Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Welder First Class interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Welder First Class so you can tailor your answers to impress potential employers.

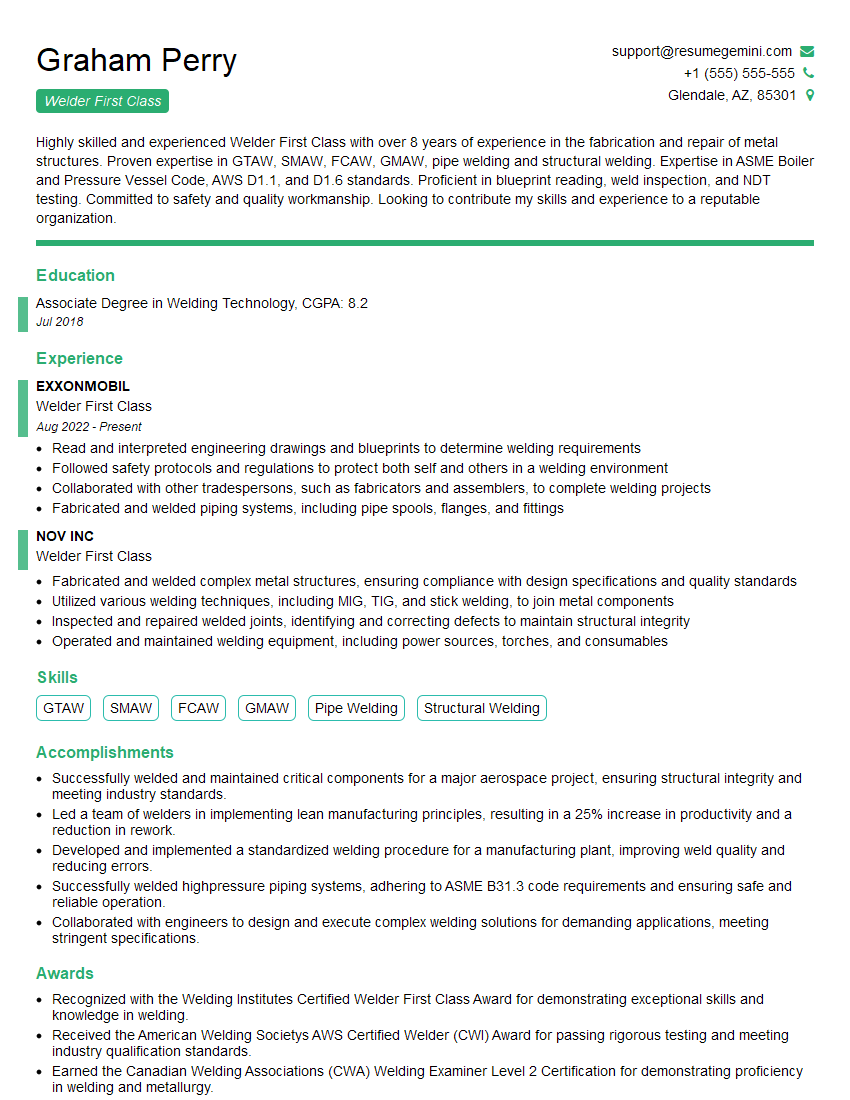

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welder First Class

1. Explain the key differences between SMAW and GMAW welding processes.

- SMAW (Shielded Metal Arc Welding), also known as stick welding, uses a consumable electrode covered with flux to create an arc and weld metal.

- GMAW (Gas Metal Arc Welding), also known as MIG welding, uses a continuously fed wire electrode and shielding gas to create an arc and weld metal.

2. Describe the various welding positions and the challenges associated with each.

- Flat position: Welds made on a horizontal surface, easiest and most common position.

- Horizontal position: Welds made on a vertical surface, requires more skill and control.

- Vertical position: Welds made on an upward-facing surface, demanding due to gravity.

- Overhead position: Welds made on a downward-facing surface, most challenging due to gravity and restricted access.

