Are you gearing up for a career in Welder Assistant? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Welder Assistant and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

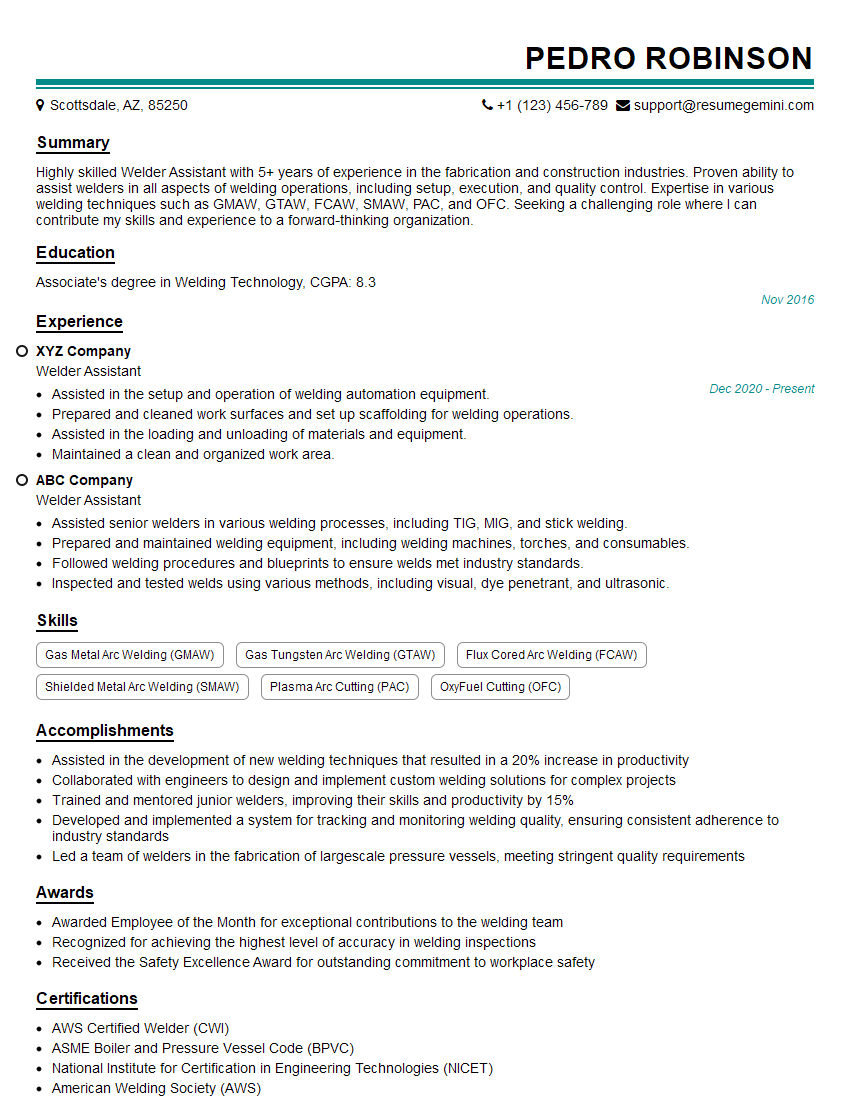

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welder Assistant

1. How do you prepare the weld joint for welding?

To prepare a weld joint for welding, I follow these steps:

- Clean the joint surfaces to remove any dirt, rust, or other contaminants.

- Bevel the edges of the joint to create a V-shape or U-shape groove.

- Fit the pieces together and tack weld them to hold them in place.

- Make sure the joint is free of any gaps or misalignment.

- Check the joint for any defects before welding.

2. What are the different types of welding processes and when are they used?

Shielded Metal Arc Welding (SMAW)

- Uses a covered electrode to create an arc between the electrode and the workpiece.

- Suitable for welding ferrous metals, such as steel and iron.

Gas Tungsten Arc Welding (GTAW)

- Uses a non-consumable tungsten electrode and a shielding gas to create an arc between the electrode and the workpiece.

- Suitable for welding thin metals and non-ferrous metals, such as aluminum and magnesium.

Gas Metal Arc Welding (GMAW)

- Uses a consumable wire electrode and a shielding gas to create an arc between the electrode and the workpiece.

- Suitable for welding ferrous and non-ferrous metals.

Flux-Cored Arc Welding (FCAW)

- Uses a tubular wire electrode that contains flux, which generates a shielding gas and helps to protect the weld.

- Suitable for welding ferrous metals.

