Are you gearing up for an interview for a Weld Lay Out Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Weld Lay Out Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

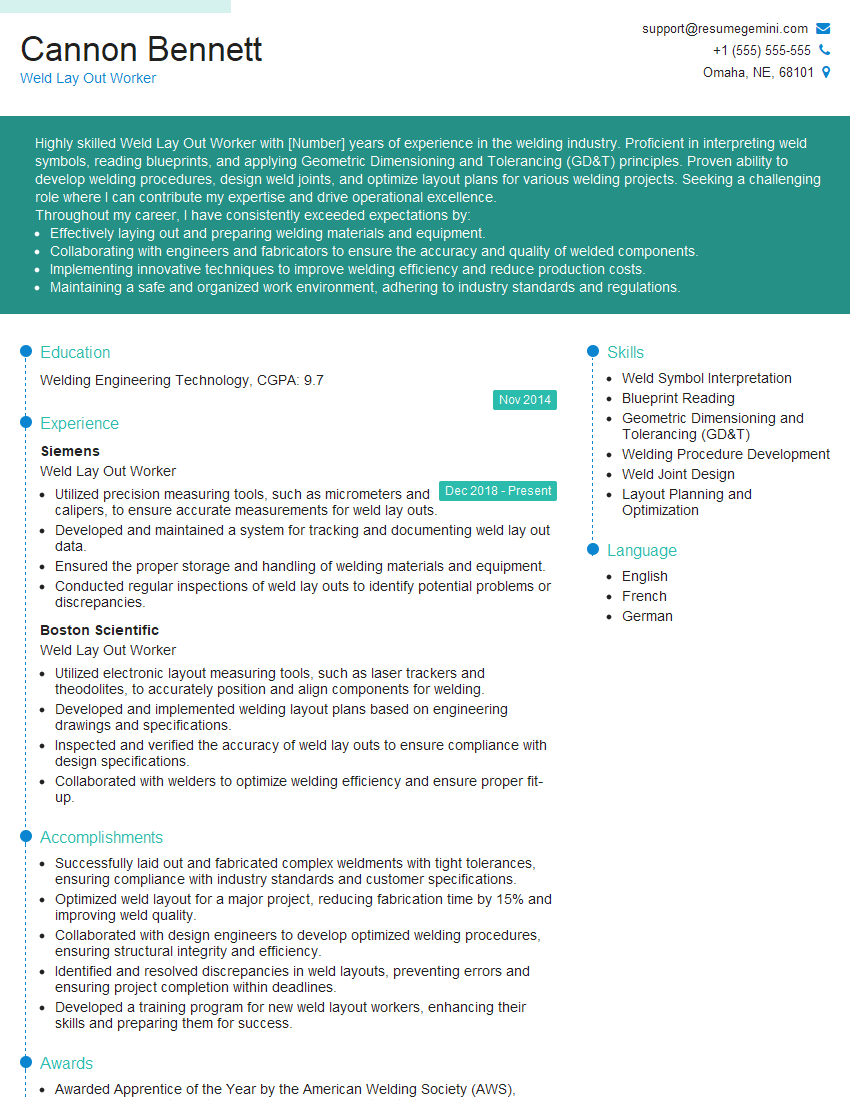

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Weld Lay Out Worker

1. What are the different types of welding processes you are familiar with?

I am familiar with various welding processes including:

- Arc welding (e.g., SMAW, GMAW, GTAW, FCAW)

- Gas welding (e.g., oxy-acetylene welding, oxy-fuel welding)

- Resistance welding (e.g., spot welding, projection welding, seam welding)

- Solid-state welding (e.g., friction welding, ultrasonic welding)

2. How do you prepare metal surfaces for welding?

Surface Cleaning

- Remove dirt, grease, and other contaminants using solvents, detergents, or abrasive cleaning methods.

- Use a wire brush or grinder to remove rust, mill scale, or other surface imperfections.

Edge Preparation

- Bevel, chamfer, or square the edges of the metal to create a proper joint geometry.

- Ensure the edges are clean and free of burrs or other defects.

3. What are the different types of welding joints?

There are various types of welding joints, including:

- Butt joint: Two pieces of metal are joined edge-to-edge.

- Edge joint: Two pieces of metal are joined along their edges.

- Corner joint: Two pieces of metal are joined at a right angle.

- T-joint: Two pieces of metal form a T-shape.

- Lap joint: One piece of metal overlaps the other.

4. How do you set up and operate a welding machine?

To set up and operate a welding machine, I follow these steps:

- Choose the appropriate welding process and equipment.

- Select the correct welding parameters (e.g., amperage, voltage, travel speed).

- Position the workpiece and secure it properly.

- Prepare the welding torch or electrode.

- Start welding and monitor the weld pool.

5. What are the common welding defects and how can they be prevented?

Common welding defects include:

- Porosity: Gas pockets trapped in the weld.

- Cracking: Breaks in the weld metal.

- Slag inclusions: Non-metallic particles trapped in the weld.

- Undercut: Groove melted into the base metal adjacent to the weld.