3. Discuss the factors that affect weld quality, including material composition, joint design, and welding parameters.

- Material composition: Different metals require different welding techniques and parameters due to their varying properties.

- Joint design: The geometry and preparation of the joint can significantly impact weld strength and quality.

- Welding parameters: Voltage, current, travel speed, and shielding gas all affect the weld bead quality.

4. How do you ensure the accuracy and consistency of your welds?

- Using precise measuring tools and maintaining a consistent technique.

- Following welding procedures and specifications.

- Regularly checking and calibrating welding equipment.

- Using welding fixtures and jigs to ensure proper alignment.

5. What are some common welding defects and how can you prevent them?

- Porosity: Caused by trapped gases, can be prevented by proper shielding and avoiding moisture.

- Slag inclusions: Caused by flux residue, can be prevented by proper flux removal.

- Undercut: Caused by excessive welding current, can be prevented by reducing current.

- Cold lap: Caused by insufficient fusion, can be prevented by proper joint preparation and welding with the correct parameters.

6. How do you stay up-to-date on welding technologies and best practices?

- Attending welding conferences and workshops.

- Reading welding journals and industry publications.

- Consulting with welding experts and manufacturers.

- Obtaining industry certifications and training.

7. What are the safety precautions you take when welding?

- Wearing appropriate personal protective equipment (PPE).

- Ensuring proper ventilation to prevent inhalation of fumes.

- Inspecting welding equipment regularly for any defects.

- Storing and handling welding materials safely.

8. How do you interpret welding symbols and specifications?

- Understanding ANSI/AWS welding symbols for joint types, weld sizes, and other specifications.

- Reading blueprints and drawings to accurately follow specified welding requirements.

- Consulting with engineers and fabricators for clarification.

9. What is your experience with welding exotic materials, such as stainless steel or titanium?

Describe specific projects, materials welded, and the techniques used to achieve successful welds.

10. How do you handle working in confined spaces or on complex welding projects?

- Discuss safety precautions and specialized techniques for working in confined spaces.

- Explain how you plan and execute complex welding projects, including coordination with other trades.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welder First Class.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welder First Class‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welders First Class are responsible for welding and fabricating metal structures, components, and equipment in accordance with blueprints and specifications. They use a variety of welding techniques and equipment, including shielded metal arc welding, gas metal arc welding, and gas tungsten arc welding.

1. Welding and Fabricating

Welders First Class are responsible for welding and fabricating metal structures, components, and equipment in accordance with blueprints and specifications. They use a variety of welding techniques and equipment, including shielded metal arc welding, gas metal arc welding, and gas tungsten arc welding.

2. Maintaining Equipment

Welders First Class are responsible for maintaining their welding equipment and ensuring that it is in good working order. They perform regular maintenance tasks, including cleaning and servicing equipment, and replacing worn or damaged parts.

3. Safety

Welders First Class are responsible for following safety procedures and ensuring that their work area is safe for themselves and others. They wear appropriate safety gear and take precautions to avoid injuries and accidents.

4. Troubleshooting

Welders First Class are responsible for troubleshooting and resolving problems with their welding equipment and the parts they produce. They use their knowledge of welding techniques and equipment to identify and fix problems.

Interview Tips

Interviewing for a Welder First Class position can be a daunting experience, but there are some things you can do to prepare and increase your chances of success. Here are a few tips to help you ace your next Welder First Class interview:

1. Research the Company and Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a Welder First Class.

2. Practice Your Answers

Once you have a good understanding of the company and the position, you can start practicing your answers to common interview questions. Anticipate questions about your welding experience, skills, and knowledge. Develop clear and concise answers that highlight your best qualities.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

4. Be Punctual

Punctuality is also important. Arrive on time for your interview and avoid scheduling any appointments or meetings that could make you late.

5. Be Confident

Confidence is key in any interview, but it is especially important for a Welder First Class interview. Welders need to be able to work independently and make sound decisions, so interviewers are looking for candidates who are confident in their abilities.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Welder First Class, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Welder First Class positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.