Feeling lost in a sea of interview questions? Landed that dream interview for Weld Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Weld Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

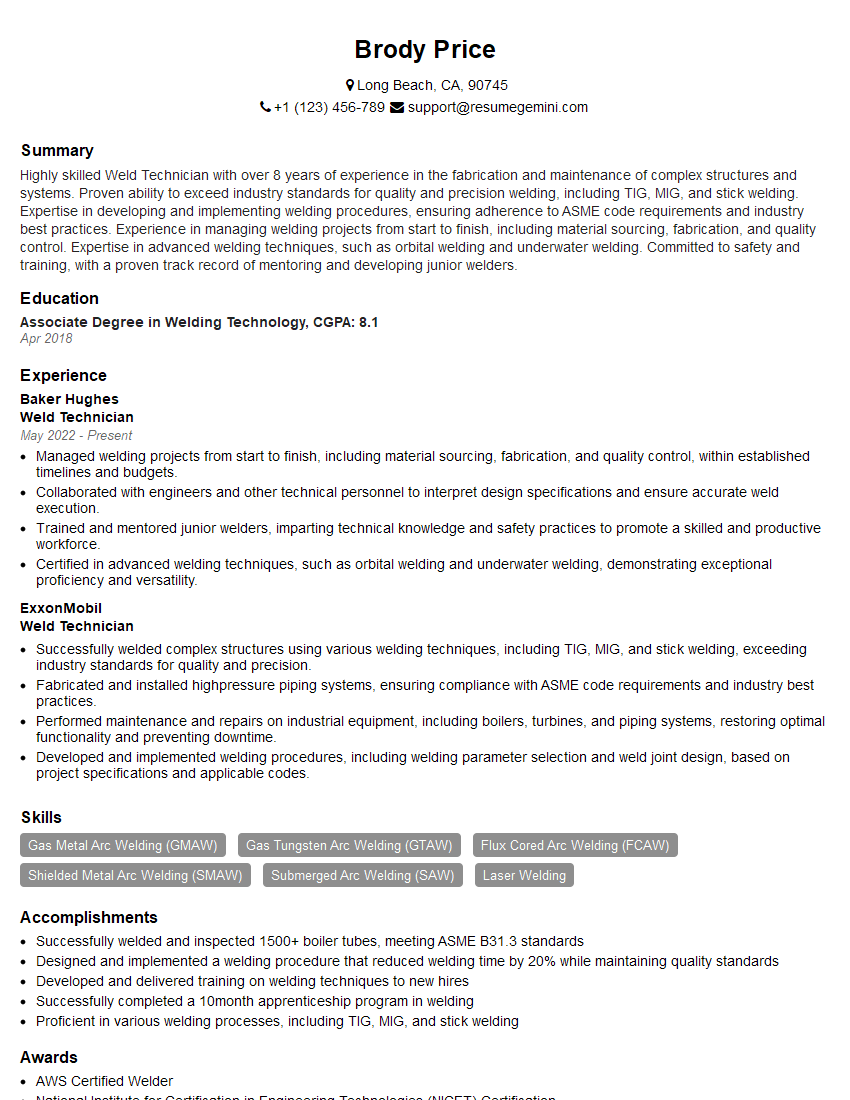

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Weld Technician

1. What welding processes have you used in the past, and which one are you most experienced with?

I have experience in a variety of welding processes, including:

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

- Shielded metal arc welding (SMAW)

- Flux-cored arc welding (FCAW)

I am most experienced with GMAW, also known as MIG welding. I have used this process for over 10 years in a variety of applications, including automotive, construction, and manufacturing.

2. What are the different types of welding joints, and which one is the strongest?

Types of welding joints:

- Butt joint

- Edge joint

- Corner joint

- T-joint

- Lap joint

Strongest welding joint:

The butt joint is the strongest welding joint because it creates a continuous weld along the entire length of the joint. This type of joint is often used in structural applications where strength is critical.

3. What are the most common welding defects, and how can they be avoided?

The most common welding defects include:

- Porosity

- Undercut

- Cold lap

- Crack

- Slag inclusion

These defects can be avoided by using proper welding techniques, such as:

- Using the correct welding process

- Using the correct welding parameters

- Preparing the joint properly

- Using the correct welding consumables

- Inspecting the weld after it is complete

4. What are the different types of welding equipment, and what are their advantages and disadvantages?

There are a variety of different welding equipment available, each with its own advantages and disadvantages. The most common types of welding equipment include:

- Arc welding machines

- Gas welding torches

- Resistance welding machines

- Laser welding machines

- Electron beam welding machines

The type of welding equipment that is best for a particular application will depend on the specific requirements of the job.