- Burn-through: Hole melted through the base metal.

To prevent these defects, proper welding techniques, correct parameter settings, and appropriate materials must be used.

6. How do you interpret welding symbols?

Welding symbols provide information about the type of weld, joint preparation, dimensions, and other details. I can interpret these symbols using the following steps:

- Identify the basic weld symbol (e.g., square, triangle, circle).

- Interpret the reference line and arrow.

- Determine the weld type and size.

- Identify any additional information (e.g., joint preparation, tail length).

7. How do you measure and control weld dimensions?

To measure and control weld dimensions, I use various tools and techniques, including:

- Measuring tape or scale for overall dimensions.

- Fillet weld gauges for weld leg length and throat thickness.

- Penetration gauges for weld depth.

- Weld templates or fixtures for precise positioning.

8. What are the safety precautions you take during welding operations?

I prioritize safety in my welding operations by adhering to the following precautions:

- Wear appropriate personal protective equipment (e.g., welding helmet, gloves, apron).

- Ensure proper ventilation to prevent fume inhalation.

- Avoid contact with live electrical circuits.

- Inspect equipment before use and maintain it regularly.

- Follow established safety protocols and procedures.

9. How do you stay up-to-date with the latest welding techniques and technologies?

To stay current with advancements in welding, I actively engage in the following activities:

- Attend industry conferences and workshops.

- Read technical articles and journals.

- Receive training from manufacturers and suppliers.

- Participate in online forums and discussion groups.

- Stay informed about new welding codes and standards.

10. How do you handle working as part of a team in a welding environment?

In a team environment, I contribute by:

- Communicating effectively with team members.

- Sharing knowledge and expertise.

- Collaborating on complex projects.

- Maintaining a positive and supportive work atmosphere.

- Adhering to team goals and objectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Weld Lay Out Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Weld Lay Out Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Weld Lay Out Workers are responsible for ensuring that the welding process is carried out accurately and efficiently. They translate engineering drawings and specifications into detailed instructions for welders, and mark out the workpieces accordingly. They also ensure that the welding equipment is set up correctly and that the work area is safe and organized.

1. Blueprint interpretation and layout

Weld Lay Out Workers must be able to read and interpret blueprints and other engineering drawings. They must be able to identify the different parts of the weldment, the dimensions, and the tolerances. They must also be able to lay out the workpieces so that the welds are made in the correct locations and orientations.

- Interpret blueprints and other engineering drawings to determine the required layout of the weldment.

- Mark out the workpieces using chalk, dye, or other marking tools.

- Ensure that the workpieces are aligned properly and that the welds are made in the correct locations and orientations.

2. Equipment setup and maintenance

Weld Lay Out Workers must be able to set up and maintain the welding equipment. They must be able to select the correct welding process, welding parameters, and welding consumables. They must also be able to troubleshoot the equipment and make repairs as needed.

- Select the correct welding process, welding parameters, and welding consumables.

- Set up the welding equipment and ensure that it is functioning properly.

- Troubleshoot the equipment and make repairs as needed.

3. Work area safety and organization

Weld Lay Out Workers must be able to maintain a safe and organized work area. They must be aware of the potential hazards, such as welding fumes, sparks, and molten metal. They must also be able to use the proper safety equipment, such as welding helmets, gloves, and respirators.

- Maintain a safe and organized work area.

- Be aware of the potential hazards of welding, such as welding fumes, sparks, and molten metal.

- Use the proper safety equipment, such as welding helmets, gloves, and respirators.

4. Quality control

Weld Lay Out Workers must be able to inspect the welds to ensure that they meet the required quality standards. They must be able to identify defects, such as cracks, porosity, and undercut. They must also be able to make repairs as needed.

- Inspect the welds to ensure that they meet the required quality standards.

- Identify defects, such as cracks, porosity, and undercut.

- Make repairs as needed.

Interview Tips

Preparing for a Weld Lay Out Worker interview can be daunting, but with the right strategies, you can increase your chances of success. Here are some tips to help you prepare for and ace your interview:

1. Research the company and the position

This will give you a better understanding of the company’s culture, values, and goals. It will also help you to tailor your answers to the specific requirements of the position.

- Visit the company’s website and social media pages.

- Read articles and news about the company.

- Talk to people who work at the company.

2. Practice your answers to common interview questions

This will help you to feel more confident and prepared during the interview. Some common interview questions for Weld Lay Out Workers include:

- Tell me about your experience with blueprint interpretation and layout.

- What is your experience with setting up and maintaining welding equipment?

- How do you ensure that your work area is safe and organized?

- What are your quality control procedures?

3. Bring a portfolio of your work

This is a great way to showcase your skills and experience to the interviewer. Your portfolio should include examples of your work, such as blueprints, weld layouts, and quality control reports.

4. Dress professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

5. Be yourself

The most important thing is to be yourself and let your personality shine through. The interviewer wants to get to know you and see if you are a good fit for the company. So relax, be confident, and let your personality shine through.

Next Step:

Now that you’re armed with the knowledge of Weld Lay Out Worker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Weld Lay Out Worker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini