. What are the different types of welding consumables and how do they affect the weld quality?

- Filler Metals: Provide additional material to the weld pool. They come in various compositions and diameters, and can affect the strength, toughness, and corrosion resistance of the weld.

- Shielding Gases: Protect the weld pool from the atmosphere and prevent oxidation. Different gases, such as argon, helium, and CO2, have different effects on the weld quality.

- Flux: A chemical compound that helps remove impurities from the weld pool and improves the weld penetration.

7. What are the different types of weld inspection methods and when would you use each one?

Visual Inspection

- Non-destructive method used to detect surface defects.

- Uses the naked eye or magnifying tools

Radiography

- Non-destructive method used to detect internal defects.

- Uses X-rays or gamma rays to penetrate the weld and create an image.

Ultrasonic Testing

- Non-destructive method used to detect internal defects.

- Uses high-frequency sound waves to penetrate the weld and measure the reflection patterns.

Magnetic Particle Testing

- Non-destructive method used to detect surface and near-surface defects.

- Applies magnetic particles to the weld and detects any discontinuities in the magnetic field.

Dye Penetrant Testing

- Non-destructive method used to detect surface defects.

- Applies a penetrant dye to the weld and detects any discontinuities by observing the dye bleed-out.

8. What are the different types of welding defects and how do they affect the weld strength?

Porosity

- Pores or voids in the weld metal

- Reduces the strength and ductility of the weld

Lack of Fusion

- Areas where the weld metal has not fused with the base metal

- Creates a weak point in the weld

Undercut

- Grooves melted into the base metal adjacent to the weld bead

- Reduces the effective cross-sectional area of the weld

Cold Lap

- Areas where the two surfaces of the metal have not completely fused together

- Creates a weak point in the weld

9. What are the different types of welding symbols and how do you interpret them?

- Basic welding symbols

- Arrow-side welding symbols

- Other side welding symbols

- Combination welding symbols

10. What are the different types of welding procedures and how do you develop them?

- Pre-qualified welding procedures (PQRs)

- Welder qualification test procedures (WPs)

- Procedure qualification records (PQRs)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Weld Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Weld Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Weld Inspectors are responsible for ensuring the quality and safety of welds in a variety of industries, including construction, manufacturing, and transportation. Their key responsibilities include:

1. Inspecting welds for defects

Weld Inspectors use a variety of tools and techniques to inspect welds for defects, such as cracks, porosity, and slag inclusions. They may also perform destructive testing, such as tensile testing and bend testing, to assess the strength and ductility of welds.

- Using visual inspection methods to identify surface defects

- Utilizing non-destructive testing techniques to detect internal flaws

2. Evaluating weld quality

Weld Inspectors evaluate the quality of welds based on their appearance, dimensions, and mechanical properties. They use their knowledge of welding codes and standards to determine whether welds meet the required specifications.

- Analyzing weld geometry to ensure proper dimensions and shapes

- Determining weld strength and integrity through mechanical testing

3. Reporting and documenting inspection results

Weld Inspectors prepare detailed reports and documentation that describe the results of their inspections. They may also make recommendations for corrective actions if any defects are found.

- Creating detailed reports outlining inspection findings and recommendations

- Maintaining accurate records for future reference and traceability

4. Staying up-to-date on welding codes and standards

Weld Inspectors must stay up-to-date on the latest welding codes and standards. This ensures that they are using the most current and accurate information to evaluate weld quality.

- Attending industry conferences and workshops to stay informed about new technologies and best practices

- Studying welding codes and specifications to ensure compliance with industry regulations

Interview Tips

Preparing thoroughly for a Weld Inspector interview is crucial to making a great impression on potential employers. Here are some tips to help you succeed:

1. Research the company and the position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a Weld Inspector.

- Visit the company’s website to learn about their history, products, and services

- Review the job description carefully to identify the key responsibilities and qualifications required

2. Practice answering common interview questions

There are several common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance so that you can deliver clear and concise responses.

- Prepare examples of your experience that demonstrate your skills and qualifications

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

3. Be prepared to discuss your experience and qualifications

The interviewer will want to know about your experience and qualifications as a Weld Inspector. Be prepared to discuss your education, training, and work experience in detail.

- Highlight your experience in welding inspection and non-destructive testing

- Provide examples of projects where you have successfully identified and resolved weld defects

4. Ask questions about the position and the company

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company’s culture and values.

- Ask about the company’s training and development opportunities

- Inquire about the company’s safety policies and procedures

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Weld Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.