5. What are the different types of welding consumables, and what are their applications?

There are a variety of different welding consumables available, each with its own specific applications. The most common types of welding consumables include:

- Welding rods

- Welding wire

- Welding flux

- Welding shielding gas

The type of welding consumable that is best for a particular application will depend on the specific requirements of the job.

6. What are the safety precautions that should be taken when welding?

- Wear appropriate safety gear, including a welding helmet, gloves, and fire-resistant clothing.

- Ensure that the welding area is well-ventilated.

- Keep flammable materials away from the welding area.

- Be aware of the potential for electrical shock.

- Follow all manufacturer’s instructions for the welding equipment.

7. What are the different types of welding certifications, and what are the requirements for obtaining them?

- American Welding Society (AWS) certifications

- National Institute for Certification in Engineering Technologies (NICET) certifications

- American Society of Mechanical Engineers (ASME) certifications

The requirements for obtaining a welding certification vary depending on the specific certification.

8. What are the different career paths available to welders?

- Welding technician

- Welding supervisor

- Welding inspector

- Welding engineer

- Welding instructor

The career path that is best for a particular welder will depend on their individual goals and interests.

9. What are the challenges facing the welding industry today?

- The shortage of skilled welders

- The increasing use of automation in welding

- The need for welders to be certified to meet industry standards

- The need for welders to be aware of new welding technologies

The welding industry is constantly evolving, and welders need to be prepared to adapt to these changes.

10. What are the trends in the welding industry?

- The increasing use of robotics and automation in welding

- The development of new welding technologies, such as laser welding and electron beam welding

- The need for welders to be certified to meet industry standards

- The need for welders to be aware of new welding technologies

Welders who are aware of these trends will be more likely to succeed in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Weld Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Weld Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Weld Technicians are highly skilled professionals responsible for joining metal components using various welding techniques. They play a crucial role in manufacturing, construction, and repair industries.

1. Welding and Joining Metals

Weld Technicians use specialized welding equipment to join metal surfaces together. They select the appropriate welding process based on the type of metal, joint design, and desired strength.

- Perform various welding processes, such as MIG, TIG, arc, and resistance welding

- Ensure welds meet specified standards and specifications

2. Preparation and Setup

Weld Technicians prepare metal surfaces for welding by cleaning, grinding, and tacking. They also set up welding equipment and fixtures to ensure optimal welding conditions.

- Prepare and clean metal surfaces for welding

- Set up and calibrate welding equipment

3. Weld Inspection and Testing

Weld Technicians inspect welds to ensure they meet quality standards. They may perform visual inspections, dimensional checks, and non-destructive testing methods to verify weld integrity.

- Conduct visual inspections of welds

- Perform non-destructive testing, such as dye penetrant testing or ultrasonic testing

4. Troubleshooting and Repairs

Weld Technicians diagnose and repair welding issues. They identify the root cause of problems and implement corrective actions to ensure the equipment is functioning properly.

- Troubleshoot welding equipment and identify welding defects

- Perform repairs and maintenance on welding equipment

Interview Tips

Preparation is key to a successful interview. Here are some tips to help candidates ace their Weld Technician interview:

1. Research the Company and Position

Candidates should thoroughly research the company and the specific Weld Technician position to demonstrate their interest and knowledge. This includes reviewing the company’s website, LinkedIn page, and any recent news or industry articles.

- Learn about the company’s mission, values, and industry standing

- Identify the specific requirements and responsibilities of the Weld Technician position

2. Highlight Relevant Experience and Skills

Candidates should showcase their welding experience, skills, and certifications. They should emphasize their proficiency in various welding techniques, metal fabrication, and quality control methods.

- Quantify their experience by providing specific examples and metrics

- Mention any relevant certifications or training programs they have completed

3. Practice Common Interview Questions

Preparing for common interview questions can help candidates feel more confident and organized during the interview. They should practice answering questions related to their technical skills, problem-solving abilities, and work ethic.

4. Be Enthusiastic and Professional

Candidates should convey their enthusiasm for welding and their desire to join the company. They should dress professionally, maintain good eye contact, and be respectful and polite throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Weld Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!