3. What are the safety precautions that must be taken when welding?

When welding, it is important to take safety precautions to protect yourself and others from potential hazards, such as:

- Wear appropriate protective clothing, including a welding helmet, gloves, and fire-resistant clothing.

- Ensure proper ventilation to remove welding fumes and gases.

- Keep the work area clean and free of flammable materials.

- Use appropriate grounding techniques to prevent electrical shock.

- Be aware of fire hazards and have a fire extinguisher nearby.

4. What are the common defects that can occur in welding and how can they be prevented?

Common welding defects include:

- Porosity: Caused by the presence of gas bubbles in the weld metal. Prevented by using proper shielding gases and welding techniques.

- Slag inclusions: Caused by the entrapment of slag in the weld metal. Prevented by using appropriate welding techniques and removing slag before welding.

- Undercuts: Caused by excessive heat input. Prevented by using proper welding parameters and techniques.

- Cracks: Caused by stresses in the weld metal. Prevented by using proper welding techniques and post-weld heat treatment.

- Distortion: Caused by the expansion and contraction of the metal during welding. Prevented by using proper welding techniques and fixtures.

5. What is the importance of post-weld heat treatment?

Post-weld heat treatment (PWHT) is a process used to improve the mechanical properties of welded joints by:

- Reducing internal stresses in the weld metal.

- Improving the ductility and toughness of the weld metal.

- Reducing the risk of cracking.

- Improving the overall strength and performance of the welded joint.

6. How do you interpret welding symbols on a drawing?

Welding symbols on a drawing provide information about the type of weld, its size, and its location. I interpret these symbols by:

- Identifying the basic weld symbol.

- Determining the weld size and type.

- Locating the weld on the drawing.

- Understanding any additional symbols or notes.

7. What is the difference between a fillet weld and a groove weld?

- Fillet weld: A weld made at the junction of two surfaces at right angles to each other.

- Groove weld: A weld made in a groove between two pieces of metal.

8. How do you set up a welding machine for a specific welding process?

To set up a welding machine for a specific welding process, such as SMAW or GMAW, I follow these steps:

- Select the appropriate welding process.

- Set the welding parameters, such as voltage, amperage, and wire feed speed.

- Choose the correct welding consumables, such as electrodes or wire.

- Calibrate the welding machine according to the manufacturer’s instructions.

- Test the welding machine to ensure it is functioning properly.

9. How do you troubleshoot common welding problems?

When troubleshooting common welding problems, I follow these steps:

- Identify the problem.

- Check the welding equipment.

- Examine the welding materials.

- Review the welding procedure.

- Make necessary adjustments.

10. How do you stay up-to-date on the latest welding technologies and techniques?

To stay up-to-date on the latest welding technologies and techniques, I:

- Attend welding workshops and conferences.

- Read welding magazines and technical journals.

- Research new welding technologies and techniques online.

- Consult with welding experts and professionals.

- Participate in online welding forums and communities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welder Assistant.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welder Assistant‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welders Assistants are essential members of any welding team, providing a range of support and assistance to ensure that welding operations are performed efficiently and effectively.

1. Assisting Welders

Assist welders by performing a range of tasks such as setting up and taking down welding equipment, positioning and holding materials for welding, and cleaning up the work area.

- Setting up and taking down welding equipment

- Positioning and holding materials for welding

- Cleaning up the work area

2. Preparing Materials

Prepare materials for welding by cutting, shaping, and assembling parts.

- Cutting materials to specified dimensions

- Shaping materials using hand or power tools

- Assembling parts according to welding specifications

3. Inspecting Welds

Inspect welds for defects using visual inspection and other methods.

- Visually inspecting welds for cracks, porosity, and other defects

- Using non-destructive testing methods to detect hidden defects

- Reporting any defects to the welder

4. Troubleshooting Welding Problems

Assist welders in troubleshooting welding problems by identifying potential causes and recommending solutions.

- Identifying potential causes of welding problems

- Recommending solutions to welding problems

- Working with welders to resolve welding problems

Interview Tips

Preparing for a Welder Assistant interview can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company you’re applying to and the specific Welder Assistant position. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website

- Read online reviews

- Talk to people who work at the company

- Review the job description carefully

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with welding?

- What are your salary expectations?

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the industry.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and wrinkle-free

- Avoid wearing casual clothes or revealing clothing

4. Be Enthusiastic and Positive

Employers want to hire people who are enthusiastic and passionate about their work. Show the interviewer that you’re excited about the opportunity to work as a Welder Assistant.

- Smile and make eye contact with the interviewer

- Speak clearly and confidently

- Be positive and enthusiastic about your skills and experience

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Welder Assistant role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.